| Model: | BSP-250 |

|---|---|

| Brand: | Brightsail |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cutting & Fold-bend Machine |

| Label: | Air Classifier Mill , Grinding Machine , Sugar grinding machi |

| Price: |

US $14000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Introduction BSP Air Classifier Mill:

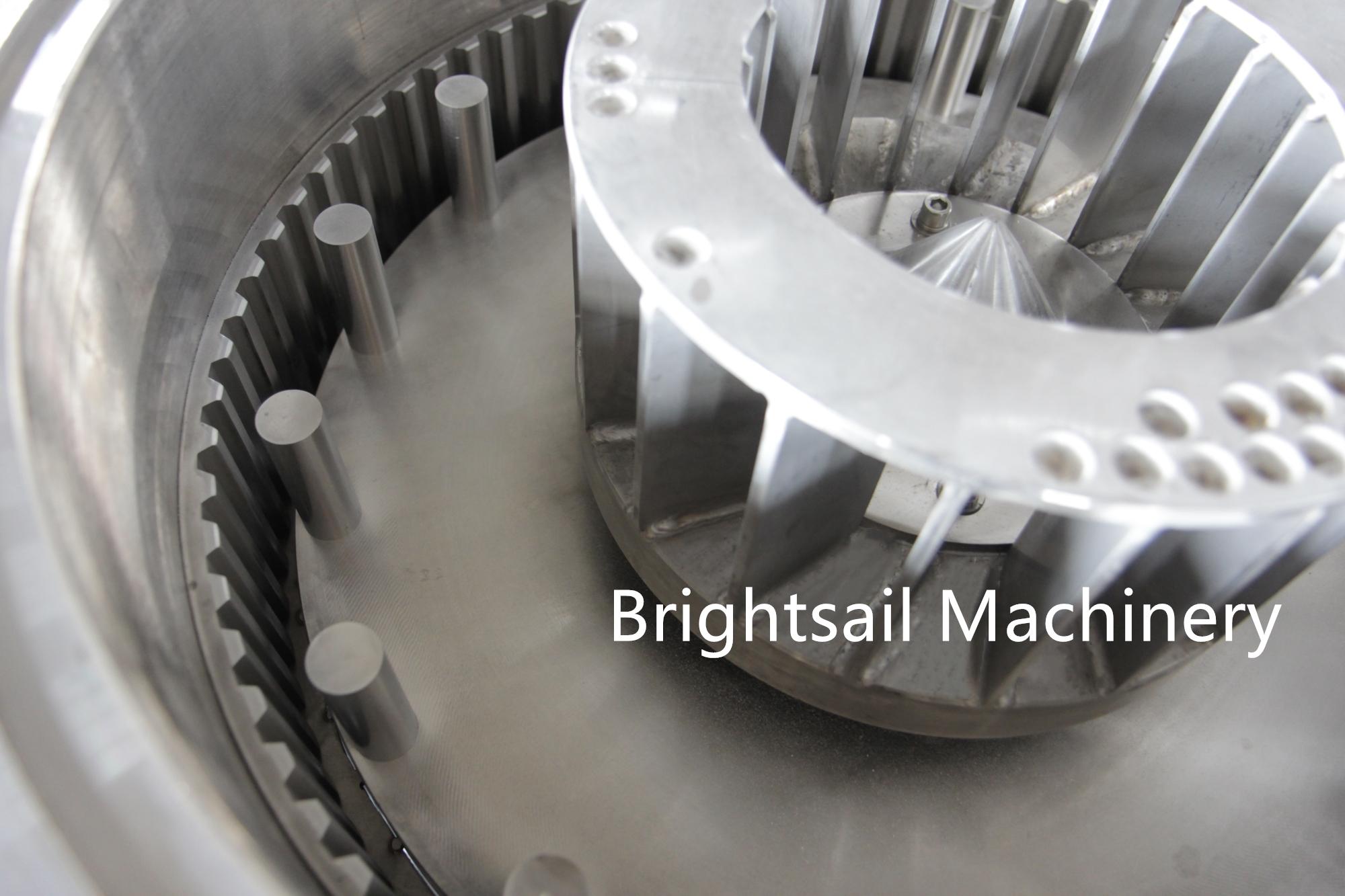

BSP ACM grinder (air classifier mill) is one type grinder which can make very fine powder.

