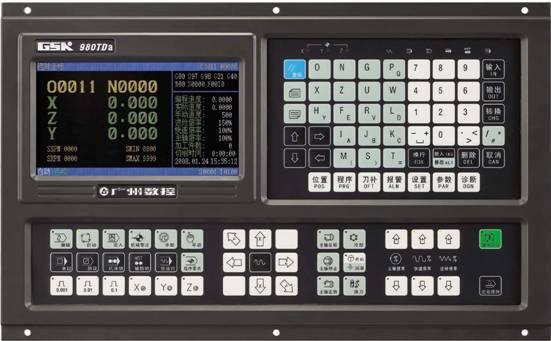

| Model: | GSK980TDb |

|---|---|

| Brand: | GSK |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | CNC SYSTEM , CNC CONTROLLER , CNC TURNING CONTROL |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

GSK980TDb(Upgraded from GSK980TDa) CNC Turning center/lathe controller: 2 Analog spindle plus 5 feed axes (including C axis), LCD with graphics display, 0.001mm distinguishability, PLC ladder program, 2 axes line/ arc interpolation, DNC communications

1-Five axes of X, Z, Y, 4th and 5th control, the axial name and type of Y, 4th and 5th can be defined.

2-2ms interpolation cycle, precision of 1um or 0.1um can be selected.

3-Maximum speed 60m/min (When it is 0.1um, the maximum speed is 24m/min).

4-Adapted servo spindle can realize spindle continuous position, rigid tapping, rigid screw processing

5-Built-in many PLC programs, the current running PLC program can be selected

6-G71 command supports the cycle cutting of groove shape outline

7-Support the programming of macro command in sentence type and the calling of macro program with parameter.

8-Support programming in metric system/inch system, with function of auto tool-setting, auto chamfering, tool life management.

9-Display in Chinese, English, Spanish or Russian, which is selected by parameter.

10-With USB interface, it supports file operation in flash disk, system configuration and software upgrade.

11-Analog voltage output of 0V~10V in two channels, support double spindles

12-Electrical MPG input in one channel, it supports hand electrical MPG.

13-Common input in 40 points/common output in 32 points

14-Overall installation dimension and the command system are completely compatible with GSK980TDa.

Control function Controlled axis:X,Z, Min. command unit:0.001mm Interpolation ways:X,Z axis linear, circular interpolation Programming command range:+-9999.999mm Max. rapid speed:7600mm/min 30000mm/min(adaptive) Max. feed speed: linear speed 7600mm/min(electric gear ratio 1:1) Feed per rev:0.001~500mm/Rev(must equipped with 1024 P/r spindle coder) Feedrate override:0~150% 16 grades tune real time Rapid override:25%,50%,75%,100% Acceleration/deceleration mode:the linear rapid acceleration/ deceleration, the index feed acceleration/deceleration,the parameter can be tuned electric gear ratio:1~127/1~127 Electronic handwheel function: with Display windows Monitor display type:320X240 lattice in blue(LCD),CCFL in a poor light Display mode: Chinese(adaptive English menu) Diagram display function: with G function 23 kinds of G command, including 3 single fixed and 7 compound cycle commands, 8 user read/ write macro commands, max. 16 input/6 output points, double subprogram call, user macro program call Thread function Metric/Inch single straight thread, taper thread, metric/inch face thread. And the ending of thread can be set( set by the parameter) Pitch:0.001~500.000mm(metric) 0.06~254000.000 tooth/inch ( Inch) Spindle coder:1024p/r incremental coder Compensation function Backlash compensation:(X,Z axis) Pitch error compensation:(X,Z axis)(adaptive) Tool point radius compensation:(X,Z axis)(adaptive) Tool compensation:16 groups tool length compensation Tool function Adaptive toolpost:max. setting 8 tool selections electric toolpost(can adapt 12 tool selections toolpost function, select the near toolpost without chuck/tailstock control function) Tool selection signal input mode:directly input Tool change mode:MDI/automatic absolute tool change or manual relative tool change, tool selection by forward rotation, clamp by backward rotation Toolsetting mode: fixed point and trial cutting toolsetting Tool compensation mode: move the tool/coordinate offset(set by parameter) Spindle control Control mode: 4-gear or analog control Gear control:S1,S2,S3,S4 direct output Analog control: set as 4-gear spindle auto or manual shifting, and output 0~10V control spindle speed Constant linear cutting function: with( its function is valid when select the spindle analog control) Auxiliary function Control the spindle start/stop, reverse, stop; coolant On/Off; lubricate start/stop; chuck clamp/unclamp; tailstock feed/retract in Manual/MDI; control the spindle frequency conversion automatic shifting in MDI/Auto mode Program edit Program capacity:40KB,63 programs Subprogram:can be edited Communication Standard RS232 communication interface;adaptive communication function and supplying for the communication software and cable, transmitting the program with PC each other Anti-interference ability Meet GB/T17626.2 Adaptive part Switch power supplying:GSK PB(match with it and have been installed and connected) Driving device:DF3A 3-phase response,DY3B 3-phase compound,DA98 series AC servo Toolpost controller:GSK TB Assembly Standard panel,big panel, box Integrated outing wire from the bottom/back(matching with DF3A or DY3B) Dimension 420x260x136mm/ 420x320x136mm(samll/big) Weight 6.0kg(containing switch power supplying)

Member Information

| Gsk CNC Equipment CO.,LTD. | |

|---|---|

| Country/Region: | China |

| Business Nature: | Manufacturer |

| Phone: | 008613925042139 |

| Contact: | Huang Jian (Sales Manager) |

| Last Online: | 21 Apr, 2016 |