| Model: | SPK-PL1700-17LT |

|---|---|

| Brand: | SPARK |

| Origin: | Made In China |

| Category: | Industrial Supplies / Industrial Supplies Stocks |

| Label: | High Temperature Sin , Laboratory Heating E , PID Auto Control |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

| Voltage: | AC 380 Plus/minus 10V/50Hz | Usage: | High Temperature Sintering |

|---|---|---|---|

| Heating Element: | MoSi2 Rod | Classification: | Laboratory Heating Equipments |

| Max Temperature: | 500℃ - 1600℃(custom Made) | Temperature Control: | PID Auto Control |

| High Light: |

Continuous Glass Melting Furnace ,PID Control Glass Melting Furnace ,High Capacity Glass Melting Furnace |

||

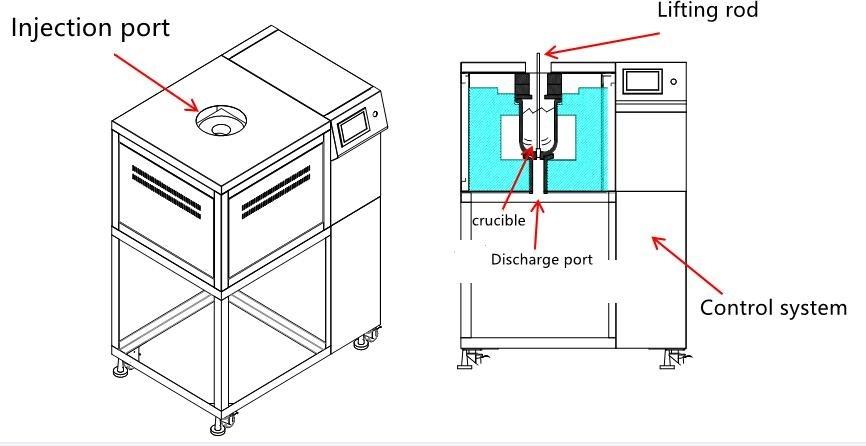

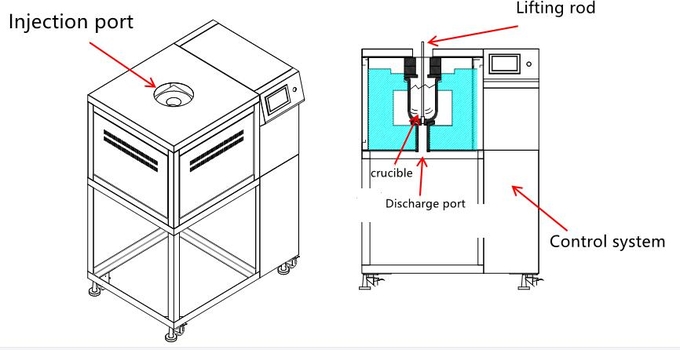

SPK-PL1700-17LTI

1700 ℃ quartz glass melting furnace

SPK-PL1700-17LTI series 1700 ℃ high temperature vacuum atmosphere furnace is shown in the figure, which integrates the control system and furnace. The furnace lining is vacuum formed multi-layer high-purity alumina, and the silicon molybdenum rod is used as the heating element to ensure the uniformity of furnace temperature.

major function

Use silicon molybdenum rod as heating element; It is a special equipment specially developed for the laboratories of colleges and universities, scientific research institutes and industrial and mining enterprises to sinter, melt, analyze and produce ceramics, metallurgy, electronics, glass, chemical industry, machinery, refractories, new material development, special materials, building materials, metals, nonmetals and other chemical and physical materials.

The control panel is equipped with intelligent full touch screen intelligent temperature regulator to control the power switch at any time, so as to observe the working state of the system at any time and control the power in real time. This product adopts reliable integrated circuit, with good working environment and anti-interference. The shell temperature of furnace body at the highest temperature is ≤45 ℃ greatly improves the working environment. Microcomputer program control, programmable curve, fully automatic temperature rise / drop, temperature control parameters and programs can be modified during operation, which is flexible, convenient and simple to operate.

