| Model: | SM12-5050 |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | slik printer , screen machine , screen printer |

| Price: |

US $4411

/ pic

|

| Min. Order: | 1 pic |

Product Description

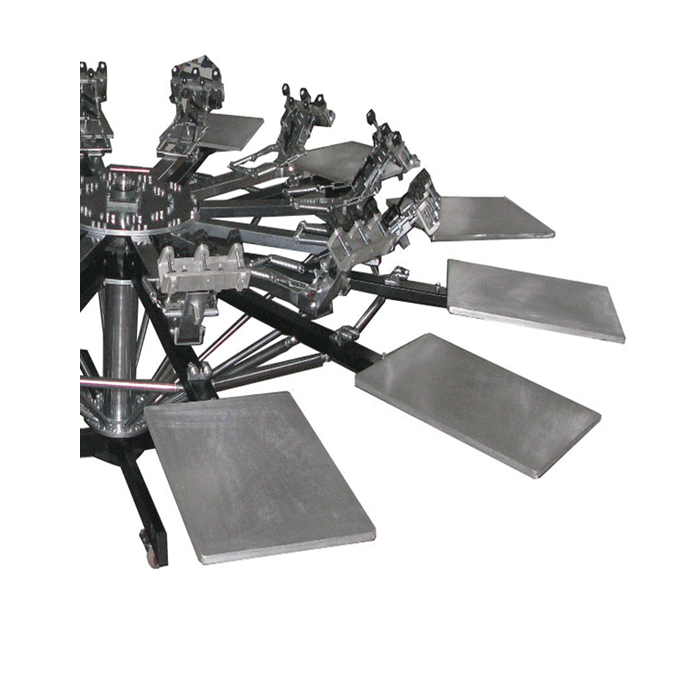

The manual screen printing machine can do up to 12 colors. The more colors, the more difficult it is to manufacture the machine. 12 screen plates and 12 worktables rotate around a central axis, which has higher strength and overprinting accuracy of the machine. Therefore, the structure of the machine must be strong, and the design must be reasonable. Since it is manual operation, the rotation flexibility of the screen rotation and the worktable must be good, which is a requirement to reduce the labor intensity of the operator. Precision grinding of seamless steel pipes, high-strength support rods, brand-name bearings, strict assembly procedures and inspection procedures will ensure that the 12-color screen printing machine can print on the T-shirts perfectly.

Octopus T-shirt screen printing machine:

Structural features

• All-steel structure: The whole machine body is made of all-steel structure, which has strong firmness and stability. It can effectively reduce the shaking of the machine during the printing operation, ensure the accuracy of printing, and is very durable. It can be used for a long time without deformation and other problems.

• Aluminum workbench: The workbench is made of aluminum material, which is light and has good flatness. It is convenient to place printed items such as T-shirts, and is easy to clean and maintain, which helps to create a good operating plane for printing.

• Octopus design: It is called "octopus" because it has multiple flexibly adjustable parts or support structures, similar to the tentacles of octopus. For example, multiple adjustable printing head fixing devices or positioning fixtures can assist and control the printing process from different angles and directions, increasing the flexibility and diversity of printing.

Working principle

It works based on the basic principles of screen printing. First, make the designed pattern into a screen printing plate, place the ink on one end of the printing plate, and then push the ink on the printing plate with a scraper, so that the ink passes through the mesh with the image on the printing plate and transfers to the surface of the T-shirt placed on the aluminum workbench, thereby forming the required pattern.

Performance advantages

• High printing quality: Thanks to the stable all-steel structure and the flat aluminum workbench, as well as the reasonable octopus-style layout to control the printing process, it can print high-quality patterns with clear patterns, bright colors and precise positions on T-shirts, meeting the situation with high requirements for printing quality.

• Strong flexibility: Multiple adjustable parts are convenient for corresponding adjustments according to different sizes and styles of T-shirts, and can also change the printing angle, position and other parameters according to different pattern designs and printing requirements, so as to achieve a variety of printing effects.

Applicable scenarios

It is mainly used in the field of T-shirt customization, such as personalized T-shirt customization stores, small clothing studios, etc., to provide reliable printing equipment to meet customers' personalized printing needs for patterns, texts, etc. It can also be used for printing and production of some cultural activities, team customized T-shirts and other occasions.

|

SM12-5050 Manual 12-color garment screen printing machine//Structure |

|

|

Working table |

High strength cast aluminum plate -500*500mm |

|

Actions |

Rotating working table and rotating screen plate |

|

To be printed |

|

|

Rotating angle |

30 |

|

Squeegee and screen plate control |

High precision rotating disc |

|

Ink drying |

Heat set ink, IR Drying |

|

SM12-5050 Manual 12-color Garment screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

|

|

SM12-5050 Manual 12-color garment screen printing Machine //Parameters |

|

|

Technical parameters |

SM12-5050T 12-colour Manual-operating rotating flat screen printing machine

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

|

SM12-5050 Manual 12-color garment screen printing machine//Advantage |

|

|

Function |

|

| Application: | There are many structures of screen printers, but you will find that the structure of screen printers for printing clothing pieces is very different from that of screen printers for printing plastic, paper, glass and other products. Screen printers for fabric pieces are usually designed in a form where the screen and printing head rotate around the central axis, similar to an octopus. We call this type of screen printer an octopus screen printer. 1) The workbench generally uses a flat aluminum plate, on which glue can be applied during printing. The glue can bond the clothing pieces to the workbench to prevent movement; 2) The screen and workbench of a manual screen printer will rotate around the central axis to achieve multi-color screen printing. The automatic screen printing machine table keeps rotating to achieve multi-color screen printing; 3) The printing device generally adopts front and back scraping printing, which makes it easier to place products, check products, and achieve multi-color accurate overprinting; 4) A swing drying device is usually set between printing stations to facilitate the drying of the ink layer and prevent the next color printing from causing ink color bleeding; 5) The drying device on the screen printing machine often only dries the ink layer on the surface and dries it thoroughly. A separate tunnel drying furnace can be used for drying, which can improve production efficiency. Screen printing machines face fierce competition from printers. Printers have developed rapidly due to the lack of complex processes such as plate making and color matching, but they are still difficult to compare with screen printing machines in terms of three-dimensional patterns and bright colors with very strong surface power. They play a powerful role in clothing printing in the market. |

|---|---|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 12 Dec, 2024 |

Related Products of this Company

-

Embossment Hydraulic hot stamping

US $11470

-

Drone shell High accurate servo pad

US $11800

-

Easy operation Flat Precision screen

US $7150

-

Pneumatic Flat screen printer with

US $2647

-

Electronic cigarette Two colours pad

US $13000

-

Electrical appliance Pad printer with

US $3236

-

Safety-type hot stamping machine

US $8676

-

Flat/cylinder hot stamping machine

US $3969

-

Seals Automatic Numbering hot stamping

US $21000

-

Automatically one color pad printer for

US $9500