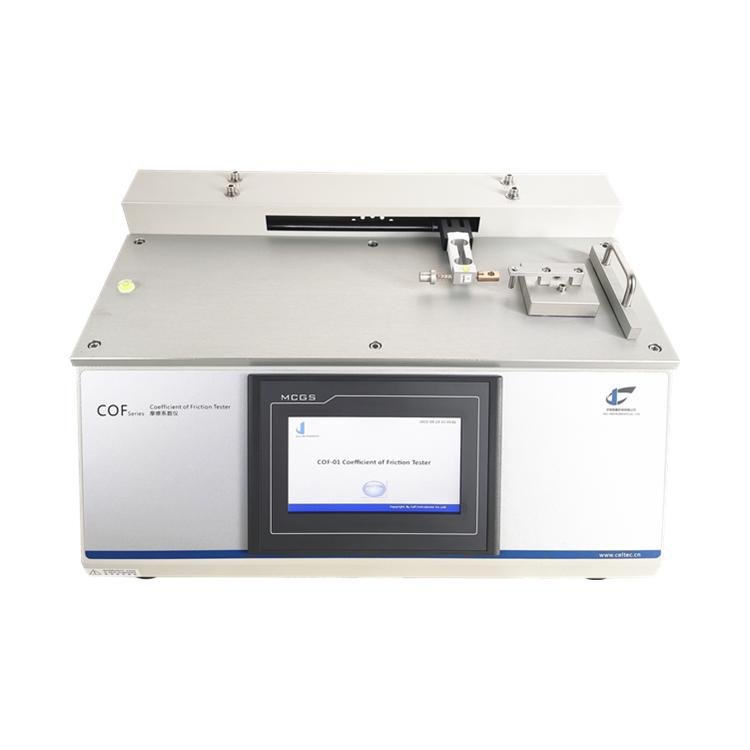

| Model: | COF-01 |

|---|---|

| Brand: | Cell Instruments |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Electronic Instrument / Other Electronic Instrument |

| Label: | coefficient friction , friction , paper/film friction |

| Price: |

US $3000

/ set

|

| Min. Order: | 1 set |

Product Description

Background

The coefficient of friction pertains to the friction present between two surfaces. A lower coefficient of friction signifies that less force is needed for sliding to commence, while a higher value indicates a greater force requirement.

The coefficient of friction varies based on the specific materials involved. In the context of packaging film, the coefficient of friction refers to the extent of 'slipperiness' exhibited by the packaging material when in contact with different components of the packaging machine or other materials.

The management of the coefficient of friction holds significance in enhancing performance and mitigating issues during the creation, transportation, and storage of packages.

Numerous factors, such as antiblock additives, corona treatment, antistatic agents, inks, varnishes, and adhesives, can influence the coefficient of friction.

Application

The COF-01 Coefficient of Friction Tester is designed to measure both static and kinetic coefficients of friction for a wide range of materials. These materials include plastic films, sheets, rubber, paper, paperboard, woven and non-woven fabrics, metal-plastic composite belts used in communication cables and conveyor belts, wood, coatings, brake pads, windshield wipers, shoe materials, and tires. The tester can also be adapted or modified to accommodate various other material types and testing standards.

Standards

ASTM D1894, ISO 8295, TAPPI T816, GB 10006

Formula

The coefficient of friction (COF) is calculated by dividing the force needed to move one surface across another by the force perpendicular to the surfaces. The formula is μ = f ÷ N, where μ represents the coefficient of friction, f is the force of friction, and N is the normal force. There are two types of coefficients of friction: static and kinetic.

Static COF (μs): The static coefficient of friction (μs) quantifies the force required to initiate movement between two surfaces. In the packaging industry, the static coefficient of friction is commonly used to assess the friction between bags during stacking, cartoning, or palletization, especially when plastic surfaces come into contact with each other.

Kinetic COF (μd): The kinetic coefficient of friction (μd) measures the force necessary to sustain ongoing movement between surfaces. In the packaging sector, the kinetic coefficient of friction finds application in scenarios involving rolls of plastic films processed on packaging machinery. This is particularly relevant for situations where plastic surfaces interact with metal components.

Technical Features

The COF-01 Coefficient of Friction Tester has been aiding the flexible industry since its inception.

1.It employs PLC control and an HMI touch screen for interaction. The design, of industrial caliber, assures stability and extended service life.

2.The driving mechanism is powered by a stepper motor and a precision ball lead screw.

3.It exhibits real-time test curves, and automatically records maximum, minimum, and average test results.

4.Both static and kinetic coefficients of friction are gauged.

5.Compliance with multiple test standards is incorporated.

6.A dot matrix microprinter is integrated.

7.The test plane is constructed entirely from aluminum.

8.It offers RS232 output and professional software(Optional).

9.Local language display is supported(Customized).

Main Parameters

Load Cell 5 N(or as required)

Accuracy 0.5 F.S.

Sled 200±1g (or as required)

Sled Size 63.5mm*63.5mm (or as required)

Test Speed 100mm/min (ISO), 150mm/min (ASTM)

Dimensions 540mm(L)*380mm(W)*240mm(H)

Weight NW 21kg

Power 110~220V 50/60Hz

Member Information

| Cell Instruments | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 60733670 |

| Contact: | Yvette Yang (Sales) |

| Last Online: | 19 Oct, 2023 |

Related Products of this Company

-

Flex Durability Tester

US $5000

-

Leak Tester

US $2000

-

Film Free Shrink Tester

US $3000

-

Falling Dart Impact Tester

US $3000