| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Agriculture & Foods / Processed Food / Snacks |

| Label: | - |

| Price: |

-

|

| Min. Order: | - |

Product Description

Products Description:

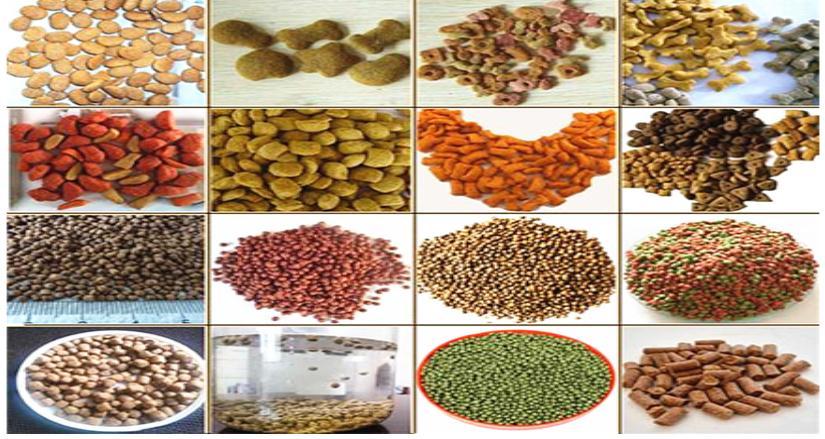

Custom pet food machinery is an innovative product that provides pet owners with the convenience of creating personalized meals for their furry friends. This product is designed to produce high-quality, customized pet food that meets the unique nutritional needs of each pet. The machinery includes a set of automated tools that can be programmed to process different ingredients, mix them in precise proportions, and cook them to perfection.

One of the key benefits of this device is the ability to tailor the ingredients to meet the specific needs of each animal. This allows pet owners to control the quality and nutritional value of the food, ensuring that their pets receive a healthy and balanced diet that supports their overall health and well-being.

The versatility of this machinery is another advantage. It can be used to create various types of pet food, such as dry kibble, canned food, and frozen meals. This flexibility allows pet owners to create a diverse range of meals that their pets will enjoy.

In addition to convenience and customization, the machinery is also cost-effective in the long run. By creating their own pet food, owners can save money while ensuring that their pets eat high-quality foods that meet their unique needs.

Overall, Custom pet food machinery is an excellent solution for pet owners who want to ensure that their pets receive the best care possible. It provides a convenient, customizable, and cost-effective way to create nutritious meals for pets of all ages and sizes.

Flow Chart Of Custom Pet Food Machinery:

Equipment Details:

Mixer

This equipment mainly using for mixing raw material,water and addictives, raw material mixed fast and evenly.

Power:4.5kw

Volume:50L

Rotate speed:360r/min

Material :stainless steel

Screw Conveyor

The main function of the machine is to transfer the mixed raw materials from the mixer to the feeding system of the single screwextruder.

Power: 0.75kw

Capacity:500kg/hour

Dimension:1600*300*2300mm

Quantity:1PC

Single Screw Extruder

The main functions of extruder are extrusion and material puffing. This automatic extruder is easy to operate and with solid performance for long term.

|

Model |

MD3000-100 |

MD2000-100 |

|

Installed Power |

45KW |

52.5KW |

|

Actual Consumption |

28KW |

35KW |

|

Main Power |

30KW |

30KW |

|

Throughput |

80-100kg/h |

80-100kg/h |

|

Dimension |

3.5*1.05*1.96m |

3.2*1.5*2.0m |

Cooling Conveyor

A cooling conveyor is a conveying system that transports products from a single screw extruder to a cutting machine while also cooling or preventing overheating.

Power:1.4kw

Material:stainless steel

Mesh belt width: 600mm

Cutting Machine

Cut and shape the cooled food according to the predetermined size and size

Power:1.5kw

Cutting capacity:150kg/h

Material:stainless steel

Hoist

The cut molding product is transferred to the dryer.

Power: 0.75kw

Capacity:≥500kg/h

Dimension : 2000*400*2500mm

Dryer

It includes a transmission motor, stainless steel conveyor belt, infrared heating tube, and support frame. When food passes through a dryer, it quickly dries under clean conditions.

Power:40kw Maximum

Temperature:150 ℃

|

Model |

Installed capacity |

Power consumption |

Output |

Length |

|

CW65-I |

58KW |

38KW |

100~120KG/H |

16*1.2*2.2m |

|

CW70-II |

70KW |

45KW |

150~200KG/H |

18*1.2*2.2m |

|

CW85-II |

90KW |

60KW |

450~500KG/H |

20*1.5*3.2m |

|

CW90-II |

180KW |

150KW |

800~1200KG/H |

25*2.5*3.5m |

Member Information

| jinan mingde mi | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15253185023 |

| Contact: | ASH ZHANG (saleman) |

| Last Online: | 21 Nov, 2023 |