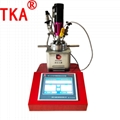

| Model: | HK-25 |

|---|---|

| Brand: | TKA |

| Origin: | Made In China |

| Category: | Chemicals / Chemical Lab Supplies |

| Label: | Teflon Hydrothermal , Synthesis Reactor , Hydrothermal Reactor |

| Price: |

US $57.58

/ pc

|

| Min. Order: | 1 pc |

Product Description

Product Description:

The 25ml hydrothermal synthesis reactor is a closed vessel capable of decomposing insoluble substances and can be used for pre-treatment of dissolved samples in atomic absorption spectroscopy and plasma emission analysis; it can also be used for synthesis reactions in small doses; it can also be used to achieve rapid decomposition of insoluble substances by using the strong acid or base in the tank and the high temperature and pressure closed environment.

The hydrothermal synthesis reactor is used to achieve rapid dissolution of insoluble substances by using a strong acid or base in the tank and a high temperature and high pressure closed environment. It can be used in the determination of heavy metals such as lead, copper, cadmium, zinc, calcium, manganese, iron, mercury, etc. It can also be used as a reaction vessel for high temperature and high pressure corrosion resistance and high purity, as well as for organic synthesis, hydrothermal synthesis, crystal growth or sample ablation and extraction. In sample pre-treatment ablation of heavy metals, sludges, rare earths, aquatic products, organic matter, etc. Therefore, it is widely used in research and production in petrochemical, biomedical, material science, geochemistry, environmental science, food science, commodity inspection and other sectors.

Hydrothermal synthesis reactor product characteristics

1. Good corrosion resistance, no harmful substances overflow, reduce pollution and safe to use.

2. After heating up and pressurising, it can quickly and non-destructively dissolve specimens that are difficult to dissolve under conventional conditions and those containing volatile elements.

3. Beautiful appearance, reasonable structure, simple operation, shorten analysis time and reliable data.

4. With bushing inside, it generates care and can resist acid, alkali, etc.

5. Can replace platinum crucible to solve the problem of dissolved sample processing for trace element analysis in high purity alumina. The high pressure digestion tank used in the oven is a powerful assistant for digesting samples when determining trace elements and trace elements.

Precautions for hydrothermal synthesis reactor

1. when using, it is strictly forbidden to use over temperature and pressure, do not exceed the maximum operating temperature, and the working pressure should not exceed 3MPa.

2. 80% of the capacity of the reaction inner cup. If the reactant produces a lot of gas, it is recommended to cold nitrate overnight, especially with perchloric acid, hydrogen peroxide, etc.!

3. If the experiment is to be carried out in an oven, the necessary safety precautions such as face protection, hand and foot protection, respiratory protection etc. are required when taking the kettle.

Product Parameters

| Products Name | Hydrothermal Synthesis Reactor |

| Working temperature | ≤230ºC |

| Heating and cooling rate | ≤5ºC/min |

| Reaction volume | 10ML/20ml/25ml/50ml/100ml/200ml/500ml |

| Operation Pressure | 3 Mpa |

| Chamber Material | High quality PTFE or PPL. |

| The outer material is high quality stainless steel, the inner material is ptfe. The hydrothermal synthesis reactor is sealed with circular tenon groove, and the sealing effect can be achieved by manual screw to ensure long-term sealing without leakage. | |

The 25ml hydrothermal synthesis reactor has the characteristics of rapid heating, high temperature resistance, corrosion resistance, hygiene, automatic heating without boiler, easy to use and so on. It is a new product successfully developed on the basis of absorbing advanced technology, which is widely used in chemical, food, natural seasoning, food additive, light industry and other industries.

200ml hydrothermal synthesis reactor operation

1. Pour the reaction material into the PTFE bushing and ensure that the filling factor is less than 0.8.

2. Ensure that the lower gasket of the kettle body is correctly positioned (the projection is facing downwards), then put in the PTFE bushing and upper gasket, tighten the kettle lid first, then use the screw to twist and tighten the kettle lid until it is tightened.

3. Place the kettle in the heater and follow the prescribed heating rate to the required reaction temperature. (Less than the specified safe operating temperature).

4. Only open the lid when it is confirmed that the temperature in the belly is below the boiling point of the solvent of the reactant species. When the reaction is finished and the temperature is cooled down, it must also be operated in strict accordance with the prescribed cooling rate in order to facilitate safety and the service life of the reactor.

5. Clean the kettle in time after each use to avoid rust and corrosion. Take extra care to clean the seal of the kettle body and lid, and prevent them from being damaged by bruising.

| Payment Terms: | T/T |

|---|---|

Member Information

| Xi an Mogina Instrument Manufacturing Co. | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 13201558918 |

| Contact: | Amy (Product manager) |

| Last Online: | 26 Jun, 2023 |

Related Products of this Company

-

2000ml Sapphire High Pressure Glass

US $35000

-

Chemical Heating 6 Work Stations

-

Lab Hydrogenation Reactor

US $8189.39

-

Ultrasonic high-pressure photothermal

-

Explosion-proof hydrothermal digestion

-

Magnetic stirring high pressure reactor

US $3303.69

-

Liftable 4000ml High Temperature High

US $11294.12

-

Micro Hydrogenation Reactor

-

Chemical Micro High Pressure Reactor

-

Lab Micro High Pressure Reactor

US $3823.53