| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | GSK RMD08 , GSK RMD20 , GSK RB50 |

| Price: |

-

|

| Min. Order: | - |

Product Description

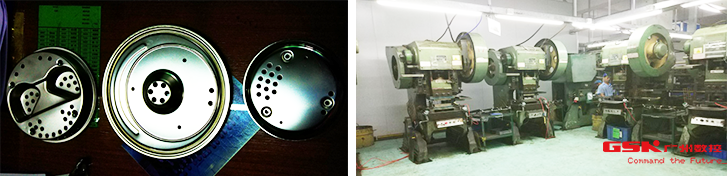

GSK RMD08 robot application, stamping inner container automatic production

robot replaces manual labor, and completes workpiece transportation and loading and unloading between three 63-ton punch presses and loading and unloading machines; there are many product models, a single production batch is not large, and the robot fixtures are highly versatile. It is necessary to realize the grabbing and loading of different products.The processing time of the special machine for production is 6 seconds, and the production capacity of the production line: 350 pieces/hour;

Work object solution

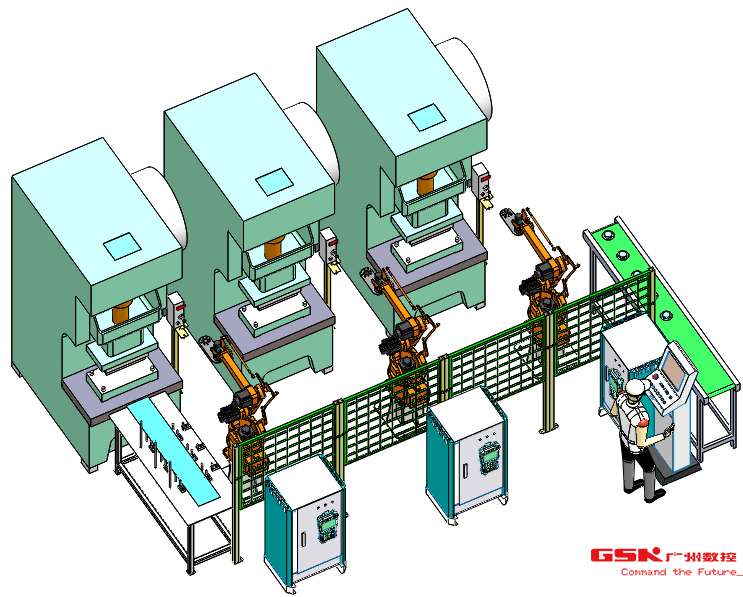

3 sets of RMD08 handling robots, 3 sets of flexible grippers, supporting 63 tons of punching machines, upper and lower hoppers, complete blank loading, production workpiece transportation and finished product unloading; robot grippers adopt a compatible and flexible design, and adjust each suction cup The location can realize the production of all workpieces by adsorption, grabbing, loading and unloading.model layout

The application effect

is compatible with the design of flexible manipulators, which solves the problem of multi-model and small-batch production on the same production line with less transformation costs; the robot operation is closely coordinated with the punching machine, and the work is stable, maximizing production efficiency and reducing production costs. .

Application rendering

Dongguan Hypertron Intelligent Technology Co., Ltd

specializes in the production of special manipulators for injection molding machines and other automation equipment, spot welding robots, handling robots, general-purpose robots, and spraying robots, which can improve automatic productivity, production stability, production efficiency and Quality, and appropriately reduce production personnel, so that the injection molding production plant has a more competitive advantage in the market.The company provides customers with the best overall automation solutions and services from product planning and design, manufacturing, assembly, sales, and service, and is widely used in electronics, communications, automobiles, home appliances and other fields.Provide high-quality, high-efficiency, and reasonably priced automation products for the plastic industry.

Agent for precision CNC lathes CNC milling CNCmachines grinding machines

General items: research and development of intelligent robots; manufacturing of industrial robots; installation and maintenance of industrial robots; sales of industrial robots; sales of intelligent basic manufacturing equipment; manufacturing of intelligent basic manufacturing equipment; manufacturing of industrial automatic control system devices; sales of industrial automatic control system devices; Manufacturing; sales of intelligent instruments and meters; manufacturing of power electronic components; sales of power electronic components; general mechanical equipment installation services; network and information security software development; Import and export of goods; import and export of technology.

Kennethchui Engineer

13715334662

WeChat ID: kennethchui88

Email: everwinmold@163.com

QQ: 2819840570

| Embed HTML Code: | |

|---|---|

Member Information

| Dongguan Haibochuang Intelligent Technology Co., Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13202262841 |

| Contact: | xuguomin (manager) |

| Last Online: | 22 Oct, 2023 |

Related Products of this Company

-

GSK RB15L robot application, curtain

-

GSK RH06B1-1490 seven-axis industrial

-

BRTB08WDS1P0 One-axis servo manipulator

-

GSK RB08 handling robot application of

-

BRTNN15WSS3P/BRTNG15WSS3P Three axis

-

GSK RB08 robot application auto parts

-

Dalian 6180X1500 ordinary lathe equipped

-

GSK RMD08 handling robot vacuum inner

-

Yunnan Machine Tool CY-VMC850LD

-

GSK RH06 welding robot application on