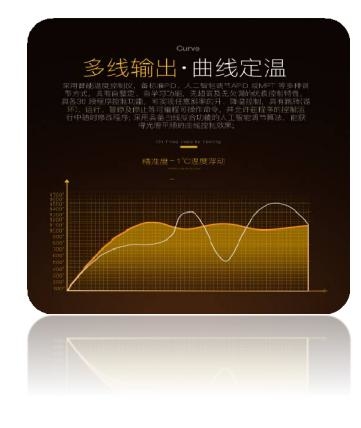

Temperature control accuracy: ± 1 ℃ without overshoot Constant temperature accuracy: ± 1 ℃, furnace temperature uniformity: ± 3 ℃. The heating rate is fast, and the fastest heating rate is ≤ 10 ℃ / min. Intelligent full touch-screen temperature controller is adopted, and apid adjustment mode is adjusted by artificial intelligence. It has self-tuning and self-learning functions, excellent control characteristics without overshoot and undershoot, pre stored 10 groups and 30 sections of program control function, which can realize the rise and fall temperature control of any slope, programmable / operable commands such as jump (cycle), operation, pause and stop, and allows the program to be modified at any time during the control operation of the program; Using the artificial intelligence adjustment algorithm with curve fitting function, the smooth curve control effect can be obtained.

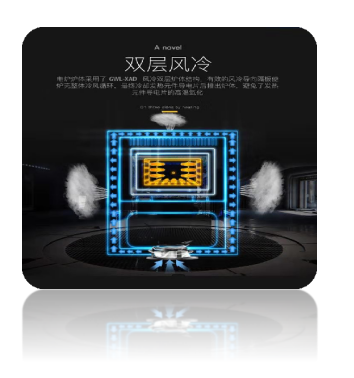

All furnace materials are vacuum formed high-purity alumina light gathering materials, with high operating temperature, small heat storage capacity, rapid heat and cold resistance, no crack, no slag falling and good thermal insulation performance (the energy-saving effect is more than 60% of that of the old electric furnace). Reasonable structure, inner and outer double-layer furnace sleeves, air cooling and heat dissipation, which can greatly shorten the test cycle.

The integrated modular control unit is adopted with accurate control accuracy, and the double loop control and double loop protection are designed, which have the protection of overshoot, overshoot, undershoot, segment couple, lack of phase, overpressure, overcurrent, overtemperature, current feedback, soft start and so on.

The electric furnace body adopts the air-cooled double-layer furnace body structure, and the effective air-cooled guide diaphragm makes the overall cold air circulation of the furnace shell. Finally, after cooling the conductive sheet of the heating element, it is discharged from the furnace body, avoiding the high-temperature oxidation of the conductive sheet of the heating element; Ensure a good working environment.

technical parameter

| NAME | 1700 ℃ Quartz Glass Melting Furnace |

| Maximum service temperature | 1650℃ |

| Long term service temperature | ≤1600℃ |

| Temperature control range | 200-1650℃ |

| Voltage power | 380V 3Phase 40KW |

| Temperature measuring element | Type B thermocouple |

| Crucible material | Zircon quartz |

| Crucible volume | 17L |

| Installation position of heating element | Annular heating around the furnace |

| control accuracy | ± 1 ℃ (controlled by integrated circuit without overshoot) |

| Feeding and discharging mode | Upper feed, lower discharge |

| Furnace temperature uniformity | ± 3 ℃ |

| Heating rate | The heating rate can be adjusted freely. The adjustment range: the fastest heating rate is 10 ℃ per minute and the slowest heating rate is 1 ℃ (1 ℃ / h) per hour |

| Heating element | High quality silicon molybdenum rod is used as heating element |

| Control mode | Spk-101ep embedded operating system, Chinese and English interchangeable graphical interface, 7-inch true color touch screen input, intelligent man-machine dialogue mode; |

| Temperature curve setting | 15 temperature curves can be pre stored in the main heating, and 30 sections of "time temperature curve" can be set for each curve for real-time monitoring and dynamic and real display of "time temperature curve" |

| Furnace structure | The electric furnace body adopts the internationally advanced air-cooled double-layer furnace body structure, and the effective air-cooled guide diaphragm makes the overall cold air circulation of the furnace shell. Finally, it is discharged from the furnace body after cooling the conductive sheet of the heating element, avoiding the high-temperature oxidation of the conductive sheet of the heating element; Ensure a good working environment |

| Furnace body | The furnace body is processed by CNC machine tool and made by polishing, polishing, pickling, phosphating, spraying plastic powder and high-temperature baking. It has two-color matching, novel and beautiful appearance, and has the advantages of oxidation resistance, acid and alkali resistance, corrosion resistance, high temperature resistance and easy cleaning |

| Refractory |

The furnace lining is made of vacuum formed high-purity alumina lightweight material. The light hollow ball aluminum oxide plate is used at the positions where the materials are easy to touch and load (furnace mouth and furnace bottom). It has high service temperature, small heat storage capacity, rapid heat and cold resistance, no crack, no slag falling and good thermal insulation performance (the energy saving effect is more than 60% of that of the old electric furnace) |

