Explosion-proof electric ball valve overview:

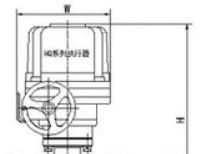

The electric explosion-proof ball valve is mainly composed of an explosion-proof actuator and a ball valve. It is an electric explosion-proof valve used in flammable and explosive conditions. The electrical components on the explosion-proof electric ball valve are required to be fire-proof and anti-static, and all meet the explosion-proof standards. The explosion-proof grade is ExdIIBT4 (CT6), and the protection grade is IP87. The electric explosion-proof ball valve can control the valve switch by inputting the relevant power signal, and can control the operation of the ball valve by inputting the 4-20mA signal and 220/power supply for proportional adjustment, so as to achieve the automatic control of the medium flow, pressure, temperature and other parameters in the pipeline. Applied to explosion-proof occasions such as natural gas, sewage, gas, coal mine, chemical industry, etc. EXDIICT4 grade explosion-proof electric ball valve

Explosion-proof electric ball valve features:

Explosion-proof electric ball valve features:

Explosion-proof Shendong modified valve means that the curved heat actuator of the ball valve h meets the explosion-proof standard. It is used in places requiring explosion-proof, such as liquid or gas (inflammable and explosive places in the chemical industry, used to open and close the valve. Or section, explosion-proof valves can be divided into intrinsically safe type and explosion-proof type. The intrinsically safe type uses a DC motor, and the explosion-proof type uses an AC motor. control, and can also be operated on site.

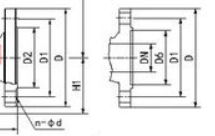

Electric explosion-proof ball valve standard specification:

1. Design and manufacture: GB12237-89, API608, API 6D, JPI7S-48, BS5351, DIN3357.

2. Flange size: JB/T74~90 (JB74~90), GB9112~9131, HGJ44~76, SH3406, ANSI B16.5, JIS B2212~2214, NF E29-211, DIN2543.

3. Structure length: GB12221-89, ANSI B16.10, JIS B2002, NF E29-305, DIN3202.

4. Inspection main test: JB/T9092, API598.

Explosion-proof electric ball valve features:

Explosion-proof electric ball valve features: