| Model: | PSA Oxygen |

|---|---|

| Brand: | WellCare |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | Oxygen Generator , Medical Oxygen Produ , Oxygen Production Pl |

| Price: |

US $15000

/ Set

|

| Min. Order: | 1 Set |

Product Description

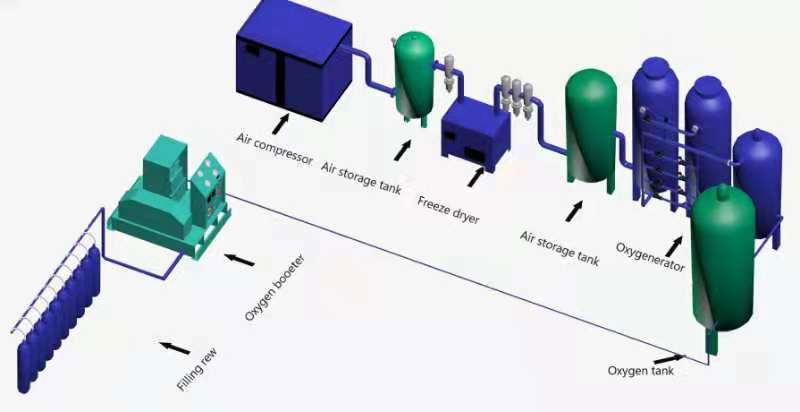

Oxygen filling (or booster) with liquid pump.

The Plant uses normal temperature molecular sieve adsorption, medium pressure booster expansion reflux flow.

Raw air is sucked from the atmosphere,It is going through filter for removal of dust and mechanical impurities.,then it is compressed to a certain degree by single stage screw compressor,via end stage cooler, air pre-cooling system, the air is cooled to approx. 8ºC. After water separation moisture is separated in water separator and then it goes to purifier for removal of moisture, CO2, C2H2 and hydrogen dioxide.

Then most part of air enters main heat exchanger to be cooled to saturated tempt. and partly is liquefied to the lower part of lower column; another part of air is compressed to a certain degree through two stage compression booster, via end stage cooler enters into oxygen heat exchanger to be cooled to be near saturated temperature, then after throttle goes to lower column. Through lower column pre-distillation we can get enriched oxygen liquid air from the bottom of the column. After cooling through sub-cooler,after throttled it goes to the middle part of upper column as reflux liquid for rectification. WN is obtained from the top of lower column, after condensed through condenser-evaporator, a part of WN is used as rectification reflux liquid for lower column; another part after cooling through sub-cooler and after throttling goes to the top of upper column as rectification reflux liquid. Pure liquid oxygen is obtained from the bottom of upper column, and it is condensed by condenser-evaporator. Liquid oxygen is abstracted from the bottom after cooling through sub-cooler, then it goes to LOX pump to be pressurized. It is evaporated in O2 heat exchanger and is reheated to normal tempt and then directly goes to oxygen filling ramp for filling of cylinders.

WN from the top of upper column goes through sub-cooler, the ower part of main heat exchanger to be reheated to a certain tempt. Then it goes to expansion turbine to create cold and returns to sub-cooler and main heat exchanger again to be reheated to normal tempt. A part of it passes to purifier as regenerating gas resource and another part goes to be vented partly.

The main technical specifications of external compression

| Model contents |

KDON- 80/200 |

KDON- 180/500 |

KDON- 350/800 |

KDON- 550-1000 |

KDON- 750-1500 |

KDON- 1000-2000 |

KDON- 1500-3000 |

KDON- 3000-3000 |

|

| Gox flow | Nm³/h | 80 | 180 | 350 | 550 | 750 | 1000 | 1500 | 3000 |

| Gox purity | %(O2) | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 |

| Gan flow | Nm³/h | 200 | 500 | 800 | 1000 | 1500 | 2000 | 3000 | 3000 |

| Gan purity | Ppm(O2) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

|

Operating pressure |

Mpa | 0.65 | 0.63 | 0.62 | 0.6 | 0.58 | 0.58 | 0.56 | 0.56 |

| Start-up time | hour | ≤12 | ≤14 | ≤16 | ≤16 | ≤18 | ≤18 | ≤20 | ≤20 |

|

Operating period |

year | ≥1 | ≥1 | ≥1 | ≥1 | ≥1 | ≥2 | ≥2 | ≥2 |

| Payment Terms: | TT / LC / DP / DA |

|---|---|

Member Information

| zhejiang wellcare technology co., ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 18766361779 |

| Contact: | david liu (sales manager) |

| Last Online: | 06 Sep, 2023 |

Related Products of this Company

-

Psa Plant Liquid Nitrogen Generator

US $18000

-

natural gas hydrogen production

US $35000

-

High Purity Industrial Liquid Nitrogen

US $3000