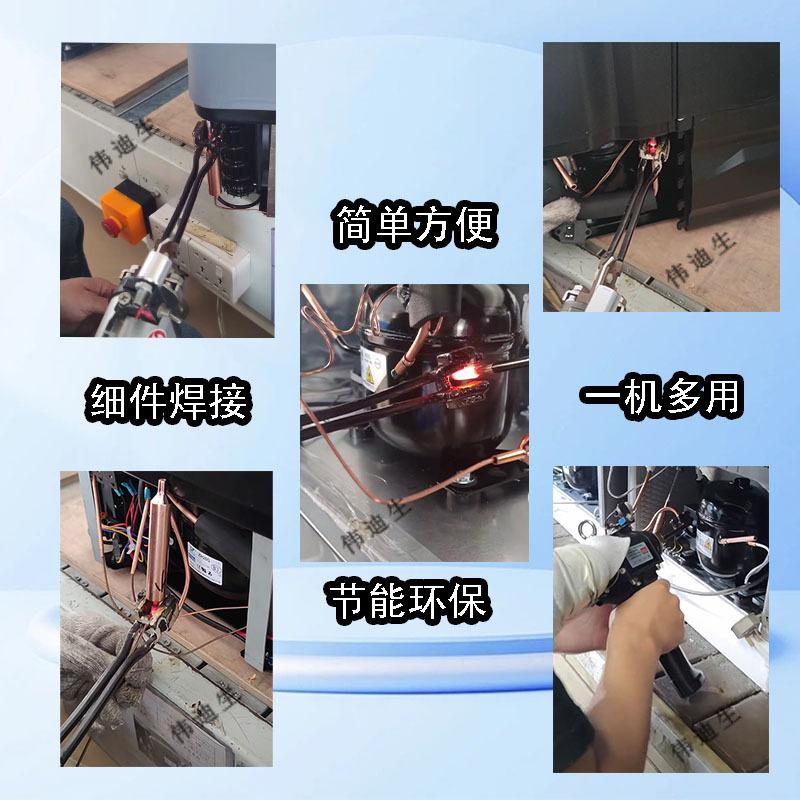

afe operation without open flames: The handheld high-frequency welding machine uses high-frequency induction heating technology to generate eddy currents inside the copper tube through electromagnetic induction to achieve rapid heating to the welding temperature. The entire process does not require an open flame, greatly reducing fire risks and increasing output. Safety. Efficient and accurate: High-frequency heating technology can heat copper pipes quickly and evenly, shorten the welding cycle and improve production efficiency. At the same time, due to the fast heating speed and controllable temperature, the quality of welded joints can be ensured and welding defects can be reduced. Environmental protection and energy saving: Compared with traditional flame welding methods, handheld high-frequency welding machines do not produce harmful gases and smoke during the welding process, reducing environmental pollution. At the same time, the energy efficiency of high-frequency heating technology is greatly improved compared with traditional welding methods, significantly reducing energy consumption.