| Model: | - |

|---|---|

| Brand: | huake |

| Origin: | Made In China |

| Category: | Arts Crafts / Sculptures |

| Label: | screen printer , hot stamping machine , Heat transfer machin |

| Price: |

-

|

| Min. Order: | 1 pc |

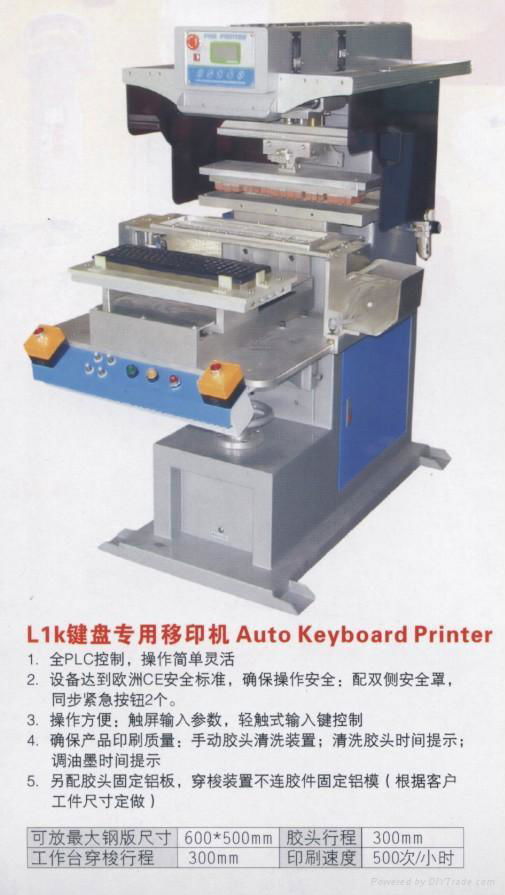

Product Description

Feature:

1. Microcomputer control with self programming; customer can set operation procedure

according to requirement.

2. S, M, L series machine with head lift bar to lift up the machine head, easy to change ink,

pad, plate and spare parts with bigger space.

3. Ink tray and pad can be changed easily to be multi colors printing, more flexible than normal

machine.

4. The ink tray/cup independent base can be adjusted X, Y direction, easy to set up multi colors

registration and improve product efficiency.

5. Conveyor machines installed with hot air dryer to ensure the ink to be dry when fast printing.

6. Ink cup machine:

6.1 Unique ink cup design with cover, easy to add ink and solvent.

6.2 Simple ink cup structure, easy to clean.

6.3 Ink cup fixed with rack, easy to install the ink cup.

7. Good quality Japan and European pneumatic parts. Metal parts CNC processed, precise

and fine finished.

8. Famous axletree with good quality, resistance to abrasion and long life.

9. Machine installed with safety guard and emergency stop to be CE standard.

Parameter:

according to requirement.

2. S, M, L series machine with head lift bar to lift up the machine head, easy to change ink,

pad, plate and spare parts with bigger space.

3. Ink tray and pad can be changed easily to be multi colors printing, more flexible than normal

machine.

4. The ink tray/cup independent base can be adjusted X, Y direction, easy to set up multi colors

registration and improve product efficiency.

5. Conveyor machines installed with hot air dryer to ensure the ink to be dry when fast printing.

6. Ink cup machine:

6.1 Unique ink cup design with cover, easy to add ink and solvent.

6.2 Simple ink cup structure, easy to clean.

6.3 Ink cup fixed with rack, easy to install the ink cup.

7. Good quality Japan and European pneumatic parts. Metal parts CNC processed, precise

and fine finished.

8. Famous axletree with good quality, resistance to abrasion and long life.

9. Machine installed with safety guard and emergency stop to be CE standard.

Parameter:

| Parameter \ Item | Single color ink tray/cup pad printer |

| Standard plate size(mm) | 100*150/100*250 |

| Max.plate size(mm) | 350*150/150*300 |

| Standard ink cup diameter | **/90 |

| Ink cup diameter optional(mm) | **/60 120 |

| Printing speed:pcs/hr | 1600 |

| Measurement(mm) | 720*550*1380 |

| Net.weight(kgs) | 100 |

| Power | 110/220v 50/60HZ |

| Air consumption(bar) | 5-7 |

Member Information

| Huake printing machines company limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 86-0769-85698000 |

| Contact: | Weiwei Xie (Manager) |

| Last Online: | 15 Jun, 2013 |