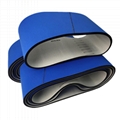

For slitting metal coil: such as slitting strip steel, stainless steel, copper strip, aluminum foil, etc. The slitting machine belt supports the material being slit, providing a stable surface for the slitting knives or blades to cut accurately. Puteken mainly offer three kinds of slitting machine belt as below:

- Dry Type Slitting Machine Belt

The belt surface is wear resistant and cutting resistant PU, which protects the surface of the belt is not easy to be scratched and extends the belt life service. The intermediate uses high elastic fiber, which ensuring the belt provides a balanced tension to the steel plate and minimizes the relative movement between the belt and the metal plate. The bottom layer adopts high-strength polyester filament, which has high tensile strength and good toughness and meet the needs of high-speed operation. It is often used for slitting dry steel plates.

- Oil Type Slitting Machine Belt

The belt surface PU has a pattern, which is wear resistant and cutting resistant and has good friction. It can protect the belt surface from scratching, extend the service life of the belt. There is a hole in the middle surface to permeate the oil.It is widely used for slitting oil steel plate.

- Leather Type Slitting Machine Belt

The belt surface leather has features of high wear resistance, and the fine leather can prevent the slightest scratch on the surface of the steel plate. And resistant to high temperature and wear.

For more information, please feel free to contact us through searching keyword “Puteken”.