Markingchu@126.com

Mobile:+86-13502893727

------------------------------------

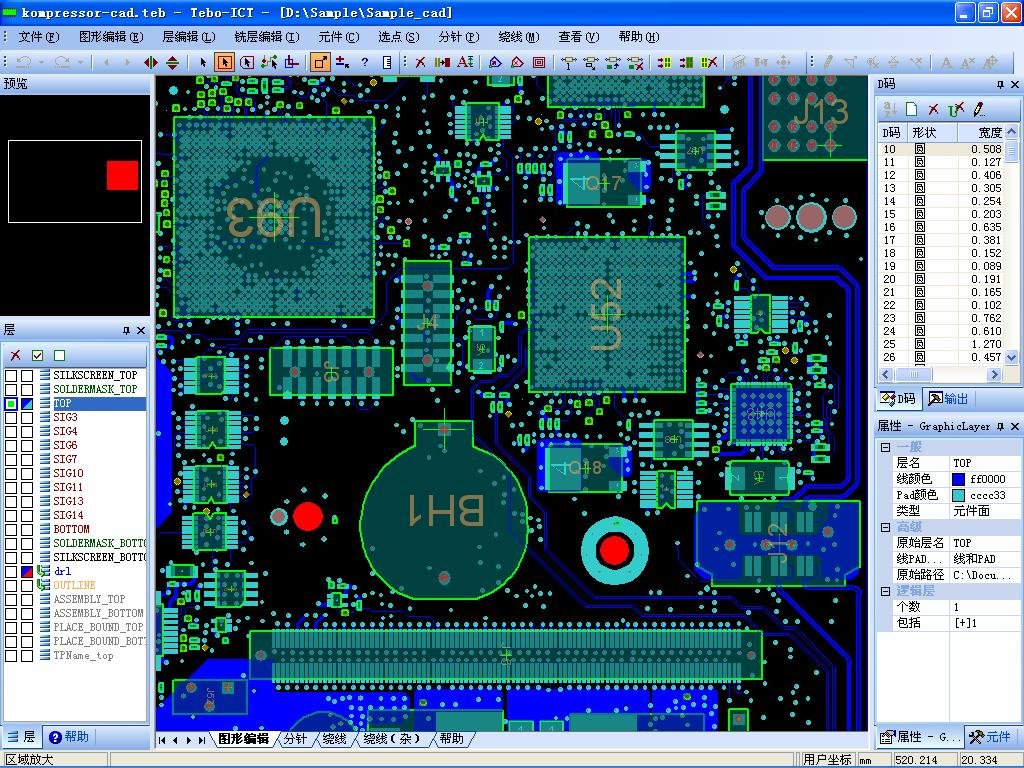

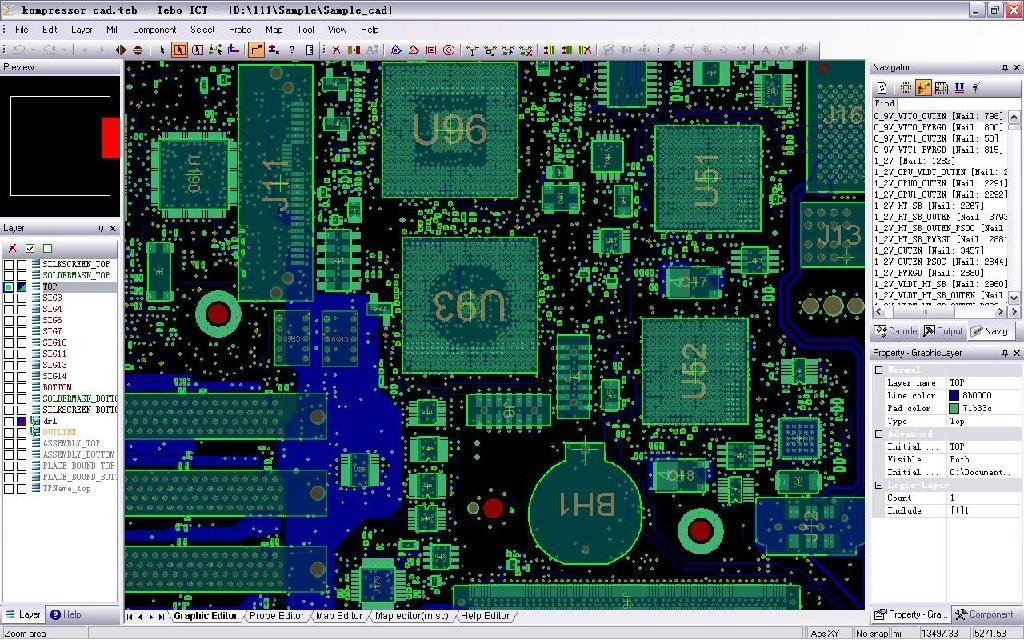

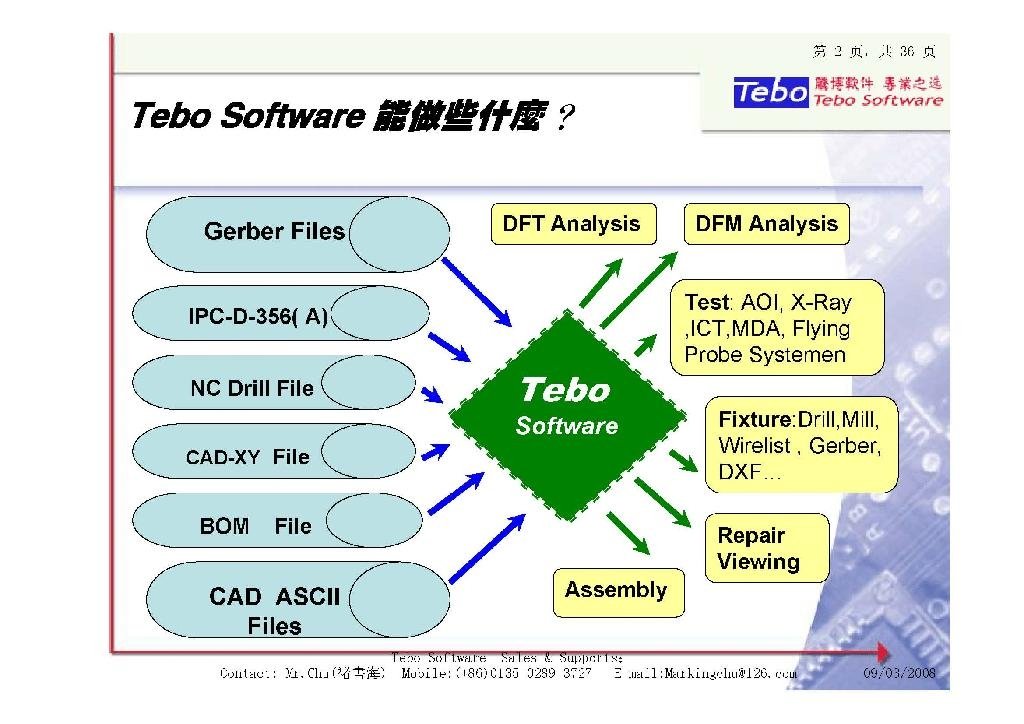

Tebo-ICT is a kind of very professional ICT and ATE fixture software. Chinese interface, designed in humanity, compatible with Win98/2000/NT/XP system, which is easy to operate and train. It can cope with all kinds of GERBER and buried via, positive and negative board materials; at the same time, it equip with many kind of CAD connector, which make it can easy to deal with data in