| Model: | - |

|---|---|

| Brand: | TOPTITECH |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Products |

| Label: | titanium plate , corrugated plate , porous metal plate |

| Price: |

US $13.56

/ pc

|

| Min. Order: | 3 pc |

Product Description

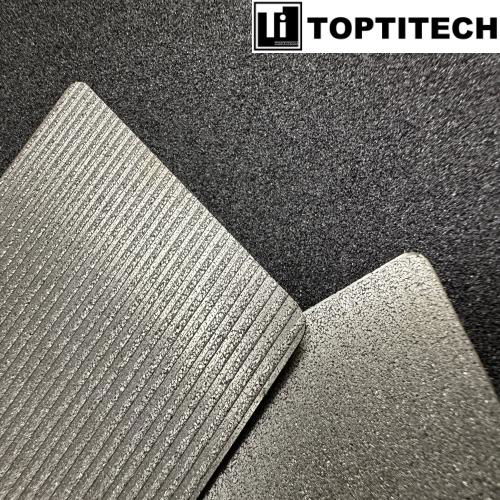

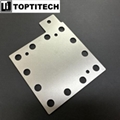

Titanium Micro Porous Flow Channel Plates

Titanium micro porous flow channel plates are widely used materials made from titanium powder using sintering processes. They consist of numerous tiny pores that provide channels and distribution paths for fluid or gas transfer. Titanium porous flow plates find extensive applications in various industrial sectors such as chemical engineering, oil and gas industry, aerospace, and more.

The porous structure of titanium micro porous flow channel plates offer additional pathways and opportunities for fluid or gas transfer and dispersion. It enhances mass transfer, heat transfer, and mixing effects, while also allowing for control of flow rate and pressure drop according to specific needs. These characteristics make titanium porous flow plates crucial in various applications, including chemical reactions, sensors, filtration, and separation processes.

Parameters

Material:pure titanium

Brand:TOPTITECH

Technical:sintering

Size:60*60*1mm

Chamfer:as drawing

Pore size:30 microns

Features

Enhanced mass transfer and heat transfer: The porous structure of titanium flow plates provides numerous channels and pathways for fluid or gas flow. This increases the contact surface area between the flow medium and the flow plate, promoting efficient mass transfer and heat transfer processes. The enhanced interfacial contact leads to improved performance in applications such as chemical reactions, filtration, and heat exchangers.

Tailorable pore structure: The pore structure of titanium porous flow plates can be customized and tailored to specific application requirements. The shape, size, distribution, and porosity of the pores can be engineered to achieve desired flow characteristics, pressure drops, and flow rates. This flexibility allows for optimized design and performance in various applications.

Thermal conductivity: Titanium possesses good thermal conductivity, enabling efficient heat transfer and distribution across the flow plates. This property is particularly beneficial in applications that require precise temperature control, such as fuel cells, where uniform heat distribution is crucial for optimal performance.

Versatile applications: Titanium porous flow plates find applications in a wide range of industries and technologies. Some notable areas include chemical engineering, oil and gas industry, aerospace, biomedical engineering, renewable energy, and more. They are used in reactors, separators, fuel cells, heat exchangers, sensors, and other systems where fluid or gas handling, mass transfer, and heat management are essential.

Applications

Chemical Engineering: Used in chemical reactors, adsorption separation, catalyst carriers, etc., to provide uniform mass transfer and reaction effects.

Oil and Gas Industry: Used in oil well production, gas separation, corrosion protection, etc., to meet complex process requirements and environmental conditions.

Aerospace: Used in aerospace engines, fuel cells, spacecraft thermal control, etc., to provide efficient fluid and thermal management.

Biomedical: Used in artificial organs, tissue engineering, drug delivery, etc., to achieve precise substance transport and biological reactions.

Renewable Energy: Titanium porous flow plates can be used in fuel cells, solar cells, etc., to provide efficient gas and electron transfer.

How does the porous structure of titanium porous flow plates affect the transfer and dispersion of fluids and gases?

Channeling and Distribution: The porous structure creates numerous tiny pores, providing channels and distribution paths for fluids or gases. These channels allow for the uniform transfer of fluids or gases within the flow plate and dispersion into a broader area.

Increased Contact Surface Area: The presence of a porous structure increases the contact surface area between the fluid or gas and the flow plate. This enhances mass transfer and heat transfer processes, allowing for more thorough interaction between the fluid or gas and the flow plate.

Promotion of Turbulence and Mixing: The porous structure can induce turbulence and mixing effects in fluids or gases. Due to the presence of pores, fluids or gases passing through the porous flow plate generate turbulence and vortices, increasing the degree of mixing and improving mass transfer and heat transfer efficiency.

Control of Flow Rate and Pressure Drop: The porous structure can control the flow rate and pressure drop of fluids or gases through the shape, size, and distribution of the pores. Different pore structures can achieve different flow rate distributions and pressure gradients, meeting the fluid or gas transfer requirements in specific applications.

Member Information

| TOPTITECH(Baoji Yinggao Metal Materials Co., Ltd.) | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 19909178529 |

| Contact: | Lisa Yue (sales manager) |

| Last Online: | 26 Oct, 2024 |

Related Products of this Company

-

100*100*0.5mm Thick Titanium Foil

US $20

-

0.4mm Ti felt for LGDL in PEM

US $6

-

70% Porosity Titanium Fiber Paper Felt

US $3.21

-

Customized GR1 Titanium Anode Plate for

US $28.56

-

Gr5 Titanium Scrap Turnings for Ferro

US $5.2