Printing water glue

Product Name: MF silk screen, no glue

Type number: MF-3311

Specifications: 3KG/ barrel (12KG/ case), 5KG/ barrel, 20KG/ barrel

Features: high and low temperature type screen printed pressure-sensitive adhesive, heat cold, moisture resistance. Excellent performance; water dispersible adhesive, no harmful gas combustion, convenient storage; no ink and substrate impact and corrosion; high solid content over a large area.

1) excellent bonding properties for metals and plastics (ABS, PC, PVC, PMMA, etc.)

2) excellent resistance to heat and moisture;

3) non corrosive to ink and other materials. No organic solvent, good for environment and health, and safe operation;

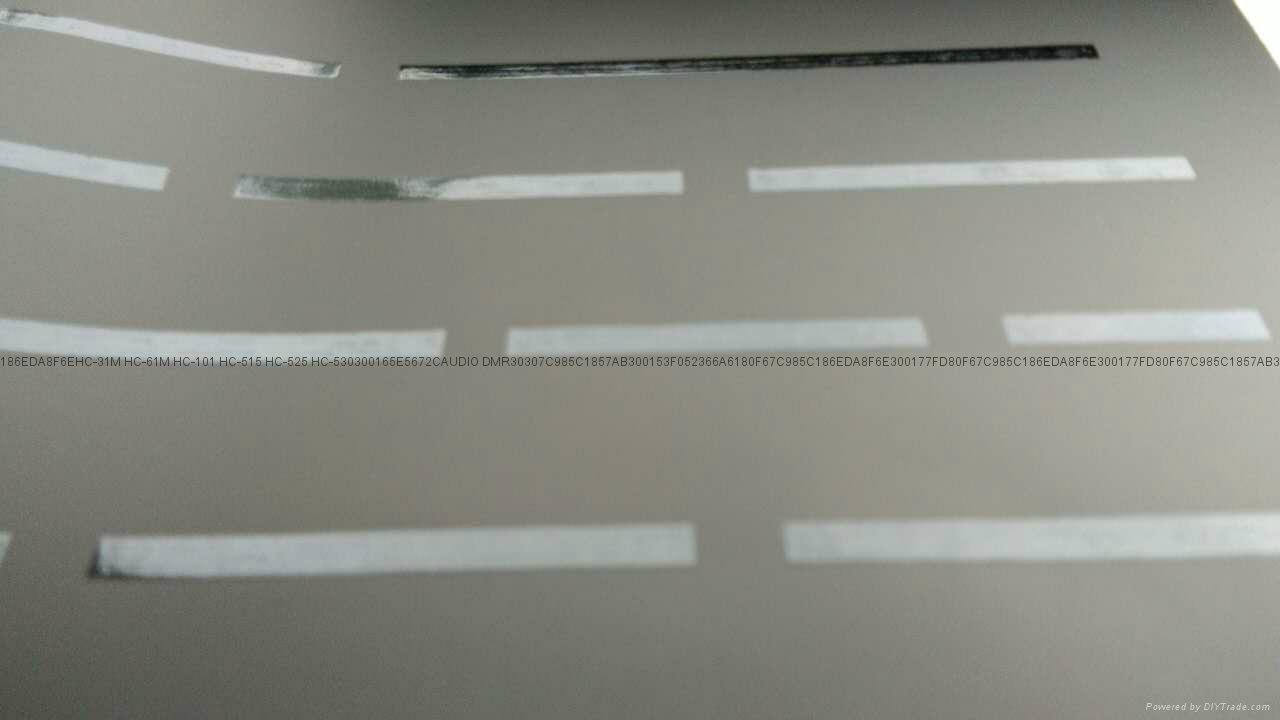

4) excellent printing operation performance, can print exquisite patterns, can be full printed, can be printed strip, dot and non-standard pattern;

5) high performance, low cost, can replace double-sided adhesive tape

Main ingredients:

Usage: MF-3311 silk screen adhesive is a pressure-sensitive adhesive for screen printing with high adhesion, temperature resistance and water resistance. It is widely used in electronic products, household electrical appliances and automobile industry

Guide to use:

1) equipment: semi-automatic or manual screen printing machine can be;

2) mesh: 80-120 mesh polyester mesh and stainless steel, mesh tension: 14-18

3) scraper: hardness is 60-70 degrees, polyurethane material, scraping angle: 60-80 degrees;

4) drying conditions: 25 degrees -30 minutes, 60 degrees -15 minutes, 80 degrees -5 minutes

Product application:

1) electronic, electrical, home appliances and automotive panels, nameplates, and panels with window panels and fixed panels with irregular surfaces;

2) all kinds of membrane switches;

3) coated with foam and rubber noise reduction slow shock material

4) bonding plastic and stainless steel, aluminum and other metal panels

5) SMT patch bonding

6) self-adhesive coating