| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metal Mineral |

| Label: | - |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Brief Introduction

XZM Ultrafine mill is high efficiency and low consumption ultrafine processing equipment which is designed by our engineers and technicians on the basis of multiple innovation, test and more than twenty-year experience in mill manufacture. This mill has absorbed many advantages of home and aboard mill manufacturing technique. It is the representation of leading level of high quality grinding machine. It is proved that our product has perfect performance and high quality.

Features

1.High capacity and low consumption

Under the same final fineness and power, the capacity of XZM Ultrafine mill can be improved 40%, while the consumption reduced greatly, compared with jet mill and mixing mill.

2.Easy fineness adjustment and high fineness

The final fineness can be adjusted according to requirements, and the fineness can reach D97≦5um.

3. Reliable Security

There is no rolling bearing and bolt in the mill chamber, therefore, the bearing and sealing elements will not wear out easily, and the bolts will not loose to make damage to the equipment.

4. Clean, environmental protection

Equipped with pulse filter and silencer, the mill reduces

dust and noise greatly, which reaches State Environmental-protection Standard

Application

XZM Ultrafine mill is a machine for producing fineness and ultra-powder. It is mainly used for grinding the materials whose hardness is middle and low, moisture below 6%, and Moths hardness should be blow 9 grade and non-explosion and non-flammability, such as: calcite, chalk, limestone, dolomite, kaolin, bentonite, steatite, mica, magnesite, illite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc.

Working Principle

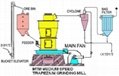

The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of roller which are rolling in the ring, which are driven by dial through plunger. After crushed by hammer crusher, the big materials become small sizes ones and they are sent to storage bin by elevator. The electromagnetic vibrating feeder will send them to the middle of first dial evenly, the materials will be driven to the edge of dial by centrifugal force, and fall down into the ring and crushed and grinded by roller, then the materials will fall down into the second and third ring, and crushed and grinded. The high pressure centrifugal blower will inhale air from the outside and blow the materials which are grinded in the third ring to powder classifier. The rotating turbo in the powder concentrator will make the coarse materials return to the mill and

reground, while the fineness will mix with the air and go into the cyclone and be discharged the discharge valve which is in the bottom of it. The air which mixed with very little fineness will be purified by impulse duster and discharged by blower and muffler.

Composition and Structure

The standard configuration of XZM ultrafine mill consists of main unit, powder classifier, double cyclone collectors, pulsed filter, blower, motor, pipes and muffler. The optional accessories include jaw crusher, hammer crusher, elevator, feeder, and control cabinet.

There are bearing pedestal and blowing case on the main machine base. There is grinding case on the blowing case, whose middle part has multilayer dial equipping on the main bearing. On each dial, there are numbers of roller, and there are corresponding ring for each dial. There are two class screwing gear reducer and electromotor in the base of main machine. The powder classifier is equipped on the top of grinding chamber.

Main specification

Tab 1:

item XZM215 XZM221 XZM227

Number of roller(piece) 15 21 27

Ring diameter(mm) φ 600 φ 800 φ1000

Number of ring (piece) 2 2 2

main equipment rotate speed(r/min) 235 235 235

Max. inlet size(mm) <10 <10 <10

Final size (mesh) 325-2500 325-2500 325-2500

Capacity(kg/h) 350-2500 600-4000 900-6000

Overall size(m) 10×2×5.5 12.4×2.5×5.8 14.5×3.8×6.3

Note: If there is any change of above specification, it is all according to the booklet with machine.

Tab2:

Basic data Item Unit specification

XZM215 XZM221 XZM227

motor of main machine Model Y250-4 Y250-4 Y250-4

Power kw 37 55 90

classify Frequency

modulation motor

Model Y180M-4 Y180M-4 Y180M-4

Power kw 11 18.5 30

Motor of elevator Model Y100L-4 Y100L-4 Y100L-4

Power kw 3 3 3

Motor of blower Model Y225M-2 Y225M-2 Y225M-2

Power kw 30 45 75

Hammer crusher Model 250-400 250-400 250-400

Power kw 5.5 5.5 5.5

Electromagnetism Vibrating feeder Model GZ1F GZ1F GZ1F

Power kw 0.06 0.06 0.06

discharge valve Model ZJD-1:40 ZJD-1:40 ZJD-1:40

Power kw 0.75 0.75 1.1

Pulsed duster Model BMC72-11 BMC72-11 BMC72-11

Power kw 3 3 3

Note: If there is any change of above specification, it is all according to the booklet with machine.