It combines impact milling with integrated dynamic classification is the ideal solution for fine and ultrafine grinding of soft to medium-hard products and is used in all areas of the industry: chemicals, food, pharma, minerals, powder coatings...

Brightsail ACM grinder can make 60~2500 mesh based on different raw material, for example:

For sugar and salt grinding, the output size can be 100~1000 mesh fine powder.

For spice powder like turmeric, ginger and garlic grinding, the output size can be 60~400 mesh fine powder.

For herbal leaf grinding like licorice root, moringa leaf, green tea leaf, the output size can be 60~500 mesh.

For chemical powder grinding like Lithium Stearate, Zinc Stearate, tale, the output size can be 200~10000 mesh based on customer's requests.

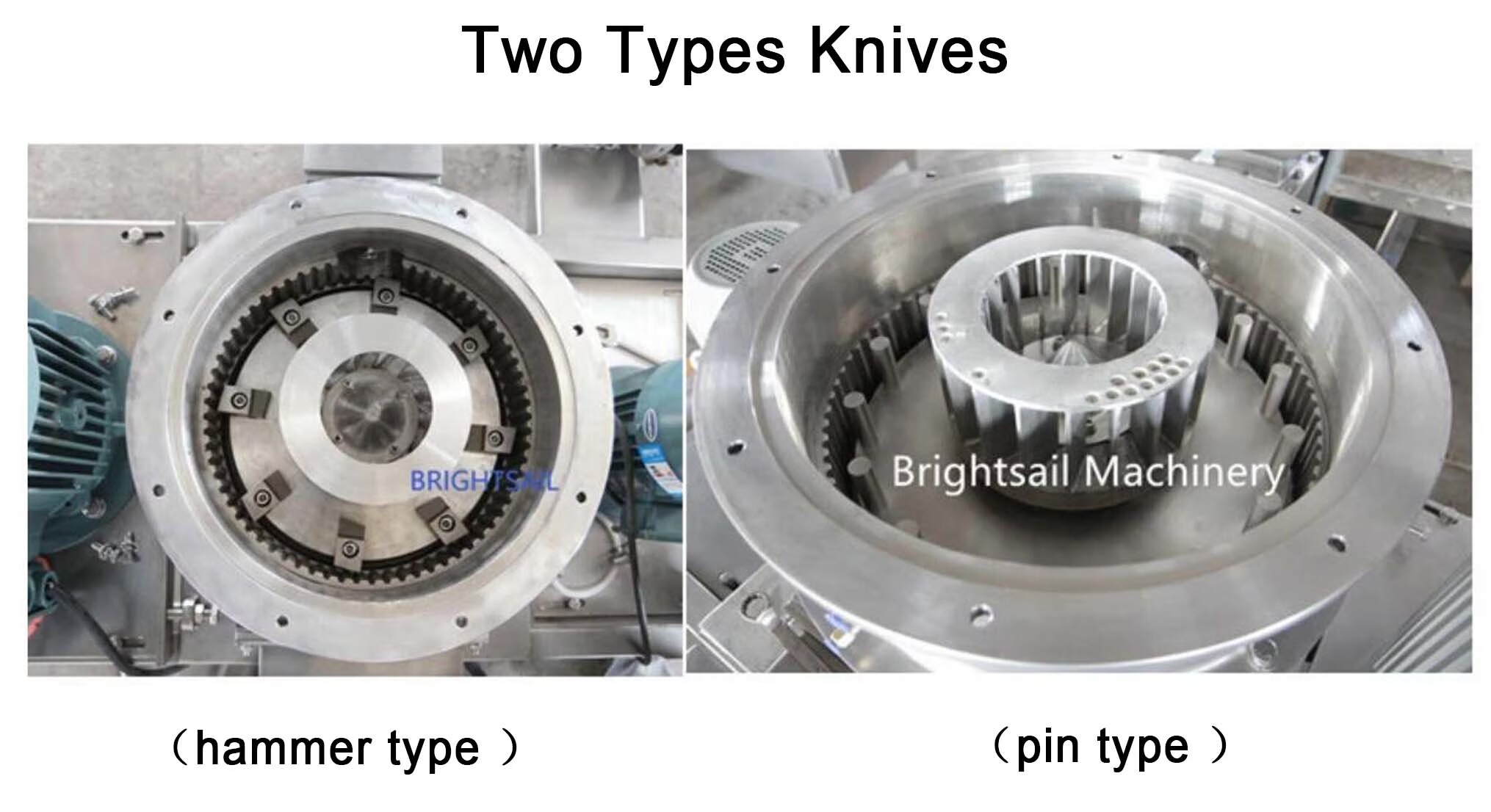

There are two types of knives, hammer type and pin type.Hammer type is standard knife type, which is suitable for various kinds of raw material, spice, chemical, foods, herbs, grains...

Pin type is customized for crystal material grinding like sugar, salt...with high productivity.

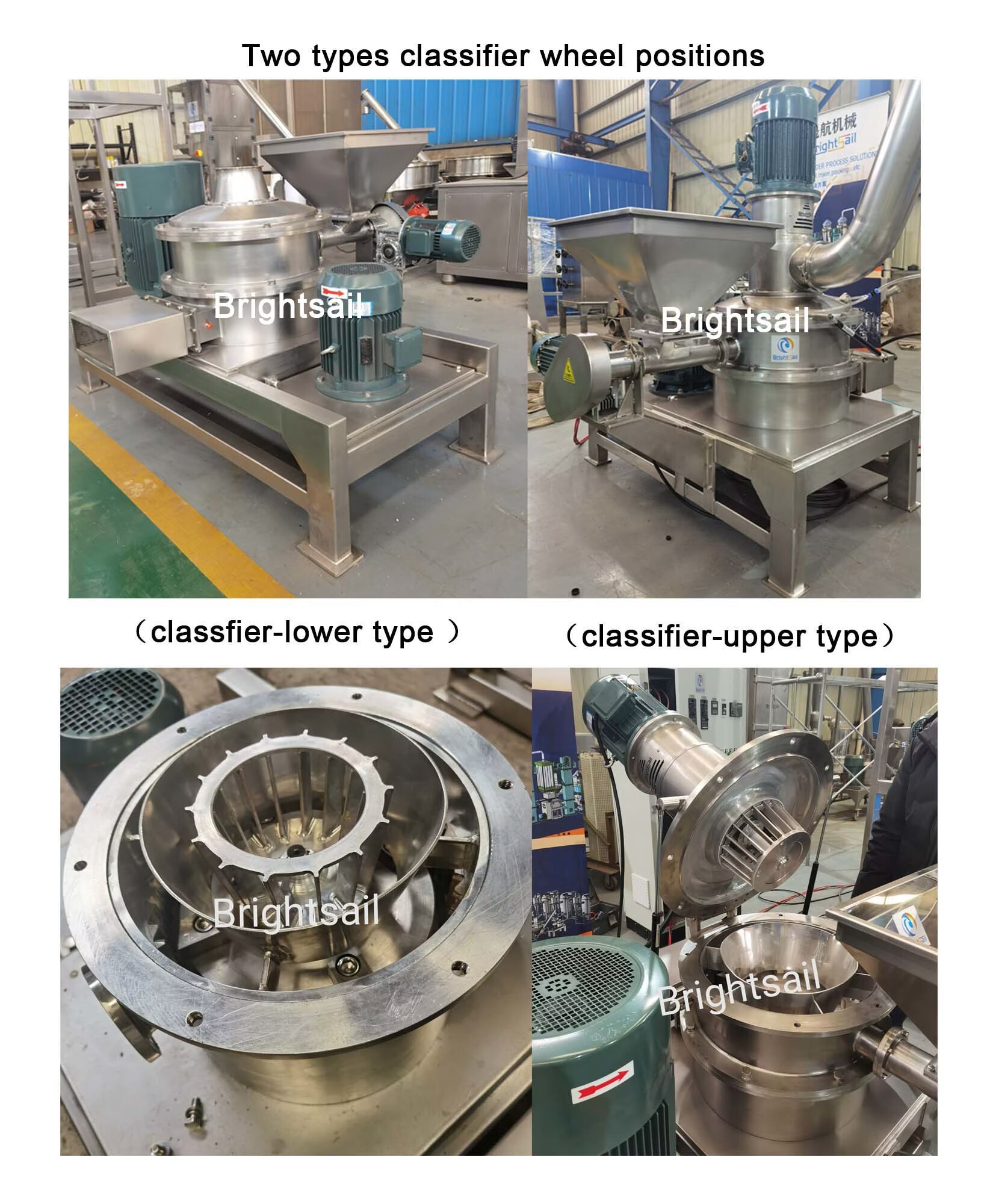

Two types classifier wheel positions:

1) Classifier-lower type: standard type adopts on model BSP-250, BSP-350, BSP-450, and BSP-500.

