Detailed information:

>Ultrasonic cutting machine; Cutting width: 3.2mts

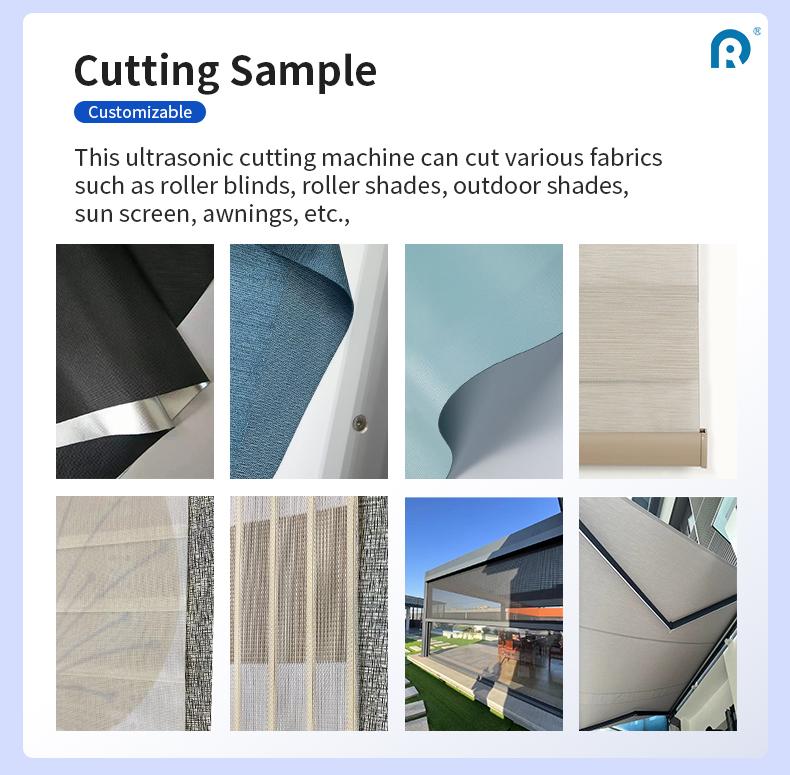

>Machine function: Cutting sunshade fabric into piece;

>Cutting usage: Single layer fabric, like Sunscreen Fabric, Window Blind, Awning, , etc;

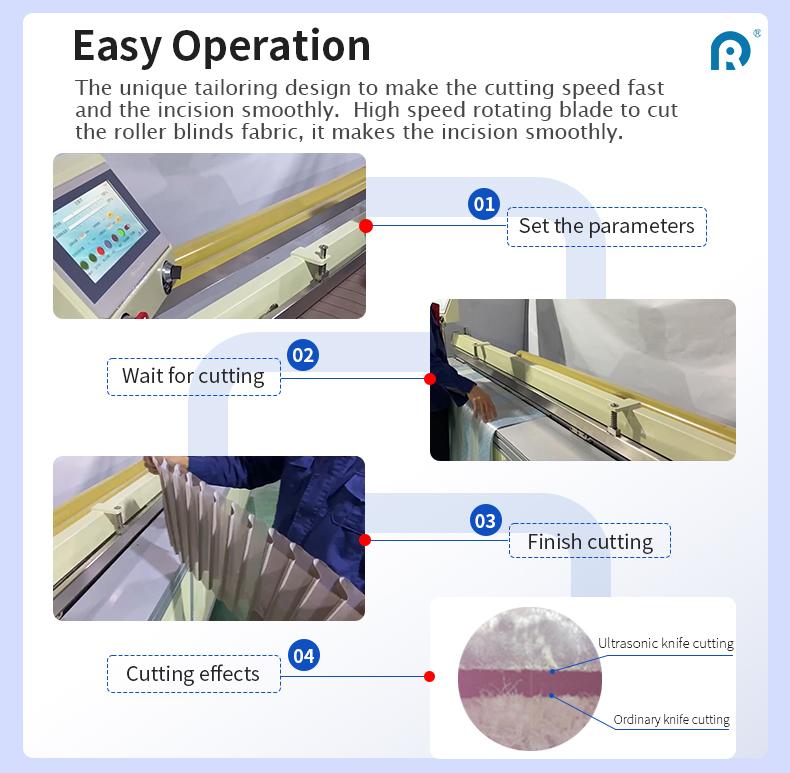

>Technique: Rotary knife with ultrasonic wave, straight cut;

>Automation: Semi-automatic, need a person to operate;

>Advantage: Edge sealing effect for fabric, save labour and time a lot;

