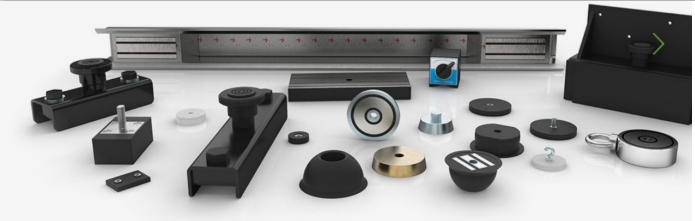

Making precast magnet includes a lot of fastening work: fastening formwork on mold table, fixing wire boxes at designated spots etc. Traditional practice would be drilling holes and then insert pins for fastening. To be more exact: drilling holes both on formworks and mold table, fastening by hammering pins into holes. Afterwards, these pins need to be pulled out to detach those magnetic formwork, wire boxes for further use. The process is time-consuming and those holes on mold table reduces its life span.