XZM Ultrafine mill is high efficiency and low consumption ultrafine processing equipment which is designed by our engineers and technicians on the basis of multiple innovation, test and more than twenty-year experience in mill manufacture. This mill has absorbed many advantages of home and aboard mill manufacturing technique. It is the representation of leading level of high quality grinding machine. It is proved that our product has perfect performance and high quality.

Features

1.High capacity and low consumption

Under the same final fineness and power, the capacity of XZM Ultrafine mill can be improved 40%, while the consumption reduced greatly, compared with jet mill and mixing mill.

2.Easy fineness adjustment and high fineness

The final fineness can be adjusted according to requirements, and the fineness can reach D97≦5um.

3. Reliable Security

There is no rolling bearing and bolt in the mill chamber, therefore, the bearing and sealing elements will not wear out easily, and the bolts will not loose to make damage to the equipment.

4. Clean, environmental protection

Equipped with pulse filter and silencer, the mill reduces

dust and noise greatly, which reaches State Environmental-protection Standard

Application

XZM Ultrafine mill is a machine for producing fineness and ultra-powder. It is mainly used for grinding the materials whose hardness is middle and low, moisture below 6%, and Moths hardness should be blow 9 grade and non-explosion and non-flammability, such as: calcite, chalk, limestone, dolomite, kaolin, bentonite, steatite, mica, magnesite, illite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc.

Working Principle

The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of roller which are rolling in the ring, which are driven by dial through plunger. After crushed by hammer crusher, the big materials become small sizes ones and they are sent to storage bin by elevator. The electromagnetic vibrating feeder will send them to the middle of first dial evenly, the materials will be driven to the edge of dial by centrifugal force, and fall down into the ring and crushed and grinded by roller, then the materials will fall down into the second and third ring, and crushed and grinded. The high pressure centrifugal blower will inhale air from the outside and blow the materials which are grinded in the third ring to powder classifier. The rotating turbo in the powder concentrator will make the coarse materials return to the mill and

reground, while the fineness will mix with the air and go into the cyclone and be discharged the discharge valve which is in the bottom of it. The air which mixed with very little fineness will be purified by impulse duster and discharged by blower and muffler.

Composition and Structure

The standard configuration of XZM ultrafine mill consists of main unit, powder classifier, double cyclone collectors, pulsed filter, blower, motor, pipes and muffler. The optional accessories include jaw crusher, hammer crusher, elevator, feeder, and control cabinet.

There are bearing pedestal and blowing case on the main machine base. There is grinding case on the blowing case, whose middle part has multilayer dial equipping on the main bearing. On each dial, there are numbers of roller, and there are corresponding ring for each dial. There are two class screwing gear reducer and electromotor in the base of main machine. The powder classifier is equipped on the top of grinding chamber.

Main specification

Tab 1:

item XZM215 XZM221 XZM227

Number of roller(piece) 15 21 27

Ring diameter(mm) φ 600 φ 800 φ1000

Number of ring (piece) 2 2 2

main equipment rotate speed(r/min) 235 235 235

Max. inlet size(mm) <10 <10 <10

Final size (mesh) 325-2500 325-2500 325-2500

Capacity(kg/h) 350-2500 600-4000 900-6000

Overall size(m) 10×2×5.5 12.4×2.5×5.8 14.5×3.8×6.3

Note: If there is any change of above specification, it is all according to the booklet with machine.

Tab2:

Basic data Item Unit specification

XZM215 XZM221 XZM227

motor of main machine Model Y250-4 Y250-4 Y250-4

Power kw 37 55 90

classify Frequency

modulation motor

Model Y180M-4 Y180M-4 Y180M-4

Power kw 11 18.5 30

Motor of elevator Model Y100L-4 Y100L-4 Y100L-4

Power kw 3 3 3

Motor of blower Model Y225M-2 Y225M-2 Y225M-2

Power kw 30 45 75

Hammer crusher Model 250-400 250-400 250-400

Power kw 5.5 5.5 5.5

Electromagnetism Vibrating feeder Model GZ1F GZ1F GZ1F

Power kw 0.06 0.06 0.06

discharge valve Model ZJD-1:40 ZJD-1:40 ZJD-1:40

Power kw 0.75 0.75 1.1

Pulsed duster Model BMC72-11 BMC72-11 BMC72-11

Power kw 3 3 3

Note: If there is any change of above specification, it is all according to the booklet with machine.

Member Information

| Shanghai Zenith Electric Power Equipment Co., Ltd | |

|---|---|

| Country/Region: | China |

| Business Nature: | Manufacturer |

| Phone: | 0086-21-58106296 581 |

| Contact: | Alan Cao (sales asistant) |

| Last Online: | 11 Sep, 2006 |