| Model: | - |

|---|---|

| Brand: | BOOSUM PRECISION |

| Origin: | - |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | Automatic shaft dete , Micro motor shaft st , Motor shaft inspecti |

| Price: |

US $22000

/ pc

|

| Min. Order: | 1 pc |

Product Description

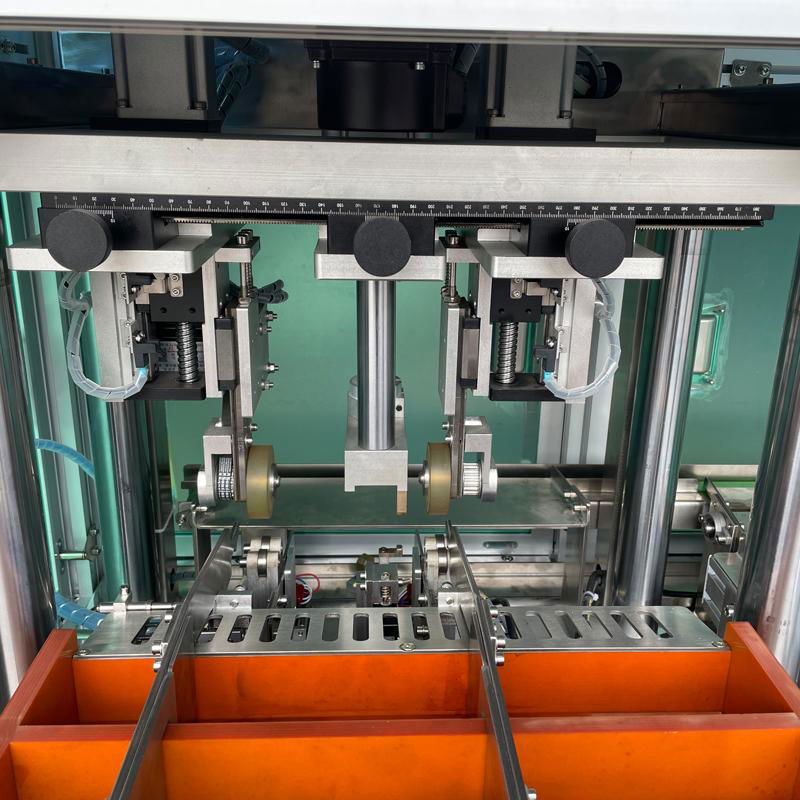

The motor shaft core dynamic detection and straightening machine is an efficient and accurate industrial equipment mainly used for the dynamic detection and straightening of motor shaft cores. Here is a brief introduction to the device:

1、 Main functions

The motor shaft core dynamic detection and straightening machine integrates advanced dynamic detection technology and straightening technology, which can real-time detect key parameters such as bending and straightness of the motor shaft core, and precisely adjust the shaft core through an automatic straightening system to ensure that the accuracy and quality of the shaft core meet the standard requirements.

2、 Technical characteristics

High precision detection: By using highly sensitive sensors and advanced detection algorithms, precise detection of small deformations in the motor shaft core can be achieved.

Dynamic straightening: Through the dynamic straightening system, the shaft core can be straightened in real-time during the inspection process, improving production efficiency.

Automated operation: The equipment has functions such as automated loading and unloading, automatic detection, and automatic straightening, reducing the complexity and error rate of manual operations.

Intelligent control: Adopting advanced PLC control system and touch screen operation interface, it is convenient for users to set parameters and monitor equipment.

3、 Applicable scope

The motor shaft core dynamic detection and straightening machine is suitable for various specifications and types of motor shaft cores, such as DC motors, AC motors, stepper motors, etc. It is widely used in motor production lines in industries such as automobiles, electric tools, and household appliances, providing strong support for improving product quality and production efficiency.

4、 Advantages and Value

By using this equipment, enterprises can achieve strict control over the quality of motor shaft cores, reduce the occurrence of non-conforming products, and lower production costs. At the same time, the automation operation of the equipment also reduces the labor intensity of workers and improves work efficiency. In addition, precise straightening technology can also extend the service life of the motor and improve the overall performance of the product.

In short, the motor shaft core dynamic detection and straightening machine is a powerful and technologically advanced industrial equipment, which is of great significance for improving the automation level and product quality of the motor production line.

Number

Basic project

parameter

one

Servo tonnage

1. T

two

Straightening rhythm approximately/minute

6-9 pieces

four

Straightened product length range mm

90-280

five

Straightened product outer diameter range mm

6-12

six

Straightening tolerance range nm

± 0.01nm

nine

Number of parts that can be placed in the silo

300-500 pieces

ten

Loading method

Push plate

eleven

Cutting method

Conveyor belt

sixteen

Control system (PLC or other methods)

SMT machine system

seven

Frame aluminum profile specification (length * width) mm

80 * 40

twenty

Machine bed color

RAL7035 flat glossy white

twenty-one

Equipment size: length * width * height

1200 * 980 * 1700

twenty-two

Equipment weight kg

500kg

Member Information

| Boosum Precision Machinery Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18688997860 |

| Contact: | MR.Sam (Business Manager) |

| Last Online: | 18 Aug, 2024 |

Related Products of this Company

-

Automatic milling and cutting machine

US $11000

-

Automatic slotting machine

US $20000

-

Automatic milling flat machine

US $10000

-

Multi functional automatic milling flat

US $10500

-

Precision milling flat machine

US $20000

-

Bar hight speed automatic cutting

US $11000

-

hydraulic punching machine for making 4

-

Automatic chamfering machine

US $15000

-

Shaft Automatic milling flat machine

US $10000

-

Double head automatic drilling machine

US $10000