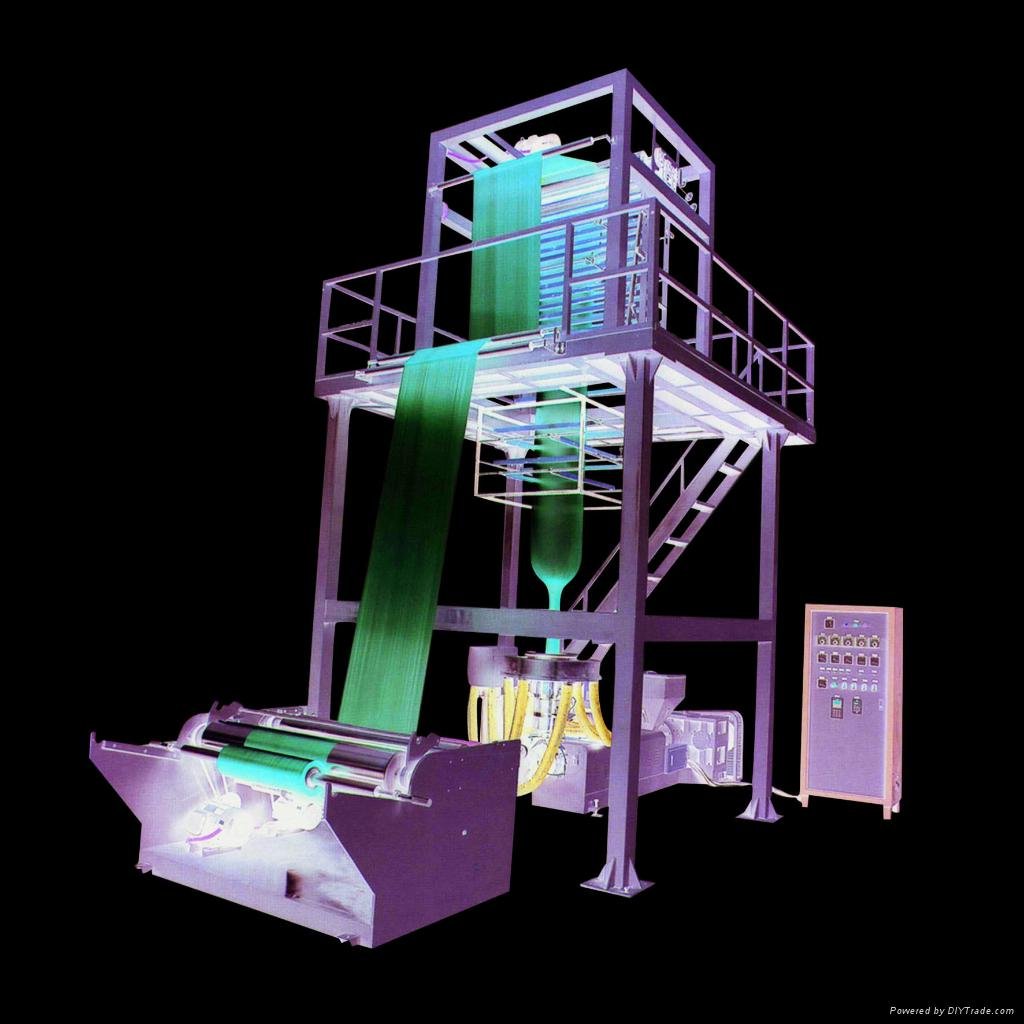

It employs some new technologies like the most advanced heat running technology and special wind ring that is used to extrude the shaped mulch plastic film. The machine is designed reasonably and elegantly. It is small and is easy to operate and maintain. The product features with good plasticization, high physical and mechanical performance and strong tear resistance. With advanced technology and reasonable accessories, the machine is featured by high output, low energy consumption, good stability and reliability etc. Therefore, it is the ideal equipment to agricultural mulch plastic film in the new century.

| Model No. |

SJ65-FMS1500N |

SJ75-FMS1700N |

SJ90-FMS2000N |

| Layer |

single |

| Max.Film Width(mm) |

LD |

1400 |

1600 |

1900 |

| HD |

1300 |

1500 |

1800 |

| Film Thickness(mm) |

LD |

0.020 ~ 0.20 |

0.020 ~ 0.25 |

| HD |

0.015 ~ 0.12 |

0.020 ~ 0.15 |

0.020 ~ 0.20 |

| Output(kg/h) |

LD |

80 |

90 |

110 |

| HD |

70 |

80 |

90 |

| Raw Material |

HDPE、LDPE、LLDPE |

| Extruder |

| Screw Diameter |

mm |

Φ65 |

Φ75 |

Φ90 |

| Screw L/D |

30:1 |

28:1 |

25:1 |

| Heater Capacity |

kw |

16.5 |

20.7 |

24.4 |

| Driving Motor |

kw |

30 |

37 |

45 |

| Die(rotating die is optional) |

| Die Diameter |

mm |

LDPE:Φ350 |

LDPE:Φ400 |

LDPE:Φ500 |

| (LD/HD free choice) |

HDPE:Φ90、Φ120 |

HDPE:Φ110、Φ150 |

HDPE:Φ125、Φ175 |

| Heater Capacity(KW) |

LD |

9.95 |

11.35 |

14.3 |

| HD |

6.1 |

6.8 |

| Cooling Air Blower |

kw |

4 |

5.5 |

| extruder |

| Haul-off |

kw |

2.2 |

| Take-up Speed |

m/min |

10 ~ 50 |

| Winder Drive Motor |

kw |

4.4 |

6.6 |

| Temperature Control |

Zone |

6 |

7 |

| whole power |

kw |

~ 70 |

~ 84 |

~ 100 |

| Shape Size |

m |

6.7 X 3.2 X 5.5 |

7.3 X 3.5 X 6.0 |

8.0 X 4.0 X 7.0 |

| Weight |

t |

~ 4.5 |

~ 5.5 |

~ 7.0 |