| Model: | - |

|---|---|

| Brand: | Sunny Steel |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | - |

| Price: |

US $1000

/ pc

|

| Min. Order: | 10 pc |

Product Description

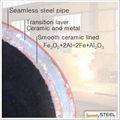

Cast basalt compound can be mainly used as abrasive material and ash handling system like chute slip trough, funnel, silos, a variety dust catcher, revolving-flow machine, various scraper transport planes, all the feeder liner. Laying the ground all types of chemical plants, it can be for lining picking tank or storage of corrosive substance of the storage room.

According to customer requirements along with cast basalt production technology and we can offer various specifications and various shape to meet client’s need.

• Friction Resistance : As more material is passed over Cast Basalt it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

• Impact Resistance : Direct Impact Resistance at 90 degree is low like all other ceramics, but it can be increased with proper installation by reducing the angle of impact. Cast Basalt is the best wherever sliding abrasion exists. Moreover, external impact strength of composite basalt pipe (enclosed in M.S. Shell) is always more than that of bare Ni-hard Pipe.

• Chemical Resistance : Cast Basalt is almost absolutely acid/alkali resistant (except Hydrofluoric Acid) and hence corrosion resistant.

• Weight and Sizes : Basalt Tiles are available in regular shape square of 200 x 200 x 30 mm thick, weighing approx. 90 kg/sq m; whereas bends and pipes are lined using Basalt Cylinders of various standard sizes from 50NB upto 500NB.

• Temperature : Cast Basalt withstands temperature up to 4500°C

We offer cast basalt tile lined elbows for coal bunkers and chutes. These cast basalt tiles are bedded as well as jointed in cement/special bonding agents like resins depending upon application. These tiles mostly find application in automotive industry and are designed to provide long-lasting lining and enhancement to involved operational life cycle for both plant as well as equipment.

Cast basalt lined pipes is a mineral material produced by melting natural basalt at a temperature of approximately 1300°C, followed by casting into moulds. This contributes to its superb physical and chemical properties.

Data of cast basalt tiles

Chemical component

| SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | K2O | Na2O | FeO | P2O5 | MnO |

|---|---|---|---|---|---|---|---|---|---|---|

| 42-45% | 13-16% | 13-14% | 0.022 | 10-12% | 10-11% | 0.045 | 0.045 | 13-14% | <1% | <1% |

Physical property

| NO. | ITEM | PERFORMANCE VALVE |

|---|---|---|

| 1 | Specific gravity | 2.9-3.05gm/cc |

| 2 | Compressive strength | 3000-4500kg per sq cm(min) |

| 3 | Bending strength | 300kg per sq cm(min) |

| 4 | Water Absorption | 0 |

| 5 | Solubility in Acids | 0.006 |

| 6 | Hardness | 8(MIN.)Moh Scale |

| 7 | Modules of elasticity | 11.1×104N/mm2 |

| 8 | Expansion coefficient (room temperature to 60°C) | 0.75×10-5/K |

| 9 | Thermal Conductivity | 1.15W/mk |

| 10 | Special Heat Capacity | 0.8kj/Kg.K |

| 11 | Highest Temperature For application | 350°C |

Advantages:

* Utilizing Cast Basalt enhances and improves operational life of plants.

* These are best suited for jobs where extensive cutting is needed.

* We can also deliver pre-cut tailored tiles based on the considerations of vibration, impact and other factors at client’s end.

Member Information

| Shanghai AnKeFu International Trade Co.,Ltd. | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 16927033 |

| Contact: | Sum Xu (Manager) |

| Last Online: | 01 Feb, 2023 |

Related Products of this Company

-

Elbows, Pipe elbows, Elbow fittings

US $10

-

Cast Basalt Lined Lateral

-

Cast Basalt Lined Steel Pipe Tee

US $1000

-

End Cap, Cap fittings

US $10

-

Tubes for Heat Exchanger and Condensers

US $60

-

ASTM A335 P22 alloy steel pipe

US $66

-

ASTM A213 T11 Seamless alloy pipe

US $1000

-

ASTM A213 T22 alloy pipe

US $1000

-

Ceramic-Lined Pipes & Elbows

US $100

-

ASTM A335 P91 High pressure boiler pipes

US $88