| Thermal insulation material | Three layers of insulation are adopted, namely alumina fiber cotton, alumina fiber board and alumina (polycrystalline) fiber board. The energy-saving effect is more than 80% of that of the old electric furnace. |

| Furnace shell temperature | For long-term use without boiler shutdown, the shell temperature is less than 45 ℃ |

| Protect | The integrated modular control unit is adopted, with accurate control accuracy, and dual loop control and dual loop protection are designed, with protection against overshoot, overshoot, undershoot, segment couple, phase loss, overpressure, overcurrent, overtemperature, current feedback, soft start, etc |

| Control | Using closed-loop technology, thyristor module trigger control, phase-shifting trigger control or zero crossing trigger mode, the output voltage, current or power are continuously adjustable, with the characteristics of constant voltage, constant current or constant power; The current loop is the inner loop and the voltage loop is the outer loop. When the load is suddenly applied or the load current exceeds the current limit, limit the output current of the voltage regulator within the rated current range to ensure the normal operation of the output and voltage regulator; At the same time, the voltage loop also participates in the regulation, so that the output current of the voltage regulator is limited within the rated current range, and the output current and voltage are kept constant on the premise of sufficient regulation margin; So as to protect the heating element, avoid the impact of excessive current and voltage, and achieve safe and reliable control effect and control accuracy. |

| Display parameters | Output voltage, real time, temperature, time, etc |

| Button | Imported buttons are adopted, with a service life of more than 100000 times and LED indicators. |

| Multiple curve input | Multi segment program control function, which can input multiple curves at the same time, and can be called arbitrarily when in use. |

| Remarks |

1. In order not to affect the service life of the electric furnace, we s est that the maximum heating rate and cooling rate are 10-20 ℃ / min (if the temperature rises too fast at high temperature, the service life of the heating element will be shortened); 2. This box furnace does not use vacuum sealing structure, so flammable and explosive gases cannot be introduced; 3. If the coating is slightly cracked after the furnace is used, it will not affect the normal use of the furnace; 4. Corrosive gas shall not be introduced; 5. The high-temperature solution shall not leak to the furnace bottom, and the base plate or aluminum oxide powder can be used for isolation; |

| Packing list | One electric stove, one set of heating elements, one pair of high-temperature gloves, one manual, one certificate of conformity, one factory test report and one sales delivery note. |

After sales service commitment

Spark industry (Henan) Co., Ltd. is unique in its operation and service in the field of thermal engineering. Years of experience and strict user management make it a supplier who can try his best to meet all the requirements of customers.

We integrate product development, design, processing, assembly and sales. We are an innovative enterprise with independent R & D and production capacity in China. Therefore, when you buy any spark products, you have received reliable and lifelong product after-sales service. We hereby make the following commitments:

1, All equipment provided by our company are guaranteed free of charge for 1 year (excluding consumables and human faults), and the touch control system is guaranteed for 2 years with lifelong after-sales service. We will accurately and timely provide the spare parts that customers want to order and provide all kinds of services that customers need, and have the obligation and responsibility to answer any questions raised by customers at any time.

2, Our company is responsible for the customer's training and lifelong technical support to ensure that any equipment sold operates without failure.

3, After the order is issued, we will establish contact with the customer. At the same time, our company will guide the customer's system layout, so as to start up and debug the customer in time and make the customer satisfied with our every service.

4, In case of equipment failure, we will make service response within 24 hours and timely solve the problems for customers in the form of voice telephone, video communication and door-to-door service.

5, We should establish a cordial and good cooperative relationship with customers, learn from each other in cooperation, listen to customers' s estions and respect customers' opinions. During equipment installation, we will train the equipment users in a systematic and standardized way.

Tag:

MoSi2 Rod High Temperature Furnace,

| Payment Terms: | T/T, L/C |

|---|---|

Member Information

| SPARK INDUSTRY (HENAN) CO.,LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15514573698 |

| Contact: | Pop Du (staff member) |

| Last Online: | 17 Aug, 2022 |

Related Products of this Company

-

MoSi2 High Temperature Electric Heating

-

Zirconium Titanium ASTM B387 Molybdenum

-

Silicon Carbide Resistance Heater Single

-

High Temperacture White 99.7% Alumina

-

Corrosion Resistance ASTM B168 Inconel

-

Cr20Ni30 Nickel Chromium Alloys Wire

-

Stainless Steel Electric SiC Heating

-

Length 300 ~ 2000mm Electric Radiant

-

Sintering Tunnel Electric High

-

Three-Phase 1450 ℃ Silicon Carbide