| Model: | - |

|---|---|

| Brand: | tepu |

| Origin: | - |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | Paper Tube Gumming M , Paper Tube Making Ma , Paper Tube Gumming M |

| Price: |

US $14500

/ pc

|

| Min. Order: | 1 pc |

Product Description

Automatic Toilet Roll Core Tube Making Machine Kraft cardboard-core-tubes machine

Product Description

Feature of this Automatic Toilet Roll Core Tube Making Machine Kraft cardboard-core-tubes machine :

This machine is easily controlled by the panel; electronic counter control the length accurately; high efficiency; frequency;control;

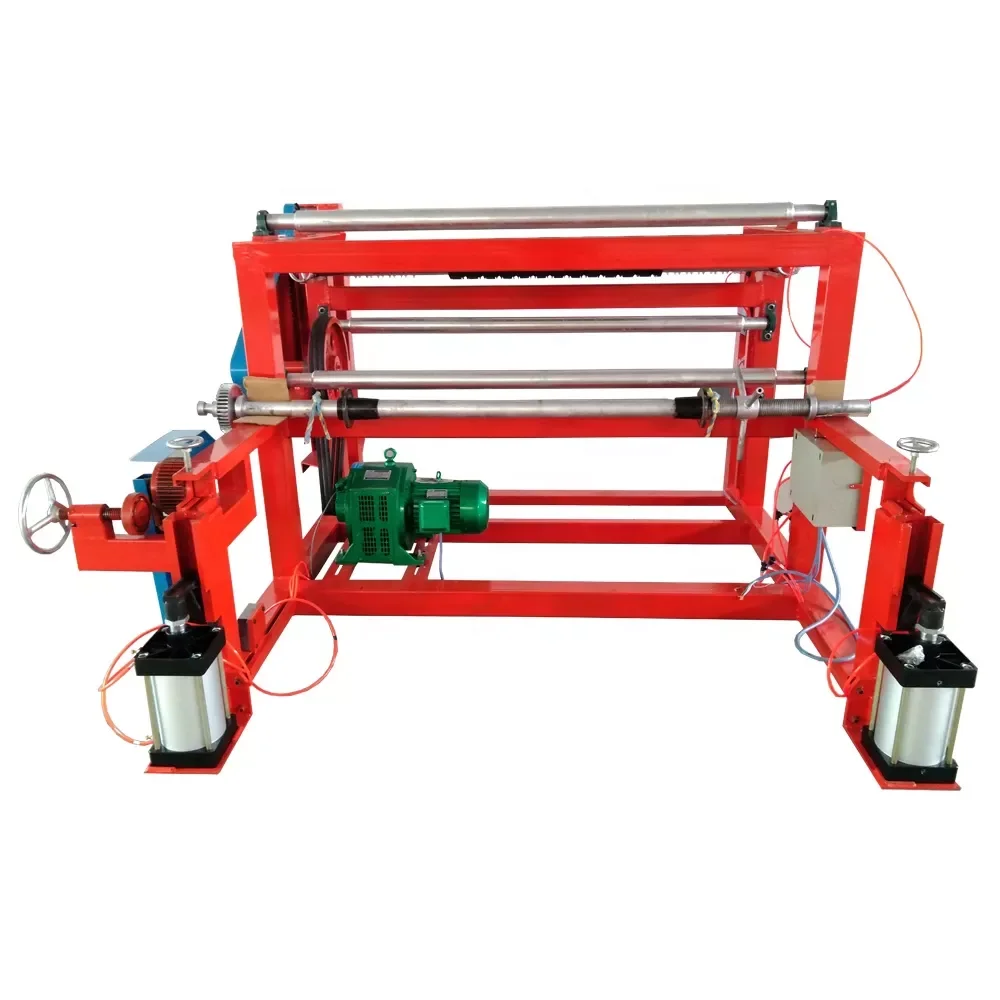

1600A model semi automatic paper slitting machine

|

Cutting speed(min) |

50-120m |

Cutting ablility |

180g-600g |

|

Max width |

1600mm |

Max diameter |

1200mm |

|

Cutting way |

Doulbe circule knife |

worker |

One person |

|

Paper collecting mode |

AB axis synchronous receiving |

Paper correction |

Before and after ,left and right |

|

1) Pairs of circular knife cutting design ,the upper and lower knife can be between 2-1700mm any adjustable width . |

|||

|

2) The paper rolls , the two sides are smooth , never with a flash , the operation is very convenient . |

