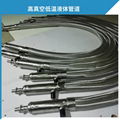

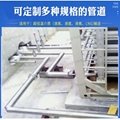

1. Adopt the Japanese high vacuum pumping and bandaging technology, and carry on the process of heating-heating rough pumping-heating high vacuum pumping-cold high vacuum pumping-sealing according to the relevant regulations. Adopt automatic high vacuum oil diffusion pump equipment. 2. The structure design is unique and reasonable, using the reasonable compensation structure, the performance is stable, the movement is reliable. The balance strength design is adopted in the insulation support of the end of the pipeline, which ensures the double reliability of the insulation and strength. 3. Reasonable structure, no perspiration and low evaporation rate. The company in Japan's high vacuum multi-layer insulation vessel manufacturing technology on the basis of continuous optimization of design and manufacturing process, forming a unique vacuum tube sealing technology. 4. Use High quality thermal insulation material. In order to achieve the vacuum tube good thermal insulation and radiation resistance, the company used overseas production of ultra-fine glass fiber coating and ultra-thin sealing materials. In order to slow down the vacuum attenuation of vacuum tube interlayer, an adsorption capsule is set up, and the adsorption material of United States carbon is selected.