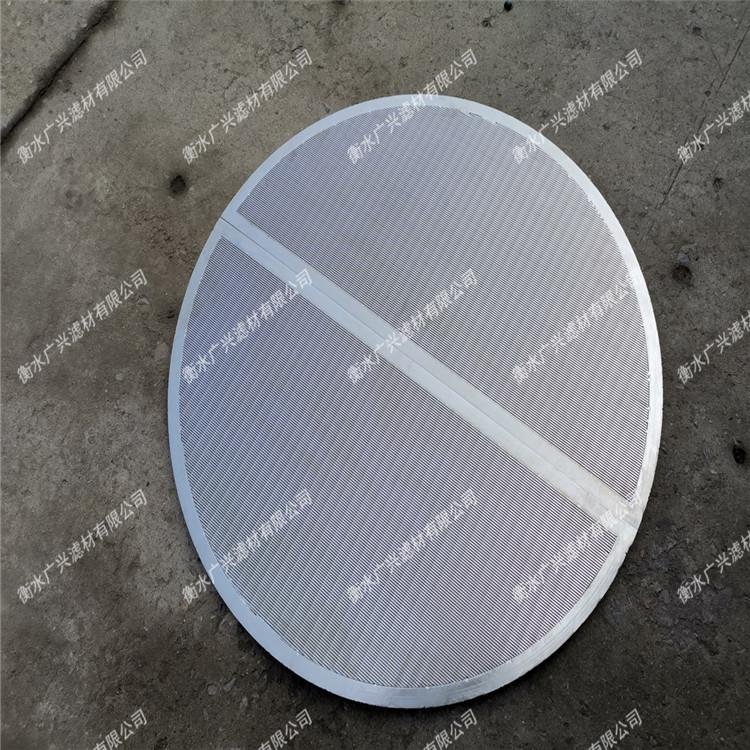

Hengshui Guangxing Filter Material Co., Ltd. introduces advanced foreign technology and specialized tooling equipment, with a systematic process flow and strict quality assurance system to ensure the cost-effectiveness of the products. We can produce different widths, lengths, seam widths, and wedge wire sizes of sieve plates according to your filtration requirements and filtration materials. We can also add sieve plates according to your requirements, which are easy to leak, wear-resistant, and corrosion-resistant. The cross-section is trapezoidal, with narrow gaps above and wide gaps below. The screen seam is uniform, the welding quality is stable, the opening rate is high, the service life is long, and it has high strength, stiffness, and load-bearing capacity. It can be made into various shapes of rigid screening and filtering devices

Gap (mm): 0.10, 0.15, 0.2, 0.25, 0.30-3, can be made according to customer requirements.

Material: low-carbon steel, galvanized low-carbon steel, plastic spraying, stainless steel (304316, etc.)

Function and characteristics:

1 Detachable structure for easy assembly.

2 Good wear resistance and long service life.

3 Good moisture resistance and wear resistance.

4 Automatic cleaning, high screening efficiency. Widely used in industries such as mining, coal, petroleum, fertilizers, grain, salt, environmental protection, etc., screening materials such as liquids and powders, petroleum, chemical, metallurgical, mining, pharmaceutical purification, filtration tanks, water treatment equipment, drilling fluid purification, etc. We can process and produce various shapes and required sieve plates according to user needs.