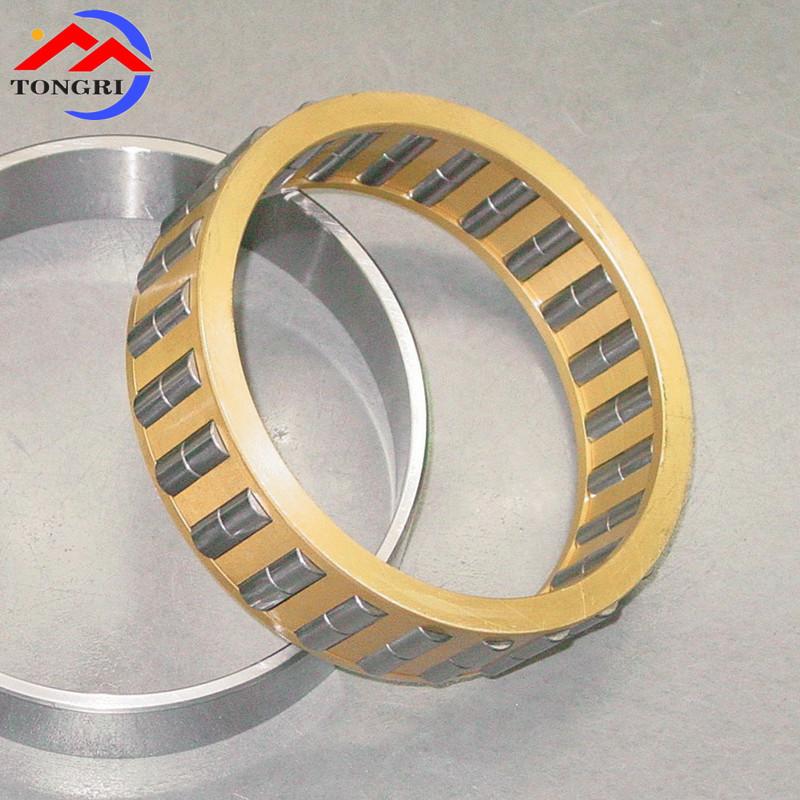

With cylindrical rollers which are thin and long in relation to their diameter

They are referred to as needle rollers, in spite of their low cross section the bearings have a high load carrying capacity and are thus extremely suitable for bearing arrangements where radial space is limited

Needle roller bearings have a high load carrying capacity in addition to their low cross-section and stiffness

Suitable for bearing arrangements where radial space is limited

Because needle roller bearings only carry pure radial load and can not limit the axial displacement of shaft relative to the housing

It is important to ensure that inner ring axis and outer ring axis must be aligned during mounting the bearings

Heavy-duty needle bearings have a heavy outer ring made from materials, load capacity is higher

There is a problem of slippage between the roller and raceway surfaces, which occurs because the rollers are cylindrical rather than tapered

Typical applications: Gear pumps, sheaves and automotive transmissions