| Model: | ZPR700 |

|---|---|

| Brand: | Zhipeng |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Valves |

| Label: | ball valve , pneumatic ball valve , Metallic Ball valve |

| Price: |

US $1

/ pc

|

| Min. Order: | 1 pc |

Product Description

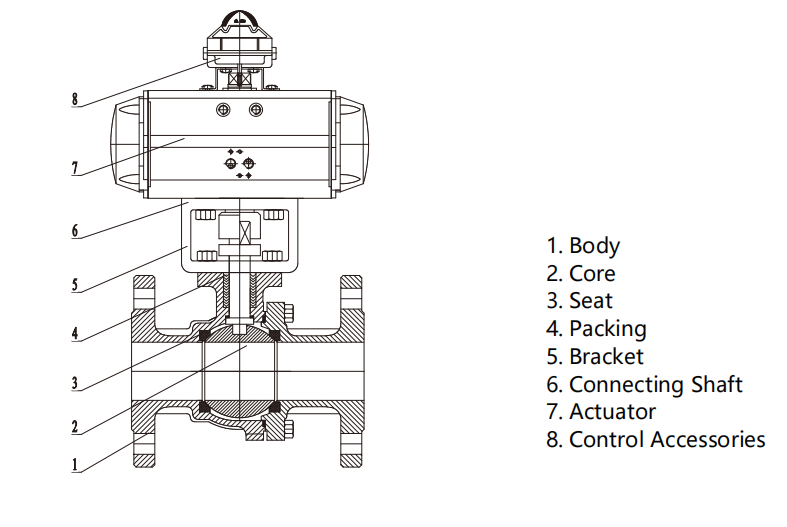

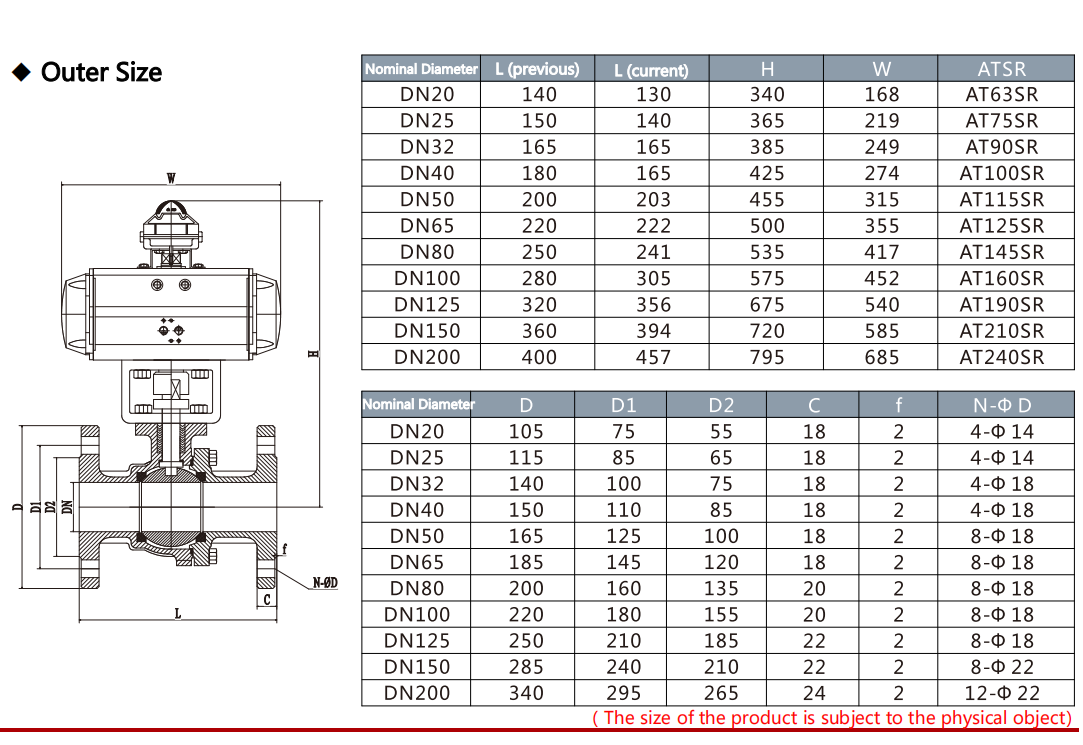

High Temperature And High Pressure Cut-Off Metallic Ball Valve 304/316 Stainless Steel Valve With Pneumatic/Electric Actuator Regulating/Control Valves(ZPR700)

Products Overview

The ZPR700 series metallic cut-off ball valve features a high fluid capacity, compact structure, excellent sealing performance, long

service life, cost-effectiveness, and easy maintenance. It finds extensive applications in industries such as petroleum, chemical, natural gas, electric power, metallurgy, food processing, and pharmaceuticals. Moreover, it can be utilized for water treatment systems,steam, oil, liquefied gas (LPG), natural gas (NG), and coal gas mediums. Additionally, the fireproof option and special hardening treatment are available to meet customer requirements for enhanced safety and broader applications.

Classification Of Metallic Cut-Off Valves:

1.ZPR750F:Soft-Sealing O-Shaped Cut-Off Ball Valve

2.ZPR750Y:Hard-Sealing O-Shaped Cut-Off Ball Valve

3.ZPR760F:V-Shaped Regulating Ball Valve

4.ZPR770F:Three-way reversing ball valve

5.ZPR780F:O-Shaped Discharge Ball Valve

6.ZPR790F:Four-way reversing ball valve

Application And Characteristics

The ZPR750F Soft-Sealing O-Shaped Cut-Off Ball Valve features a compact and reliable structure, ensuring excellent sealing performance. Its easy maintenance, while the closed state of the sealing surface and ball surface minimizes erosion from the medium. This valve is easy to operate and maintain, suitable for the common mediums like water, chemical solvents, acids, natural gas. It can also withstand harsh conditions such as Oxygen, hydrogen peroxide, methane and ethylene,etc.

As a result of its versatility and durability, it finds extensive applications across various industries.

1. Ball valves exhibit minimal flow resistance due to their low fluid resistance.

2. With a simple structure, small size, and light weight, they are highly convenient for various applications.

3. The ball valve have two tight and reliable sealing surfaces, commonly made of plastic materials, ensure excellent sealing

performance and complete isolation in vacuum systems.

4. Operating the valve is effortless as it only requires a 90° rotation from full open to full close position, allowing for easy remote

control.

5. Maintenance is hassle-free with the easily disassembled and replaceable movable sealing rings in the simple structure of the

ball valve.

6. When fully open or closed, the ball and valve seat sealing surface effectively isolates the medium without causing erosion on the

valve seat surface.

7. Ball valves have a wide range of applications.The diameters from a few millimeters to few meters, suitable for both high vacuum

and high-pressure conditions.

8. The wiping action during opening and closing enables ball valves to be used in media containing suspended solid particles.

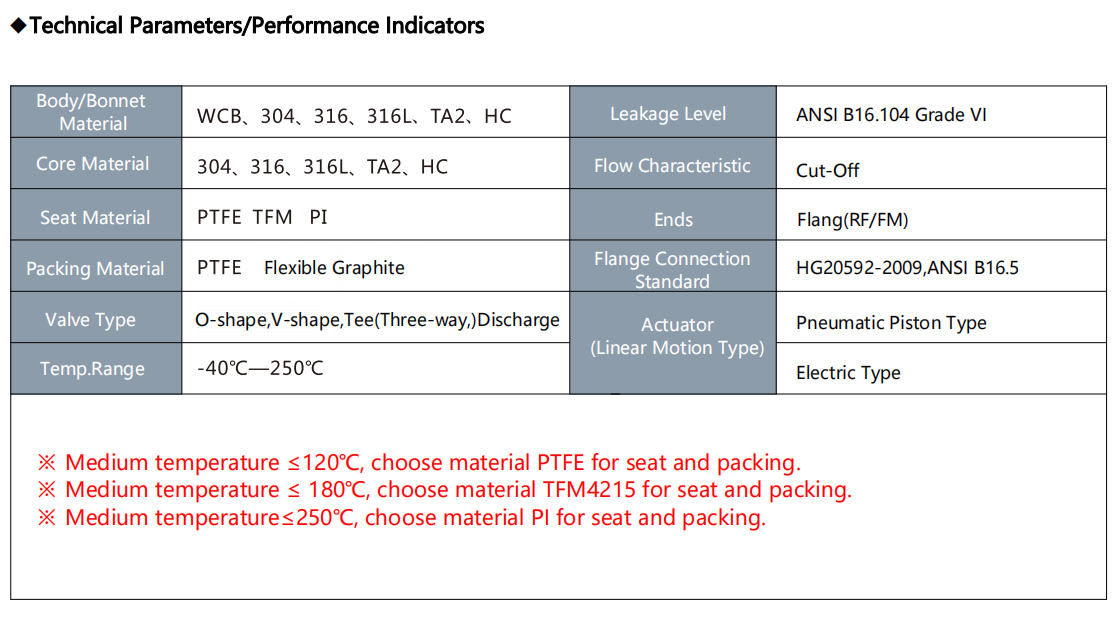

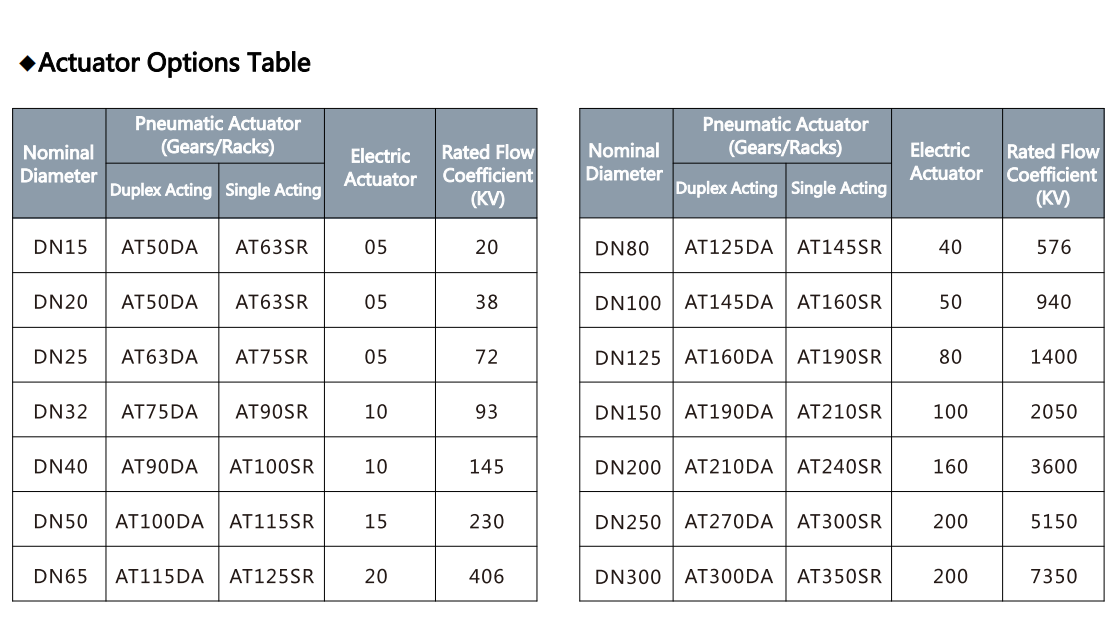

Technical Parameters/Performance Indicators

| Body/Bonnet

Material |

WCB,304,316,316L,TA2,HC | Leakage Level | ANSI B16.104 Grade VI |

| Core Material | 304,316,316L,TA2,HC | Flow Characteristic | Cut-Off |

| Seat Material | PTFE TFM PI | Ends | Flang(RF/FM) |

| Packing Material | PTFE Flexible Graphite | Flange Connection

Standard |

HG20592-2009,ANSI B16.5 |

| Valve Type | O-shape,V-shape,Tee(Three-way,)Discharge | Actuator

Linear Motion Type) |

Pneumatic Piston Type |

| Temp.Range | -40ºC-250ºC | Electric Type |

Member Information

| Zhipeng Valve Group Co.,Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 18968946889 |

| Contact: | Vic Chan (Trade Manager) |

| Last Online: | 11 Jun, 2024 |