| Model: | METRICE INCH |

|---|---|

| Brand: | Vlier,BERG,de-sta-co,nordex,Reid,MISUM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Fastener & Fitting |

| Label: | Spring Plungers , ball Plungers , Plungers |

| Price: |

-

|

| Min. Order: | 50 pcs |

Product Description

Spring Plungers

Spring Plunger tips made by most manufacturers,are case hardened. This means they have a protective shell, about .10" deep.Beneath this shallow veneer is mild, untreated steel. The our plungers are fabricated from hardened steel.our Spring and Ball Plungers have accurate end forces, are easy to install, and are competitively priced. They are manufactured in the U.S.A. in a ISO 9001 certified quality system.And if these aren’t enough reasons to specify

our Spring and Ball Plungers, here are a few more:

Better Point of Contact

The our plungers are turned and the tips generated in one smooth continuing process. This results in a constant radius tip, perfectly tangent to the point where the tip joins the shaft. Conventional two step, turn and grind operations,can leave ridges on the shaft at the tip junction and can also produce out-of-round tips.These,in turn, can gouge or score finely finished parts or can cause detent cams to hang up or stick.

Extra Length Springs for Longer Life

The longer the spring, the longer its life.our goes to extra lengths to minimize the thickness of the base flanges on all of its plungers. That allows us to use longer springs with less chance for fatigue and breakage.

Improved Plunger to Body Alignment

The long base flange allows for a larger bearing surface. This means improved plunger-to-body alignment, truer travel, and much improved side load characteristics.

Tighter Fit Resists Contamination

Closer machining tolerances, minimum plunger-to-body clearance, and smoother plunger finish make our plungers fit more snugly in the plunger bore. This improves plunger alignment and provides extra resistance to contaminant entry. The results: dirt and grit cannot get to the bearing surfaces to shorten the life of the plunger.

Better Plunger Adjustment

The Solid Drive?design assures that during removal or adjustment of the plunger,the whole plunger is moving, not just the set screw. This means no lost parts or springs falling out of the plunger.

Product specifications:

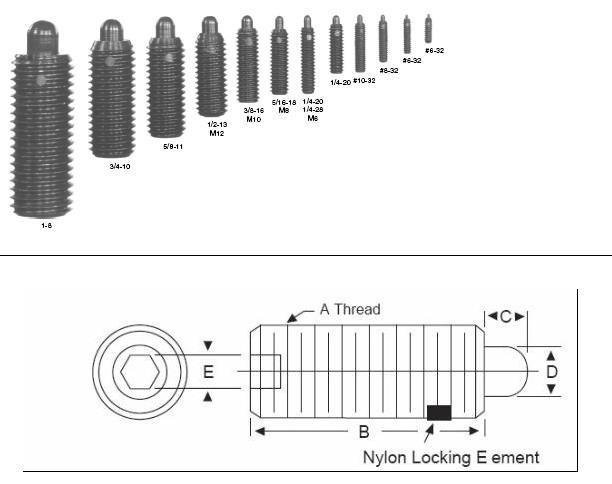

The first type specification: long, short.

Stretch levels: light and heavy.

point material: SCM435, SUS304, Nylon 66.

Plunger head material: S45C, SUS440, SUJ2, ceramics, resin, polyacetal, fast cutting of copper.

Thread Specifications:

Metric: M4 * 0.4, M5 * 0.8, M6 * 1.0, M8 * 1.25, M10 * 1.5, M12 * 1.75, M16 * 2.0, M20 * 2.5

Inch :6-32, 6-40, 8-32, 8-36, 10-32,1 / 4-20, 5/16-18, 3/8-16, 1/2-13, 5/8- 11, 3/4-10, 1-8

Spring Plunger tips made by most manufacturers,are case hardened. This means they have a protective shell, about .10" deep.Beneath this shallow veneer is mild, untreated steel. The our plungers are fabricated from hardened steel.our Spring and Ball Plungers have accurate end forces, are easy to install, and are competitively priced. They are manufactured in the U.S.A. in a ISO 9001 certified quality system.And if these aren’t enough reasons to specify

our Spring and Ball Plungers, here are a few more:

Better Point of Contact

The our plungers are turned and the tips generated in one smooth continuing process. This results in a constant radius tip, perfectly tangent to the point where the tip joins the shaft. Conventional two step, turn and grind operations,can leave ridges on the shaft at the tip junction and can also produce out-of-round tips.These,in turn, can gouge or score finely finished parts or can cause detent cams to hang up or stick.

Extra Length Springs for Longer Life

The longer the spring, the longer its life.our goes to extra lengths to minimize the thickness of the base flanges on all of its plungers. That allows us to use longer springs with less chance for fatigue and breakage.

Improved Plunger to Body Alignment

The long base flange allows for a larger bearing surface. This means improved plunger-to-body alignment, truer travel, and much improved side load characteristics.

Tighter Fit Resists Contamination

Closer machining tolerances, minimum plunger-to-body clearance, and smoother plunger finish make our plungers fit more snugly in the plunger bore. This improves plunger alignment and provides extra resistance to contaminant entry. The results: dirt and grit cannot get to the bearing surfaces to shorten the life of the plunger.

Better Plunger Adjustment

The Solid Drive?design assures that during removal or adjustment of the plunger,the whole plunger is moving, not just the set screw. This means no lost parts or springs falling out of the plunger.

Product specifications:

The first type specification: long, short.

Stretch levels: light and heavy.

point material: SCM435, SUS304, Nylon 66.

Plunger head material: S45C, SUS440, SUJ2, ceramics, resin, polyacetal, fast cutting of copper.

Thread Specifications:

Metric: M4 * 0.4, M5 * 0.8, M6 * 1.0, M8 * 1.25, M10 * 1.5, M12 * 1.75, M16 * 2.0, M20 * 2.5

Inch :6-32, 6-40, 8-32, 8-36, 10-32,1 / 4-20, 5/16-18, 3/8-16, 1/2-13, 5/8- 11, 3/4-10, 1-8

Member Information

| suzhou rongyuan co.,ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 13862082630 |

| Contact: | RICO.XU (G.E.) |

| Last Online: | 07 Dec, 2016 |