| Model: | - |

|---|---|

| Brand: | TOPTITECH |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Filters |

| Label: | titanium mesh , filter mesh , mutilayer mesh |

| Price: |

US $20

/ pc

|

| Min. Order: | 5 pc |

Product Description

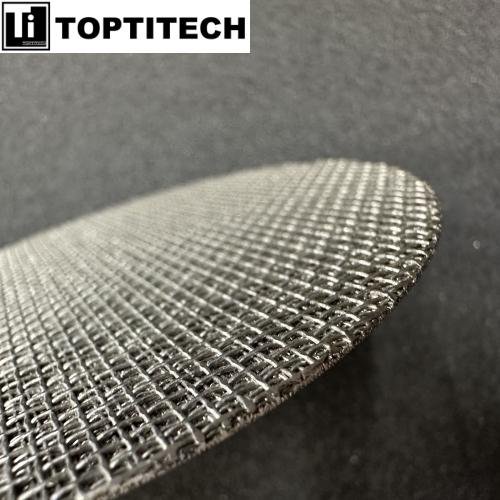

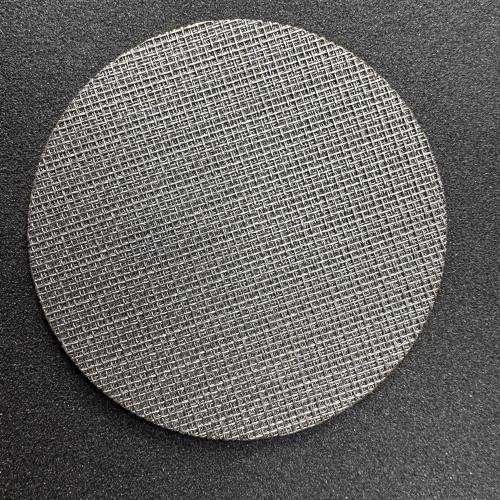

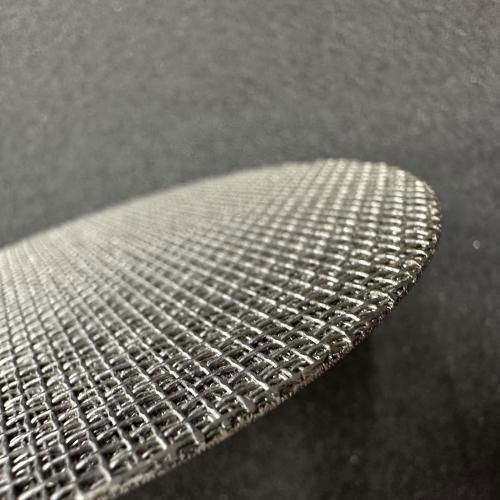

1.0mm thickness sintered multi-layer titanium woven mesh

The sintered multi-layer titanium woven mesh with a thickness of 1.0 mm is an innovative metal filter material that offers exceptional performance and a wide range of applications. This woven mesh panel is created by sintering multiple layers of titanium mesh together, resulting in a robust and durable structure.

By sintering titanium mesh with different mesh sizes, customized products can be manufactured, enhancing the strength and corrosion resistance of the material. This unique combination makes it an incredibly versatile solution.

Parameters

Material: Gr1 Titanium

Size: 100*100*1.0mm thick

Type: sintered woven mesh

Hole size: customized (each layer with different hole size)

Key Features:

Multi-layer Woven Structure: The woven mesh panel is meticulously crafted by interweaving multiple layers of fine-wire titanium mesh, resulting in a strong and highly adjustable pore structure. This design enables the mesh to effectively filter particles of varying sizes and shapes, catering to diverse filtration requirements.

High Permeability and Flow: Despite its fine pore structure, the sintered multi-layer titanium woven mesh offers excellent permeability and flow characteristics. Each individual fine-wire titanium mesh is incredibly small, providing numerous channels for fluid to swiftly pass through the mesh panel, ensuring efficient filtration and separation.

Superior Temperature and Corrosion Resistance: Titanium metal inherently possesses remarkable resistance to high temperatures and corrosion. As a result, the sintered multi-layer titanium woven mesh can reliably operate in demanding high-temperature environments and withstand the corrosive effects of various chemicals and media.

Customizability and Adaptability: This mesh panel can be readily customized in terms of size, shape, and aperture to meet the specific requirements of different applications. Its excellent plasticity allows for further processing and shaping, enabling seamless integration into complex filtration systems and equipment.

Applications:

Petroleum and Chemical Industry: Widely utilized in the filtration and separation of liquids and gases within the petroleum and chemical industry. It finds application in crude oil and natural gas pretreatment, catalyst separation and recovery, as well as the purification of chemical products. For instance, in catalyst regeneration processes at refineries, the woven mesh effectively removes residual catalyst particles, enhancing the efficiency of catalyst regeneration.

Food and Beverage Industry: Employed in the food and beverage industry for the filtration, clarification, and removal of impurities from liquids. It effectively eliminates suspended solids, microorganisms, and other contaminants, ensuring product purity and hygiene. In addition to hop filtration, it is also utilized for the filtration and purification of juices, alcohol, drinking water, and more.

Medical Field: Due to its excellent biocompatibility and corrosion resistance, the sintered multi-layer titanium woven mesh finds extensive application in the medical field. It serves as a filter and support material for implants, such as artificial joints and dental implants. Moreover, it is utilized in the manufacturing of filter components for artificial organs and medical devices, including artificial heart assist devices.

Tissue Engineering and Regenerative Medicine: The sintered multi-layer titanium woven mesh panels play a pivotal role in tissue engineering and regenerative medicine. They serve as scaffold materials for cell culture and tissue engineering, providing support and guidance to cells, thereby promoting tissue regeneration and repair.

Member Information

| TOPTITECH(Baoji Yinggao Metal Materials Co., Ltd.) | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 19909178529 |

| Contact: | Lisa Yue (sales manager) |

| Last Online: | 26 Oct, 2024 |

Related Products of this Company

-

1 micron Stainless Steel Sintered Wire

US $56.98

-

30 Inch 5 Micron 226/Fin Adpator SS316L

US $36

-

0.45um Double-opened Titanium Powder

US $27.78

-

Sintered stainless steel filters as

US $20

-

Dia 5mm Ti Getter For Vacuum System

US $0.6

-

3-Layer Stainless Steel Wire Mesh Filter

US $56.43

-

10um Porous Titanium Plate With Chamfers

US $3.58

-

Sintered SUS316L Wire Mesh Filter Tube

US $23.9

-

GR1 Titanium Filter Tube for Inline

US $20