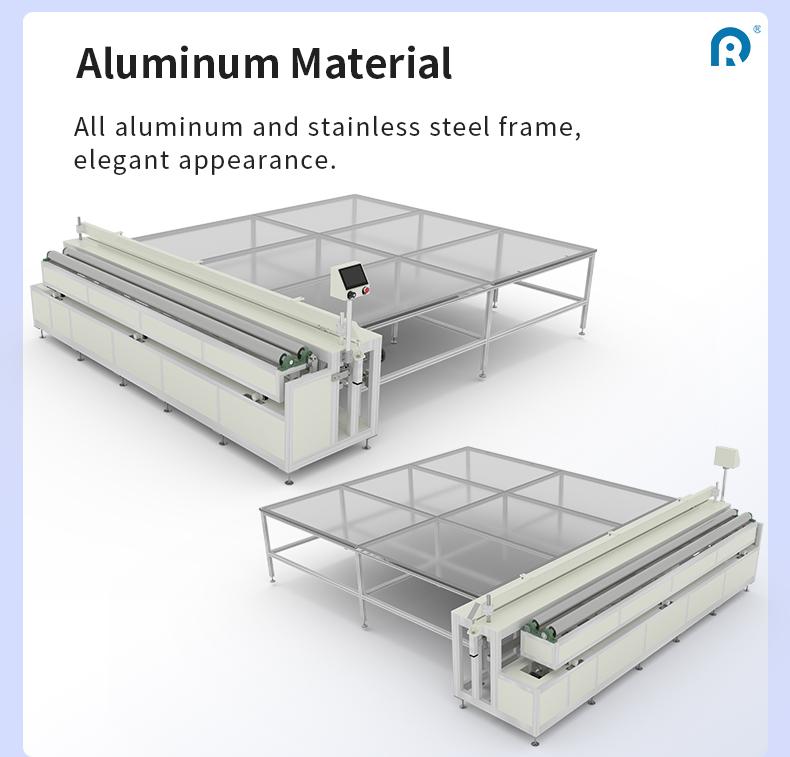

>Characteristics: Precise feeding device, strong aluminum alloy frame, wireless remote control, infrared protection, knife smart return function.

>Warranty: 1 year;

Ancillary equipment:

Glass table(aluminum alloy frame, toughen glass), diameter(Length*Width): 3.2mts*3.2mts, glass thickness: 10mm.

After sale services:

Free warranty period for first year. We supply the parts and maintain on free except non-normal damage; .

All the products sold out enjoy lifelong mechanical maintenance;

After warranty, provides the technical support and the compensated service.

Customers Concerned :

1. Lead time:

> Standard cutting machine: 15 days

> Multifunction cutting machine: 20 days

> Standard welding machine: 15 days

> Multifunction welding machine: 30 days

> Standard slitting machine: 30 days

> Multifunction slitting machine: 40 days

2. Assemble machine:

> Cutting machine: this machine is packed two packages, machine with table in one package, glasses in another package. after receive this machine, please first take out machine and glasses from the wooden package. take aluminum table poles out of the machine. put the machine on the even floor, fix the stands ( 6 stands cup in total), make sure the machine is in horizontal level. after this put the table attachs to machine , put the glasses on the table.

after machine and tables all assembled, need to put the measures on the table, this is to measure the size of the fabrics.

> Welding machine: this machine is packed in one wooden package. take out machine from the package, put it on even floor ,fix the stands cup make sure machine is on horizontal level.

> Slitting machine: this machine is packed in two wooden package. take out machine from the package, put it on even floor ,fix the stands cup make sure machine is on horizontal level. check cables of machine, espcially when connect cables from ultrasonic box to machines.

3. Cutting Machine Table sizes:

> Machine ,tale and glasses can be saled seperately. we s est customers

purchase the glasses in local. It 's not safe to be shipped by ocean.

> standard table sizes: 3.2*3.2 meters ( machine cutting width: 3.2 meters)

or 4.2*4.2 meters ( machine cutting width: 4.2 meters)

or customize any size customers need.

4. Machine Testing:

> we have QC department, after machine is full assembled by production department, QC will test each functions and will report. any problems found while inspection special engineer is going to solve them, then QC test machines again , this is going on and on untill machines are qualified to be ship out.

| Max Fabric Width |

3.2m or customize |

Rated Power |

2.65Kw |

| Fabric Length |

No Limited |

Cutting Speed |

0.5m/second |

| Rated Voltage |

220/110V AC 50/60Hz |

Air Pressure |

0.3-0.5MPa |

| Machine Frame |

Aluminum alloy |

Feed Material |

Semi-automatic |