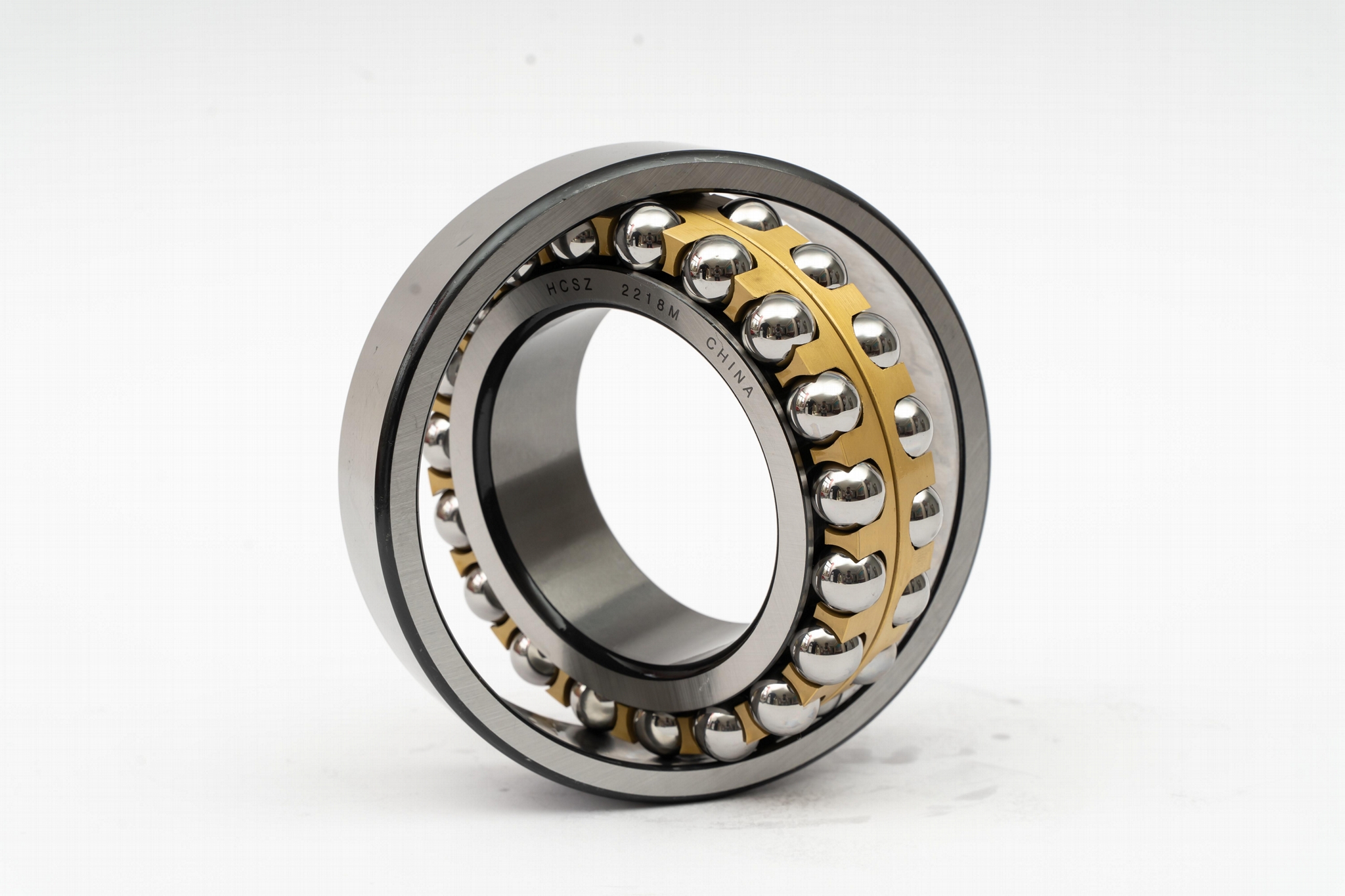

The self-aligning ball bearing is a bearing equipped with spherical balls between the inner ring of two raceways and the outer ring with spherical raceways. The curvature center of the outer ring raceway surface is consistent with the bearing center, so it has the same centering function as the automatic self-aligning ball bearing. When the shaft and housing are flexed, it can be adjusted automatically without increasing the bearing burden.

Self aligning roller bearing can bear radial load and axial load in two directions. Large radial load capacity, suitable for heavy load and impact load. The inner diameter of the inner ring is a tapered bearing, which can be directly installed. Or install it on the cylindrical shaft with a set sleeve and a disassembly cylinder. The cage is made of steel plate pressing cage, polyamide shaped cage and copper alloy car made cage.

The self-aligning ball bearing has two structures: cylindrical hole and conical hole. The cage is made of steel plate, synthetic resin, etc. Its feature is that the outer ring raceway is spherical and has automatic centering, which can compensate the error caused by different concentricity and shaft deflection, but the relative inclination of the inner and outer rings shall not exceed 3 degrees.

It can bear large radial load and certain axial load. The outer ring raceway of this type of bearing is spherical, so it has centering performance. When the shaft is forced to bend or tilt, so that the relative inclination between the inner ring centerline and the outer ring centerline does not exceed 1 °~2.5 °, the bearing can still work.

The inner bore of self-aligning ball bearing is cylindrical and conical. The taper of the conical inner hole is 1:1 2 or 1:30. In order to strengthen the lubricating performance of the bearing, the annular oil groove and three oil holes are machined on the outer ring of the bearing.