Features of HM-1812-16 CNC deep hole drilling machine tool:

1. The casting of the CNC deep hole drilling machine tool is made of high-quality cast iron and has undergone aging treatment to ensure uniform and stable casting structure, high rigidity, and good stability.

2. The three-axis screw rod of the CNC deep hole drilling machine tool adopts imported Taiwan PMI high rigidity and precision screw rods, which provide stronger torque during processing and are more durable.

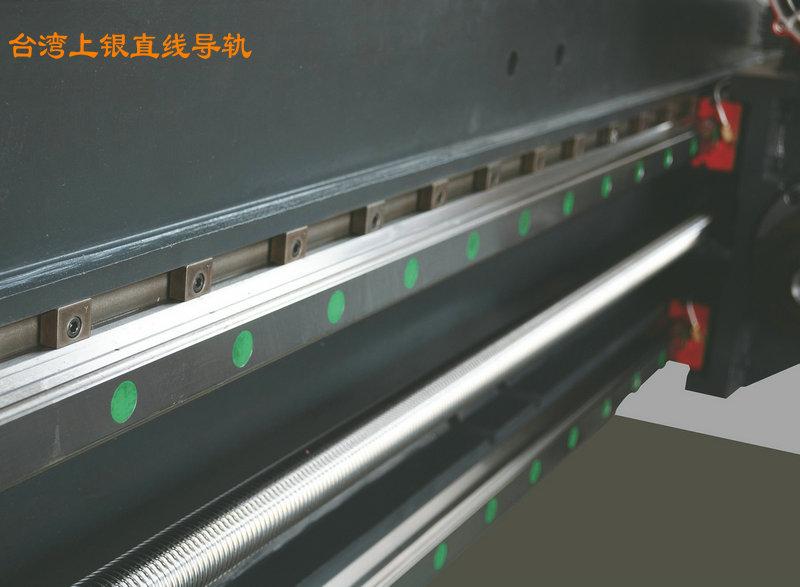

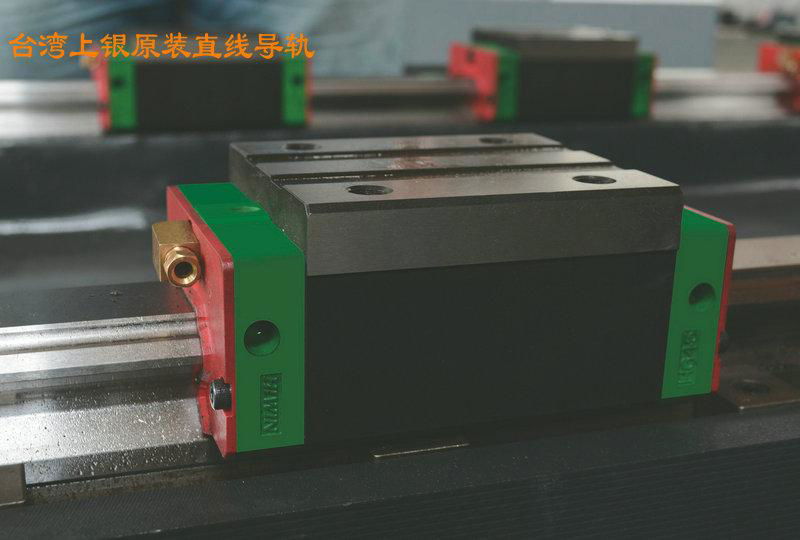

3. The three-axis linear guide rail of the CNC deep hole drilling machine adopts imported Taiwan Shangyin high rigidity, heavy load, high speed, and high precision ball linear guide rail, ensuring high machining accuracy and extending the service life of the linear guide rail.

4. The three-axis feed drive of the CNC deep hole drilling machine tool adopts well-known brand servo motors and drivers, and is directly connected to the ball screw, with smooth transmission and no backlash. At the same time, its good rigidity and optimized shock absorption performance greatly improve the dynamic rigidity of the transmission system, enabling fast movement.

5. The spindle motor of the CNC deep hole drilling machine tool adopts a powerful servo motor, which can meet the processing needs of high and low speeds, and is equipped with an automatic oil cooling system to ensure constant temperature during processing.

6. The operating system of the CNC deep hole drilling machine tool adopts the new generation system from Taiwan, which is compatible with CAD/CAM software and can be used with more elements.

The processing range of Guangdong Harman CNC deep hole drill:

Suitable for deep hole processing of various types of workpieces: plastic molds (including water holes and hot runners); Automotive parts; Crankshaft connecting rods, hydraulic pipelines, etc. With the rapid development of the mainland automotive and home appliance industries, and the rapid demand for large molds, deep hole machining machines have saved customers a lot of processing time. In the past, small and medium-sized manufacturers only changed old machine tools for deep hole machining, but efficiency and accuracy are difficult to guarantee. Other manufacturers will rely on large processing plants or raw material suppliers for processing, in addition to time being difficult to control, Transportation often affects progress, so since its launch, deep hole machining machines have not only been purchased by mold factories and large processing factories, but also received inquiries from many small and medium-sized mold factories, which is sufficient to prove the market demand for this product.

HM-1812-16 CNC Deep Hole Drilling Machine Tool Parameter Table

Sequence Number Item Content

1. Drilling diameter (mm) φ 3~ φ 40mm

2. Drilling depth (mm) 1600mm

3. Workbench bearing capacity (T) 12

4. Workbench size (mm) 2000mm * 1200mm

5. Spindle power (KW) 11/15

6. Net weight of machine tool (T) 12

7. Spindle motor power (KW) 11/15

8. Spindle variable frequency power (KW) 11/15

9. Tool feed speed range (stepless) 0-300mm/min (non limiting parameter)

10. Machine tool peripheral dimensions (mm) (length * width * height) 5300mm * 4800mm * 2800mm

11. Spindle speed range (stepless) 0-6000 r/min

12. Three axis servo power (KW) X axis: 3.0 Y axis: 3.0 Z axis: 2.0