short time. It is the best choice to make high density, complex ICT and ATE test fixture.

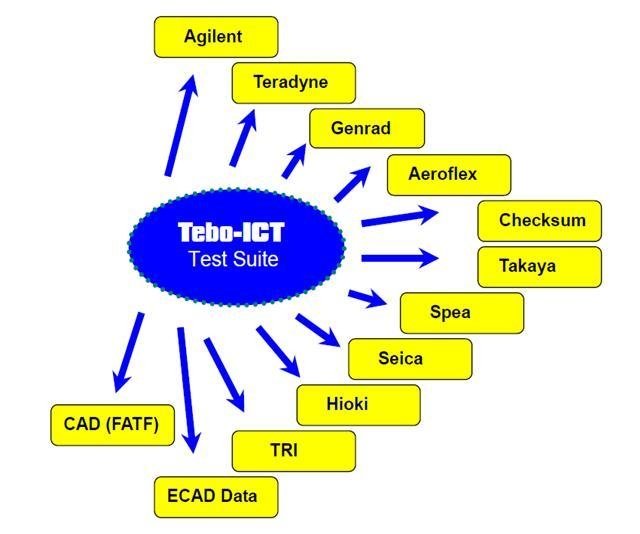

Tebo-ICT software translates your CAD or GERBER files into real reference designators, netlists, X/Y component pin geometries, values, tolerances, part numbers, etc. Also Gerber to Seica Flying Probe IPC-D-356 file. This data is then used by Test Engineers to program their ATE (Genrad ".ckt", Teradyne "ipl", Hewlett Packard "board & board x/y"), MDA, and flying probe test equipment (Takaya, Seica,Spea, etc.) and design the "Bed of Nails" test fixtures.

