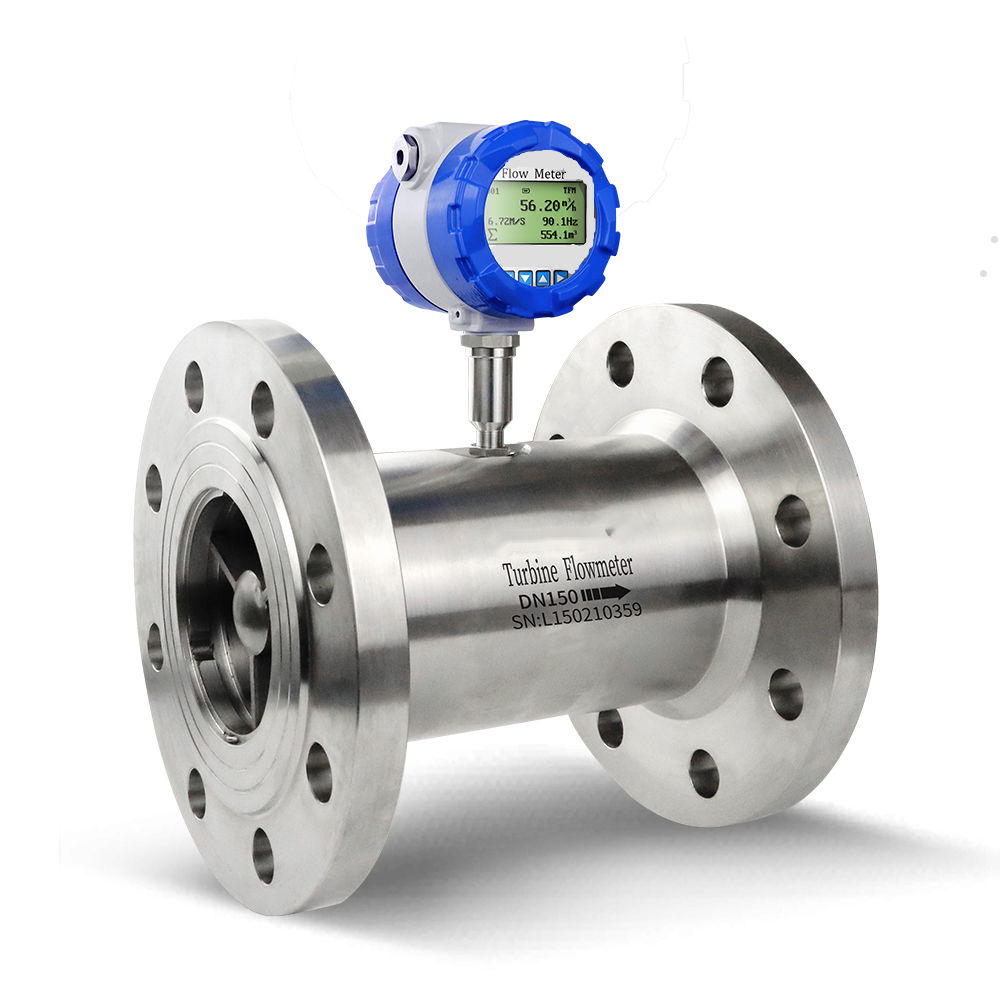

The turbine flow meter is based on the torque balance principle and belongs to the speed flowmeter. The sensor has the advantages of simple structure, energy saving, high precision, lightweight, good repeatability, sensitive response, easy installation, maintenance, and use. Widely used in chemical, petroleum, water supply, metallurgy, paper, and other industries. It is suitable for measuring stainless steel 1Cr18Ni9Ti, corundum AI203, 2Cr13, cemented carbide, and other non-fiber, non-corrosive, particles and other impurities of the liquid. If it is equipped with a display instrument with special functions, it can be quantitative control and over-alarm. The explosion-proof version of this product (ExdIICT6 Gb) is suitable for an explosion-hazard environment.

Parameters

- Precision: DN4-DN10: ±1.0%R; DN15-DN100: ±0.5%R; DN125-DN200: ±1.0%R

- Ratio of Measuring Range: 1: 10

- Instrument Material: Sensor:SS304 (SS316L) ; Impeller: 2Cr13 , Guide: SS304 , Bearing YS8 Alloy (special material can be customized)

- Conditions of use: Environment temperature: -30°C-60°C; Medium temperature: -20°C-80C(120°C/150C

- Pressure Level: Threaded connections:6.3MPa

Flange connections :2.5MPa

Clamp connections :1.0MPa

- Power Consumption: ≤2W

- Power supply: 3.6V lithium battery /12-24VDC

- Signal Output: Pulse / 4-20mA/ RS485 (Modbus-RTU)

- Signal Interface: Internal thread M20*1.5(NPT1/2, etc needs to be customized)

- Protection Level: P65 (lP68 can be customized)

- Explosion-proof Level: ExdllCT6 Gb (Optional)

- Display: LCD Display: Instantaneous flow , Accumulative flow