| Model: | SKYF |

|---|---|

| Brand: | SIHAI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Solders |

| Label: | Turning and Shifting |

| Price: |

-

|

| Min. Order: | - |

Product Description

|

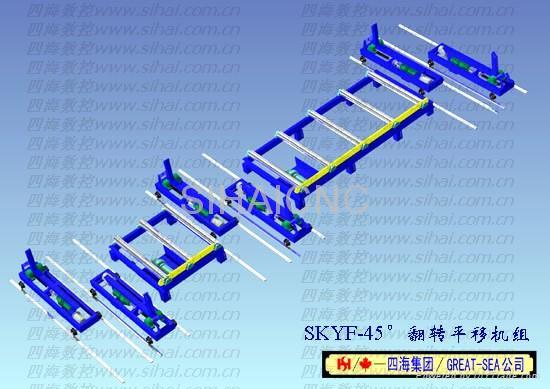

SKYF-45 ° Turning and

|

|

|

In order to secure the welding quality, the 45 ° turning and shifting machine is equipped on NC tangling arm welding machine ( graph 1), which and secure the quality of welding as well as harmonized operation. 45 ° turning and shifting machine is a necessary in H Steel welding and line atomization. This equipment adopts manual or remote control, has complete mechanic structure. It takes less space, has huge strength, and turns steadily and swiftly without noise. It takes upper space and coordinate with the whole line well. II. Machine part SKYF-45 ° turning and shifting machine adopts mechanic structure. It is consist of horizontal traveler. • Turning frame: Turning frame is a right angle body installed in horizontal base. The turning action of 45 ° is completed by cooperation of retarder, gear and rack. Horizontal movement is controlled by worm wheel retarder. • Horizontal traveler: Horizontal movement is controlled by worm wheel retarder. Press remote control button when needed. The welding line of H steel will be placed under tangling arm welding machine's head. The worm wheel retarder is locked; and traveler can not move in order to secure the quality of welding. Keeping and Spare parts • Study manual before operation

III. Electronic control system • Main electronic parts are famous brand with high quality and reliable feature.

Environment demand • Working temperature: 0-50 degree

|

|

90 ° turning and shifting machine is mainly applied in turning H steel in 90 ° or 180 ° , with simple structure. It can replace crane and be operated steadily (graph 1).

This equipment adopts manual or remote control, has complete mechanic structure. It takes less space, has huge strength, and turns steadily and swiftly without noise. It takes upper space and coordinate with the whole line well.

Machine part

90 ° turning and shifting machine adopts mechanic structure. Turning frame is installed in horizontal base, and takes less space. The turning action is completed by cooperation of retarder, gear and rack. Horizontal movement is controlled by worm wheel retarder. (gear and rack)

• Turning frame: Turning frame is a right angle body installed in horizontal base. The turning action is completed by cooperation of retarder, gear and rack. Horizontal movement is controlled by worm wheel retarder.

• Horizontal traveler: Horizontal movement is controlled by worm wheel retarder.

Press remote control button when needed. The welding line of H steel will be placed under tangling arm welding machine's head. The worm wheel retarder is locked; and traveler can not move in order to secure the quality of welding.

Keeping and Spare parts

• Study manual before operation

• Checking insulator regularly

• Clean track and remove stuff

• No entering when operating

• Oiling retarder before operation

IV. Electronic control system

• Main electronic parts are famous brand with high quality and reliable feature.

• Protection against short circuit and overload

• Function of moving to left and right.

• Function of turning left and right.

• Innovative remote control

• Turning and shifting signification

• Restrict position

Environment demand

• Working temperature: 0-50 degree

• Storing temperature: -20-60 degree

• Storing humidity: 5-95%, no moisture

• Strike resistance finger: 10G accelerated strikes (11mesc, continuously)

• EMI: through FCC/CE Class A

• AC3 working manner

Member Information

| Harbin Sihai CNC Group | |

|---|---|

| Country/Region: | Hei Long jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 86 013946108109 |

| Contact: | Gao Ying (Sales Manager) |

| Last Online: | 25 Mar, 2014 |