2) Classifier-upper type: easier cleaning, better stability of mechanical properties and more expensive compared with classifier - lower type.

We recommend the most suitable type based on the characteristic of raw materials, and customers' requirements.

IMPORTANT FEATURES of our Industrial Food Powder Grinder Machine Spice Pulverizer Cinnamon Grinder Machine:

1. By changing the air volume and classifying rotor speed, the particle size can be easily adjusted. This allows the operator

to change product sizes during operation as well.

2. Grinding and Classifying in one machine, Compact footprint 3. Cool and gentle grinding by using water cooling system or equipped with a industrial chiller 4. Steep particle size distributions, Sharp top cut control 5. Easily adjustable cut point, Easy to clean and maintain 6. High availability, Low noise emission, Low specific energy consumption 7. Pressure-shock resistant and wear-protected, Suitable for combined grinding and drying

Technical Data of ACM Pulverizer:

|

Model |

BSP-250 |

BSP-350 |

BSP-450 |

BSP-500 |

BSP-750 |

BSP-900 |

BSP-1000 |

|

Capacity (kg/h) |

10-100 |

20-200 |

40-500 |

50-800 |

120-1800 |

800-2500 |

1000-3600 |

|

Input size (mm) |

< 8 |

< 15 |

< 15 |

< 15 |

< 15 |

<20 |

<20 |

| Powder fineness

(mesh) |

60-2500 |

60-2500 |

60-2500 |

60-2500 |

60-2500 |

60-2500 |

60-2500 |

| Crush motor

(kw) |

5.5 |

15 |

18.5 |

30 |

55 |

90 |

110 |

| Classifier motor

(kw) |

1.5 |

1.5 |

4 |

5.5 |

11 |

15 |

18.5 |

|

Blower (kw) |

4 |

5.5 |

11 |

18.5 |

37 |

45 |

75 |

|

Feed motor (kw) |

0.37 |

0.55 |

0.55 |

1.1 |

1.5 |

2.2 |

2.2 |

| Discharge motor

(kw) |

0.75 |

0.75 |

0.75 |

1.1 |

1.5 |

1.5 |

1.5 |

|

Speed of principle axis (rpm) |

~8400 |

~6500 |

~5600 |

~4400 |

~3100 |

~2450 |

~2450 |

|

Grading impeller speed (rpm) |

~4000 |

~4000 |

~4000 |

~3500 |

~3000 |

~3000 |

~3000 |

Working Principle :

The raw material is charged to the mill chamber via feed screw of hopper, Comminution is the result of particles impacting against the grinding elements of the rotor and against the stationary liner. With high beater tip speeds, fineness values are achieved. The product becomes entrained in the cooling, conveying and classifying airflow generated by the downstream fan, drawn through the mill and routed along the guide vanes of the shroud ring.

The integrated dynamic classifier is characteristic of the ACM grinder. The product/air mixture is distributed uniformly by the guide shroud ring to the rotating classifier. Because of the two opposing forces and the different masses of the particles, the product is separated in the classifying zone into a coarse fraction and a fine fraction. The coarse mate-rial is rejected by the classifying wheel and returned to the grinding zone for further comminution. The fines pass through the cassifying wheel and exit the mill, and then discharge as final products through cyclone part. The cut point, i.e. the product's maximum particle size is a function of the classifying wheel speed, which can be infinitely adjusted even during operation.

And over fine dust is sent to the dust collecting box, to make the full production free from dust.

Member Information

| Brightsail Industries Group Co., Ltd. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 17372871831 |

| Contact: | Charlcey Pu (sales) |

| Last Online: | 31 Mar, 2023 |