Tebo-ICT software helps reduce time and errors in developing your test programs and test fixture (Bed of Nails). Tebo-ICT is a cost effective solution for making your job easier and saving your company money. Tebo-ICT receives its input by importing virtually any CAD and Bill Of Materials (BOM). Import files from Gerber, Mentor Graphics, PADS, OrCAD, Protel, Accel PCAD, Allegro, Cadence, Cadstar, etc. Tebo-ICT also imports standards such as IPC-D-356, GENCAD, ODB++ ,Fabmaster, etc. Tebo-ICT supports most popular In-circuit ATE and MDA, Also supports Boundary Scan (BST), Automatic X-Ray(AXI), Automatic Optical (AOI) and Flying Probe (FPT) test and inspection systems.

Tebo-ICT function characteristic:

Tebo-ICT function characteristic:1. May input each kind of form Gerber data, does not study the components to carry on the point sort, makes the fast quoted price. May input Gerber Rs274D, Gerber Rs274X, DPF, data and so on HPGL;

2. May the direct input CAD data, even more save the time. Supports the CAD connection: ODB++ (* tar, * tgz, * zip), GenCAD (* cad), Cadence (* cad), Fab FATF (* asc, * fat, * fab), Mentor (* neu), PADS (* asc), PowerPCB (* asc), Redac CADIF (* paf), Protel (* pcb) ,Undat(*.uni),Zuken (*.ftf ,*.pcf) and so on.

3. Test datas read-in reference function. Reads in Pin, Parts, the Nails files, may refer to the original measuring point serial number, the components, foot position Yuan information, the network comparison, the network name.

4. IPC 356/356A data read-in reference function. The Gerber material does not need to study the definition components name and the foot position serial number, inputs IPC 356/356A data to carry on the reference network, the components (foot position) the information function.

5. Many kinds of test orders output connection may supply the choice or ordering. Avoids mistake which artificially processes transforms creates, greatly enhances the accuracy and the working efficiency. * Vacuum (ATE) test machine: (3070,i5000,i1000),GENRAD (228X), TERADYNE (Z18XX, SPECTRUM), AEROFLEX (4,200), TRI (8,001) and so on; Vacuum (ATE) tester: * Ordinary type test machine: TRI (51.8/5001 million), JET (2.00/3 million), TAKAYA (AT3200/3400), TESCON (piont-55/66, FOCUS-2000), OKANO (FA-931, AT-01), SRC (3,001, 6,001) and so on; * Flies the needle test test machine: TAKAYA (APT-9000/9400), SPEA (4,040) and so on; * AOI automatic optics examination machine: AGILENT (SP50/SP2), ORBOTECH (VT-9000) and so on;

6. May produce exhaustive Yi Cexing to report. Including PCB basic information; analysis information; Network test information; Components cover information; Marking pin size and distributed information; May to not be possible to plant the needle reason to carry on the classification, the arrangement explanation, provides accurate reasonable test point LAYOUT for the design.

7. May from subscribe each kind of auxiliary hole type and the demonstration shape (color) marks. May produce the exhaustive needed materials (the needle Index hole Presses stick The filling piece hole and so on) reported that, facilitates the preparation corresponding material and the cost accounting.

8. Provides the many kinds of needles database to satisfy the different test and the request, but automatically acts according to the measuring point in the position to distinguish the definition measures head and size.

9. Automatic scans, components name reference function. Each kind of seal module for example: SOT23, SOIC, QFP, BGA, PLCC, 45 ??(slanting foot QFP) and so on automatic study arrangement foot position (Pin) serial number function.

10. Intellectualized automatic functions. overlapping inspection; Marking size automatic control; Double needle different color code; Line background demonstration; Segment edition marking shifting.

11. Fast convenient writing (Chinese) joins with the edition function. May carry on the printing and the reverse printing in each edition contact surface; Outputs the DXF/GERBER form chart the function.

12. Convenient BOM processing input function. May refer to the components value, on the lower limit, the attribute description, the components highly and so on the information read-in.

13. Unique DRC rule establishment and inspection function. Whether each kind of components do have the value; The value unit is whether correct; Whether the components foot does have the needle and so on; The wrong report may link the quick look.

14. Automatic increase presses the good function. May according to the components , the components highly, press the good type, the mesh spacing and so on the balanced automatic increase.

15. Outputs Mill (* NC, * OUT and so on) formula function. May (enlarge value) according to the components and highly automatically produces the mill level to the components; But automatically synthesizes with highly overlaps (overlapping) the mill shape ; May carry on the edition to each mill shape (increase/duplication/revision/deletion); May choose the cutting tool diameter, automatically produces (does not contain irregular shape) the mill shape cutting tool way.

16. Maintenance stations software Tebo-ICTView output. But the selectivity outputs each line; May establish the jurisdiction password; But note correlation explanation.

Tebo-ICT function characteristic:

Tebo-ICT function characteristic: