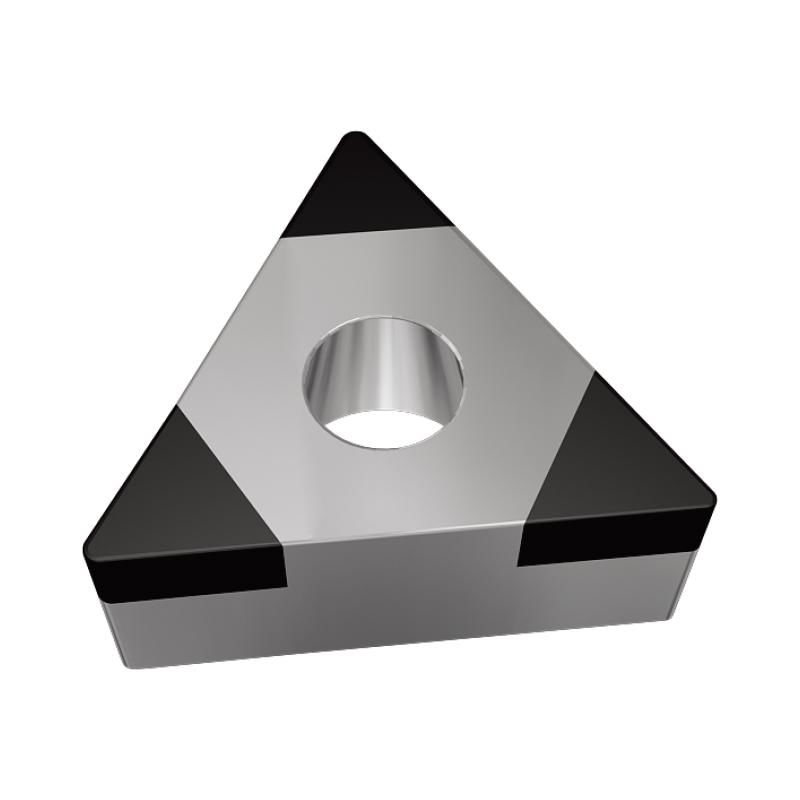

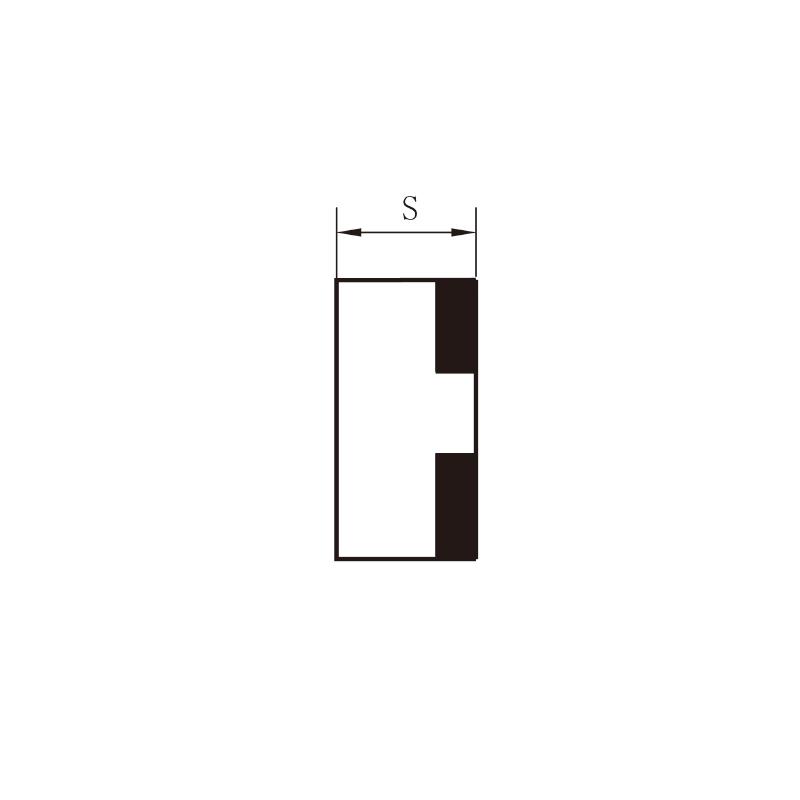

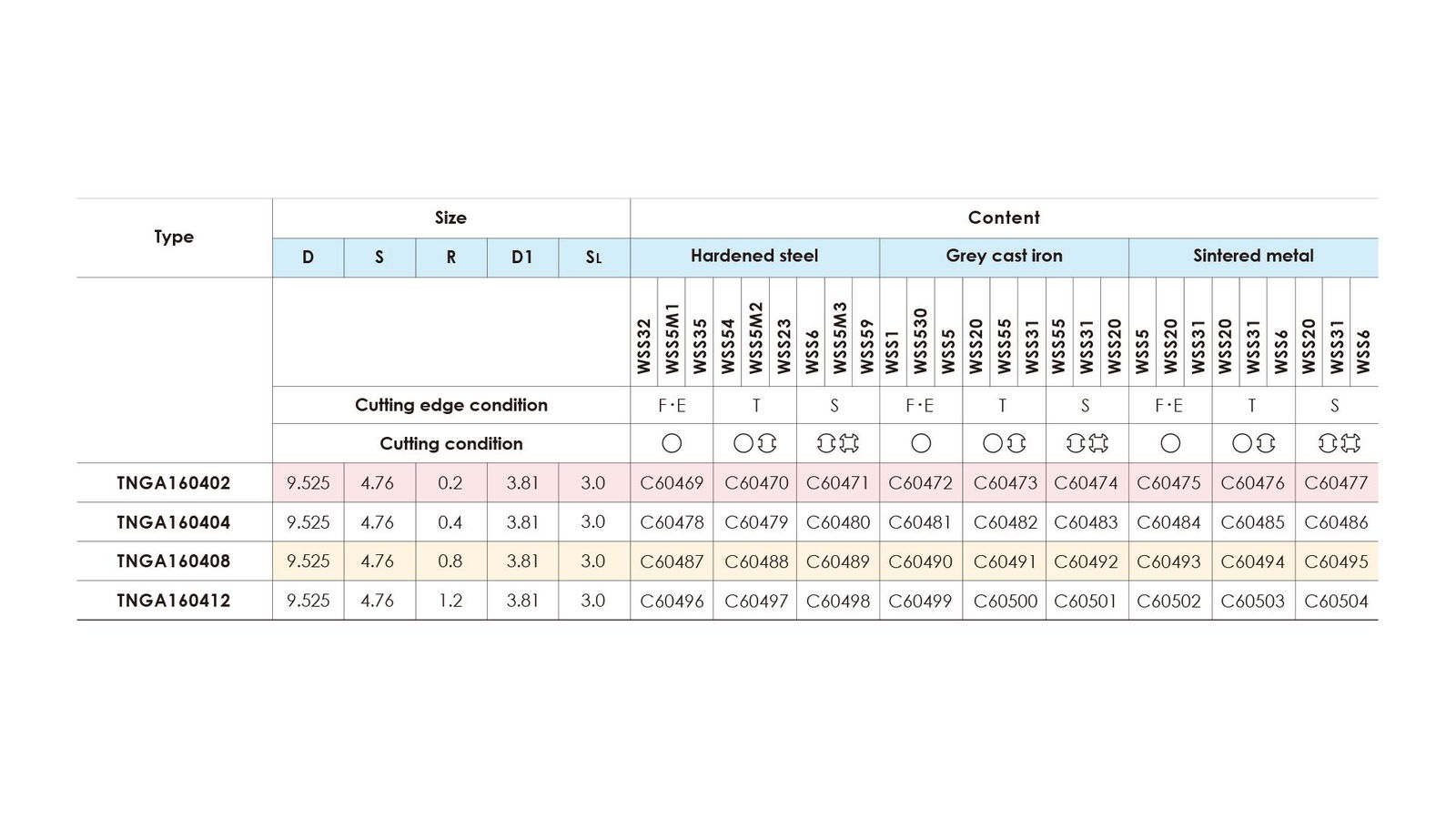

CBN blanks are manufactured from cubic boron nitride crystals utilizing an advanced high temperature, high-pressure process. The cubic boron nitride crystals are sintered together with a binder phase and integrally bonded to a tungsten carbide substrate. The binder phase, usually either a metallic or ceramic matrix, provides chemical stability, enabling the CBN qualities to be utilized in high-speed machining environment. The substrate in the CBN blanks provides the high impact resistance necessary for the depth of cuts and high speed associated with machining of hardened ferrous materials. CBN cutting tools offer excellent heat dissipation and wear resistance. Cutting tool geometries can be prepared to withstand interrupted cut. CBN tools offer the following benefit: (a) machine-hardness and heat-treated steels, (b) an excellent surface finish that allow eliminated grinding, (c) high productivity rate that can be more than four times higher than that in grinding, (d) grat resistance to abrasion which is twice that ceramics and ten times than that of carbide. CBN tools are recommended for machining cast iron including compacted graphite iron (CGI), sintered iron and super alloys hardened steel.