| Model: | P2-610 |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | pad printer , pad printing machine , china pad printer |

| Price: |

US $3411

/ pic

|

| Min. Order: | 1 pic |

Product Description

|

Two colors pad printer with shuttle //Structure |

||

|

Working table |

Two stations Shuttle-type working table |

|

|

Shuttle stroke |

200mm |

|

|

Ink supply system |

Open-type inkwell system |

|

|

Plate type |

10mm Thick steel plate. |

|

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

|

Ink drying |

Heat air |

|

|

Two colors pad printer //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

Two colors pad printer with shuttle//Parameter |

||

|

Technical parameters |

P2-606 |

|

|

||

| P2-610 | P2-612 | |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certicate |

CE |

|

|

Two colors pad printer with shuttle//Advantage |

||

|

Function |

|

|

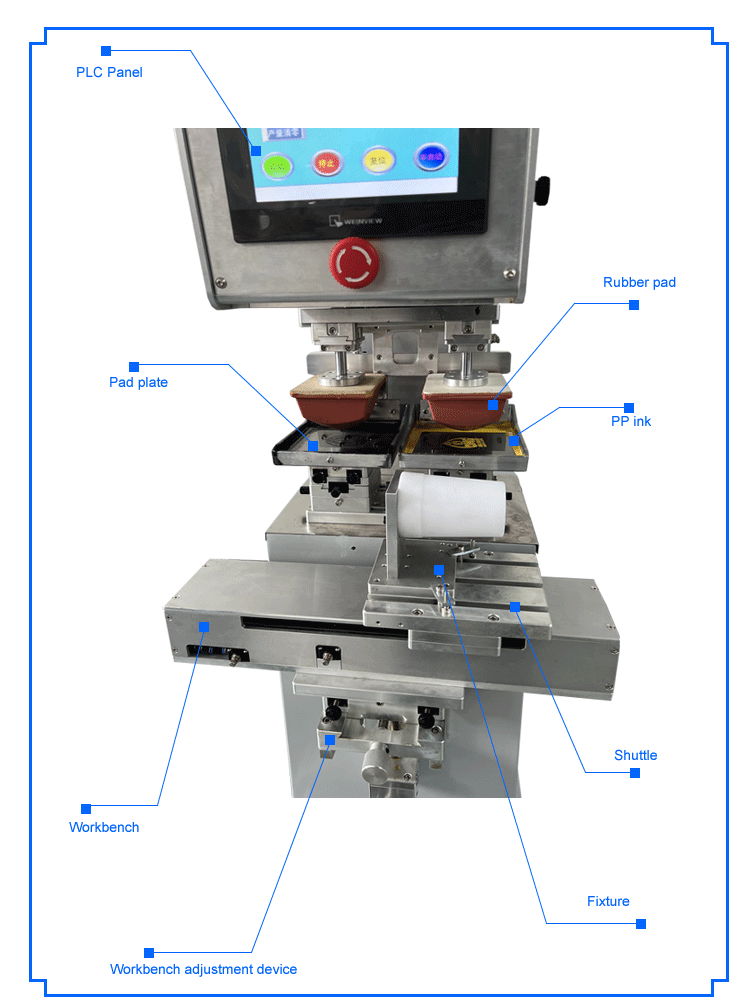

| Application: | This is a two-color shuttle pad printing machine with a steel plate with a width of 150mm, and the area of printed products has been greatly improved. With the man-machine dialogue operation interface, the control performance of the machine is better. With two-color shuttle structure, precise two-color overprinting can be realized. Using Mitsubishi PLC and imported pneumatic components, the life of the machine has been significantly improved. |

|---|---|

| Base structure: | Two-color shuttle pad printers are generally composed of the following parts: 1) Workbench: The workbench can be adjusted up and down, left and right, front and back, and angle to ensure that the pad printing position meets user needs. The shuttle table of the workbench can be controlled by pneumatic or servo motor. 2) Operation panel: The operation panel is used to control the movement of the entire pad printer. Simpler pad printers are controlled by microcomputers, and complex pad printers are controlled by PLC and touch screen. 3) Ink supply system: It is the place where ink is placed. There are two structures on the market, one is an open oil pan structure, and the other is a closed oil cup structure. 4) Pad printing system: It is a device that transfers ink to the product. It is composed of one or more sets of rubber head devices. The rubber head device changes position on the printing plate and the product. Its movement can be controlled by pneumatic or servo motor. 5) Power source: Most pad printers are driven by pneumatic components, so air compressors are required to provide compressed air. There are also pure electric pad printers on the market that do not require compressed air. 6) Additional devices: In order to continuously improve the printing quality of the pad printer and reduce the labor intensity of the operator, the pad printer will also be equipped with a pre-press device, a pad cleaning device, a drying device, a positioning sensor and a safety grating. |

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 22 Nov, 2024 |

Related Products of this Company

-

Marker pen lipstick Pen-rod heat

US $9971

-

High accurate servo pad printing machine

US $11800

-

Shoe heel automatic pad printing machine

US $12500

-

Two colors pad printer with shuttle

US $5863

-

Cosmetic automatic hot foil stamping

US $22000

-

Sports equipment Hydraulic hot stamping

US $4853

-

Full automatically 8 colors T shirt

US $27481

-

Tabletop hot stamping machine(HT-TC822)

US $2764

-

Safety-type hot stamping

US $8676

-

Automatical two colors Ball screen

US $13800