| Model: | - |

|---|---|

| Brand: | REBOUNDCNC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cutting & Fold-bend Machine |

| Label: | plasma cutting , gantry plasma cutter |

| Price: |

US $4000

/ pc

|

| Min. Order: | 1 pc |

Product Description

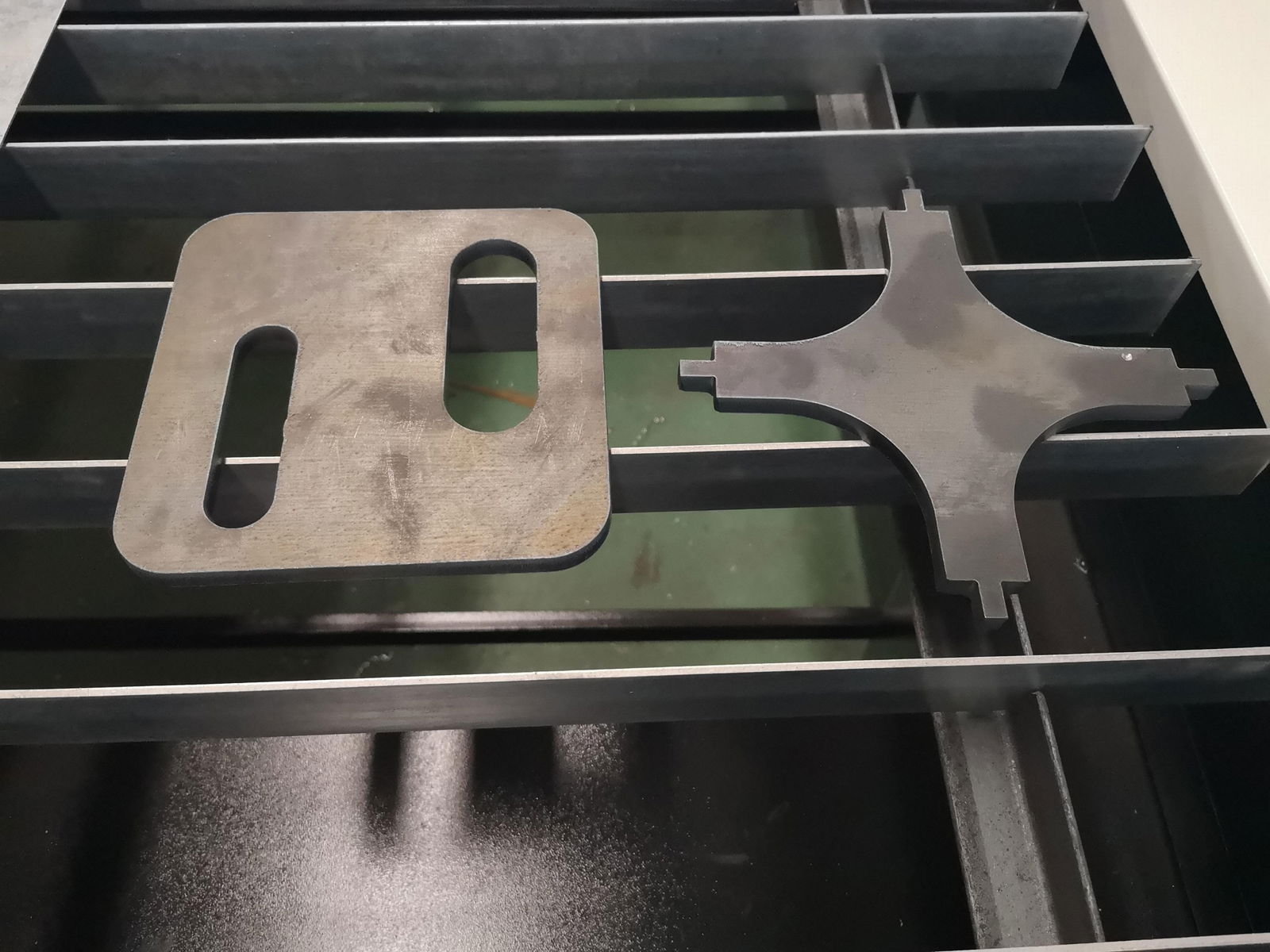

REBOUND 120 HD plasma generator CNC plasma cutting machine is mainly used for cutting various metal materials such as carbon steel, alloy steel, and non-ferrous metals.It is widely used in the installation of industrial power stations, boiler pressure vessels, metallurgy, petrochemical, aerospace, shipbuilding, engineering machinery, steel structure manufacturing and other metal cutting industries.