|||

L200 model spiral paper tube machine

|

Reeling rod diameter |

15-200mm |

Paper layers coiled |

3-16 layers |

|

Tube reeling velocity |

3-16m/min |

Paper tube wall thickness |

1-10mm |

|

Drive method |

Automatic tension anti-dropping chain drive

|

Control method |

Multipoint operation panel |

|

Reeling machine head |

2 head |

Quantity of operators |

2-3 persons |

|

Way of gluing |

Single or double sides |

Reeling rod fixation method |

Clamping type +flanging type bidirectional fixation |

|

Blade cutting |

single round blade |

Cut length method |

Infra-red rays+positioning plate |

|

Main machine power |

7.5kw |

Main machine speed ratio |

Turbine reduction ratio 1:30 |

|

auxiliary |

0.75kw+0.37kw |

Speed regulation method |

Frequency convertion |

|

Main machine size |

2600*1700*1600 |

Power |

380V or customize |

|

A) Setup of more than 80 functions, set mechanical operation conditions at will . |

B)single side or double side gumming |

||

|

C)automatic cutting and automatic tube falling |

D)double infra-red rays main machine conducts automatic speed regulation to ensure tube length with higher precision. |

||

|

E)The frequency conversion speed regulation control can save electricity by 30-60% compared with conventional electromagnetic speed regulation . |

F)low noise .<65 dB |

||

|

G)disc cutter cuts off with square snick and stable performance |

H)gluing way can be single side or double sides. |

||

Packaging & Shipping

Packing & Delivery of Adhesive Tape Slitting Machine

Packing & Delivery of bopp gum tape production line for carton sealing tape

Shipping: by express,by air,by sea

packing: carton box,wooden frame,wooden case,fly case

Shipping:by express,by air,by sea

packing:carton box,wooden frame,wooden case,fly case

Company Information

About US

Dongguan Tepu Automation Equipment Co., Ltd.We are the professional manufacturer for BOPP adhesive tape making machine, bopp tape slitting machine, Adhesive tape cutting machine, adhesive tape coating machine, slitting mahine , rewinding machine , packaging mahcine and so on.We are a high-tech enterprise, which is professional in machinery design & manufacturing.

We have a R&D teamwith experts, senior engineers and professors as key backbone.We are making great efforts to develop new products to meet different requirements. Strict quality control was conducting in every procedure from material sourcing, processing and testing to packing, which guarant our products with reliable performance.Our business got very fast expanding.

We have had a good reputationamong our customers because of our perfect services, quality products and competitive prices. We warmly welcome all customers cooperation with us.

Our Services

Why Choose US?

1. Product quality: Quality tesing records in manufacturing & expriments.

2. Price guarantee: Fine & brand quality materials,parts on machine.

3. Delivery guarantee: Related brochures along with delivery:

operation&maintenance;

installation drawing;

operation books for relater parts of outer supply;

spare parts list and stand accessories.

4. After sales guarantee: The seller is responsible for changing the parts which have the quality problem of the machines in one year,but except from the wearing parts and the quality problem were leaded by wrong operation and other man-made factors,and the quality problem should be confirmed by two sides.

FAQ

1. What is the ratio of raw material to produce BOPP packaging tape?

Normally, 1 ton BOPP film+1.7ton glue + Paper Core and we can get about 2 ton BOPP tape after drying.

2. What is the BOPP film and the coating thickness?

We s est the 22 micron Bopp film and 28micron glue

3. What is the requirement of the glue?

Sloid content 54%+1, pressure sensitive acrylic adhensive

4. What is the production cost of the packaging tape in China?

About USD 0.085 per square meter

5. What is the consumption of the BOPP tape machine,such as electricity ,water, and others?

The 500mm tape machine consume about 10kg water each day,but the power consumption is not fixed.

6. The adhesive Bopp tape machine is manual or automatic?

The tape machine need a air compressor,so it is automatic pneumatic control.

| Payment Terms: | TT |

|---|---|

Member Information

| Dongguan Tepu Automation Equipment Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13590912116 |

| Contact: | Sam Cai (sales) |

| Last Online: | 04 Aug, 2022 |

Related Products of this Company

-

Bopp tape adhesive slitting cutting

US $8600

-

1600mm BOPP packaging tape slitting and

US $10600

-

High Quality BOPP Adhesive Tape Coating

US $25000

-

Adhesive Tape Jumbo Roll Cutting Machine

US $11000

-

BOPP Adhesive Tape Coating Machine

US $25000

-

China Factory made BOPP tape cutting

US $8600

-

High quality Bopp tape slitting cutting

US $12400

-

Fully Automatic Transparent Bopp

US $8600

-

1300mm BOPP adhesive tape jumbo roll

US $8600

-

Three Shafts Automatic Adhesive Tape

US $11000