| Model: | 2209 |

|---|---|

| Brand: | GH |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Cutter & Tongs |

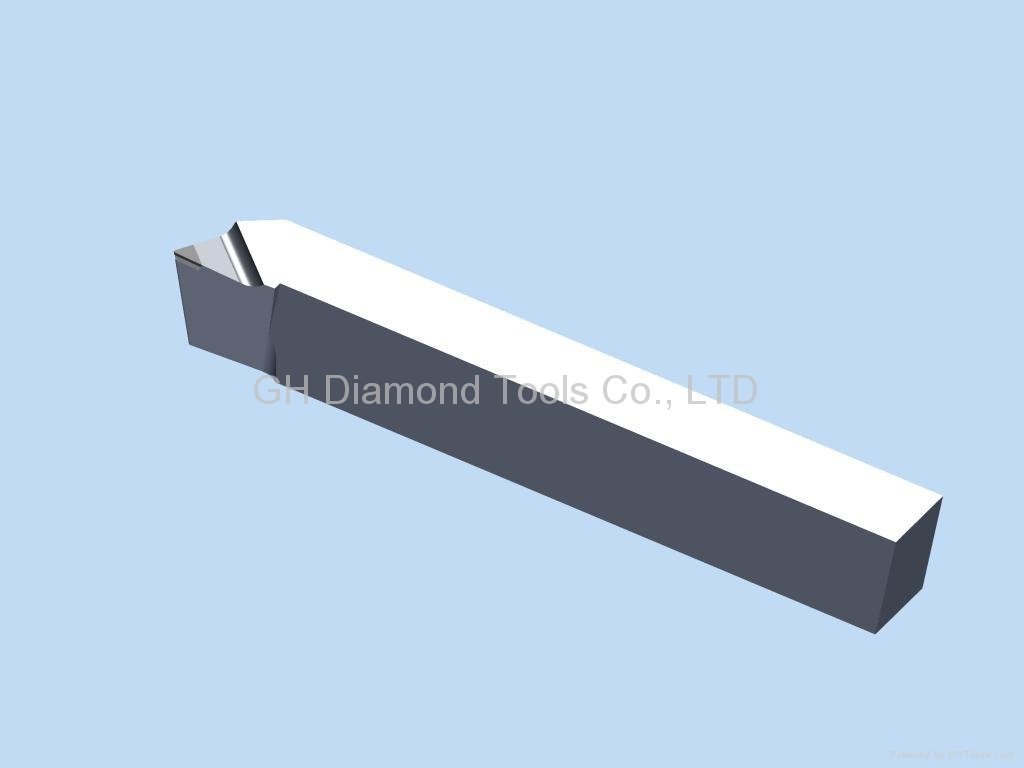

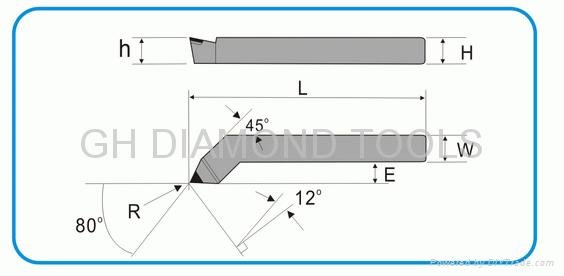

| Label: | PCD turning tools , diamond turning tool , PCD TOOLS |

| Price: |

-

|

| Min. Order: | 2 pc |

Product Description

PCD-Turning and Milling Tools

PCD is a synthesised, extremely tough, intergrown mass of randomly orientated diamond particles in a metal matrix. It is produced by sintering together selected diamond particles at high pressure and temperature.

Poly-crystalline diamond (PCD) is used in many cutting operations as a substitute for mono-crystalline diamonds (MCD). Its advantages are in the interrupted cut and in cases of extreme wedge angle geometry. The correct type of PCD for the respective task, polished cut surfaces and the finest ground cutting edges are important characteristics of our tools.

PCD tool range on the one hand includes drills, milling cutters and reamers as well as ISO-Indexable inserts.

The examples of Machining with PCD Cutting Tools

Application:10~11%Si Turning of engine piston (aluminum alloy containing Si)

Cutting Speed /Feed Rate/Depth of Cut :328m/min 0.13mm/rev 0.10~0.15mm

Results:Tool life is 3 times than using natural single crystal diamond

Application:Milling of contacting surface of aluminum inhale tube

Cutting Speed /Feed Rate/Depth of Cut :460m/min,2.34m/min(0.25mm/ tooth ),0.25mm

Tool life: 89,000 pcs/chip, 14 times than using tungsten carbide

Member Information

| GH Diamond tools Co.,Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 57456199 |

| Contact: | GAVEN (Market Manager) |

| Last Online: | 25 Jan, 2024 |

Related Products of this Company

-

Diamond woodworking tools cove box bit

US $45

-

Jewelry Diamond Pneumatic Nail Needle

US $17

-

CNC Mini Internal Grooving boring tool

US $6

-

Carbide scribing tool Plastic Glass

US $3.4

-

PCD CBN Full Face Round insert RNMN RNGN

US $23.5

-

Glass scribing wheel holders

US $50

-

Jewelry making tools V MCD Diamond

US $23

-

small hole Diamond bore cutter PCD

US $14.8

-

Glass scribing wheels tool Glass

US $3.4

-

PCD wood cutter Diamond V Profile router

US $60