Specifications of REBOUND 120 HD plasma generator CNC plasma cutting machine:

1. 120 HD plasma generator

This CNC plasma cutting machine matches 120/200/300/400HD plasma generator.

(1) 100% (40℃) rated duty cycle, suitable for work in heavy industry;

(2) Adopt gas pressure sensor, the cutting torch can be properly protected when the gas pressure is too low;

(3) Adopt liquid flow sensor, the cutting torch can be properly protected when the liquid flow is too low, and the liquid flow is displayed on the display meter;

(4) The gas pre-flow time, gas post-flow time, current up-slope time can be separately set according to the torch cable length;

(5) The plasma gas pressure can be adjusted on the panel, the pressure is displayed on the meter, friendly operation;

(6) There is digital communication connector, can be connected with different automation equipment;

(7) With torch monitoring function, warning to change the consumables, to longer the torch working life;

(8) Intelligent fan is used to reduce the dust;

(9) With automatic protection of over-heating and lack-voltage.

2. Plasma control system

(1) This system is applicable for kinds of flame/plasma cutting machine CNC system, widely used in desktop CNC cutting machine of metal processing, advertisement, stone material industry, etc.

(2) The system is designed with high reliability, with plasma interference, lightning protection and surge capacity.

(3) Practical flame/plasma cutting process, plasma processing, automatic corner speed control, and control the block.

(4) We can use wireless remote control or wired control box to realize remote operation.

Back, passage and breakpoints in recovery, to choose the function such as perforation position, greatly convenient user manipulation.

(5) It Includes 24 kinds of graphics component library (customizable), contains the common basic processing parts.

(6) It works with STARCAM nesting software well, and at the same time compatible IBE (Germany), FASTCAM in major nesting software.

(7) Interface conversion, in both English and Chinese language. Also can be customized to other countries.

3. Plasma torch. REBOUND fine cutting torch

Strong perforation ability, good cutting perpendicularity, smooth cut surface.

For cutting processes with different currents and metal materials, consumables with good cutting quality are matched.

4. Plasma cutting machine torch height controller

The AVC168 torch height controller is a voltage sensing torch height control system that is designed for the CNC plasma cutting machines. During cutting process, the cutting current always keep constant, and the cutting arc voltage will be changed with the height of torch. When the distance between the torch nozzle and work piece increases, the arc voltage increases, on the opposite, the arc voltage will decrease. AVC168 plasma arc voltage torch height controller will detect the voltage changes, then control the distance between cutting torch and work piece via the lifting motor in order to keep the arc voltage within a given range, so that the height of cutting torch is kept within a corresponding range.

5. Fast CAM software

Fast CAM software is an advanced line drawing system that has been developed specifically for CNC controlled, two dimensional cutting equipment (Like CNC plasma cutting machine ). The program is menu & Icon driven, and easy to use. In many of the constructions the computer will know which part of an arc,or what fillet blend is required, by how the point is selected. This is in contrast to most CAD systems that play twenty questions to determine the correct construction. Because of the "dead obvious" philosophy, the drawing system is more interactive than interrogative.

6.Servo driving system.

Member Information

| Jinan Rebound CNC Machine Co.,Ltd. | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 54685180 |

| Contact: | Caidi (sales) |

| Last Online: | 01 Apr, 2024 |

Related Products of this Company

-

Industrial 4*8 table CNC plasma cutter

US $4500

-

Affordable lgk hypertherm light gantry

US $4500

-

RB-6000 round steel tube tube CNC plasma

US $4500

-

RB 1530-H water jet plasma CNC cutting

US $4000

-

1530 steel/iron plate CNC table plasma

US $5000

-

3000*6000MM smokeless Hypertherm Gantry

US $4500

-

Metal tube tube CNC plasma cutting

US $4500

-

RB 1530 portable CNC plasma flame

US $1500

-

2040 1530 thin mild steel sheet CNC

US $4000

-

RB1530-P steel plate and tube portable

US $5000