| Model: | - |

|---|---|

| Brand: | TOPTITECH |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Heat Exchange & Air Conditioners |

| Label: | corrugated plate , porous metal plate , titanium sheet |

| Price: |

US $20

/ pc

|

| Min. Order: | 3 pc |

Product Description

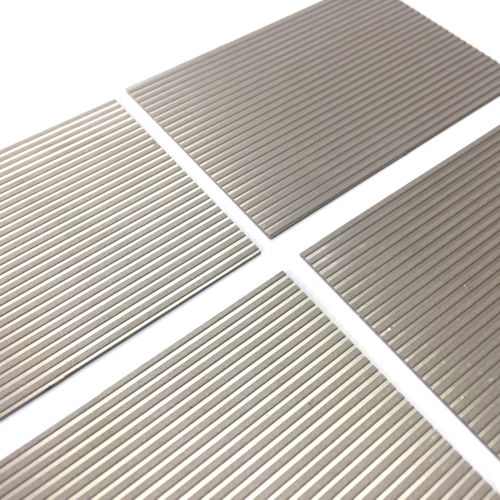

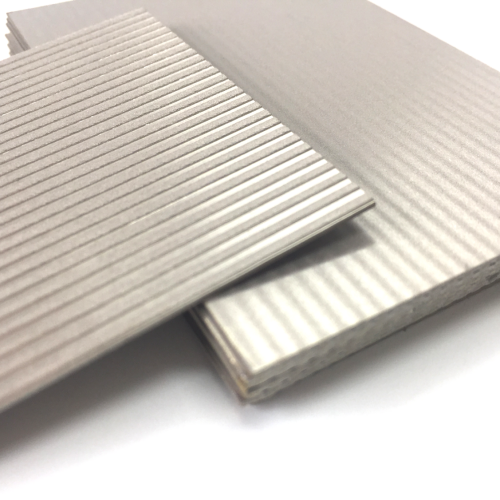

Titanium Powder Corrugated Plate for Heat Exchanger

Titanium powder corrugated plate is a kind of titanium corrugated plate manufactured by titanium powder metallurgy process. Specifically, the titanium powder metallurgy process is to mix titanium powder and other additives, and then process it under high temperature and pressure to form titanium corrugated plates.

Titanium powder corrugated plates are commonly used in heat exchangers, where they help to improve the efficiency of heat transfer between fluids by increasing the contact area between the fluids and the plate surface. They are also used in the chemical and petrochemical industries, as well as in the aerospace and marine industries, due to their resistance to corrosion and high strength-to-weight ratio.

Parameter

Material: pure titanium, Ti-6Al-4V,Ti-3Al-2.5V

Length: Max. 1000mm

Width: Max.600mm

Thickness: Max. 50mm

Pore size: 0.2-60um

Wave height: 0.2mm,0.3mm or customized

Wave width: 1.2mm,1.3mm or customized

Wave pitch: 0.7mm,0.8mm or customized

The main steps for manufacturing titanium corrugated plate using titanium powder metallurgy process include:

Titanium powder preparation: First, the titanium powder needs to be prepared into appropriate particle size and shape for further processing.

Additive mixing: Mix the titanium powder with other additives such as copper, aluminum, etc. to improve the workability and mechanical properties of the titanium powder.

Pressing and forming: Put the mixed titanium powder and additives into a mold for pressing and forming. This process needs to be carried out under high pressure, usually between 100MPa to 2000MPa.

Sintering: Sinter the pressed and formed titanium powder at high temperature to make it into an integrated titanium corrugated sheet. This process needs to be carried out in an inert atmosphere to avoid oxidation.

Heat treatment and surface treatment: After sintering, the titanium powder corrugated sheet needs to undergo heat treatment and surface treatment to improve its mechanical and corrosion resistance properties.

Compared with the traditional titanium plate rolling process, the titanium powder metallurgy process can manufacture titanium corrugated sheets with more complex shapes and structures. In addition, the titanium powder metallurgy process can also control the pore size, wall thickness, wave height, and wavelength of the titanium corrugated sheet to meet different filtration requirements.

Features

1. Stability under high temperature and high pressure: Titanium powder corrugated sheet can maintain stability and strength under high temperature and high pressure, and can therefore be used for filtration and separation in harsh environments such as high temperature, high pressure, and strong corrosion.

2. High filtration efficiency: The corrugated structure of titanium powder corrugated sheet can increase its surface area, thereby improving its filtration efficiency and capture capacity, especially suitable for applications that require high-efficiency filtration and separation.

3. Good mechanical properties: Titanium powder corrugated sheet has high strength, high hardness, and good ductility, and can withstand large mechanical stress and deformation.

4. Good corrosion resistance: Due to the use of titanium powder metallurgy process in the manufacture of titanium powder corrugated sheet, its material composition and structure can be controlled, thereby improving its corrosion resistance.

5. Easy to clean and maintain: The corrugated structure of titanium powder corrugated sheet can increase its surface area, making it easy to clean and maintain, reducing maintenance costs and time.

Application

1. Energy industry: Titanium powder corrugated plates can be used in the energy industry for various applications such as heat exchangers in power plants, desalination plants, and oil refineries. Their high conductivity and thermal stability make them ideal for use in high-temperature applications.

2. Aerospace industry: Titanium powder corrugated plates can be used in the aerospace industry for various applications such as heat exchangers, fuel cells, and cryogenic storage tanks. Their high strength-to-weight ratio and resistance to corrosion make them ideal for use in harsh environments.

3. Water treatment: Titanium powder corrugated plates can be used in water treatment industry for filtration, purification, and desalination processes. For example, they can be used in seawater desalination plants to remove impurities and salt ions.

4. Chemical industry: Titanium powder corrugated plates can be used in chemical industry for filtration, separation, dehydration and drying processes. In chemical reactions, titanium corrugated plates are not corroded or polluted, which can improve reaction efficiency and product purity.

5. Biomedical industry: Titanium powder corrugated plates can be used in biomedical industry for separation, filtration, concentration and purification processes. Their high efficiency of filtration and separation can improve production efficiency and product quality.

6. Food and beverage industry: Titanium powder corrugated plates can be used in food and beverage industry for filtration and separation processes. For example, they can be used for clarification of beer, wine, fruit juice, and tea.

Member Information

| TOPTITECH(Baoji Yinggao Metal Materials Co., Ltd.) | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 19909178529 |

| Contact: | Lisa Yue (sales manager) |

| Last Online: | 28 Dec, 2024 |