| Model: | KX/HIG |

|---|---|

| Brand: | HIG |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | Wear resistant steel , Abrasion resistant , Wear resistant blade |

| Price: |

US $400

/ m

|

| Min. Order: | 2 m |

Product Description

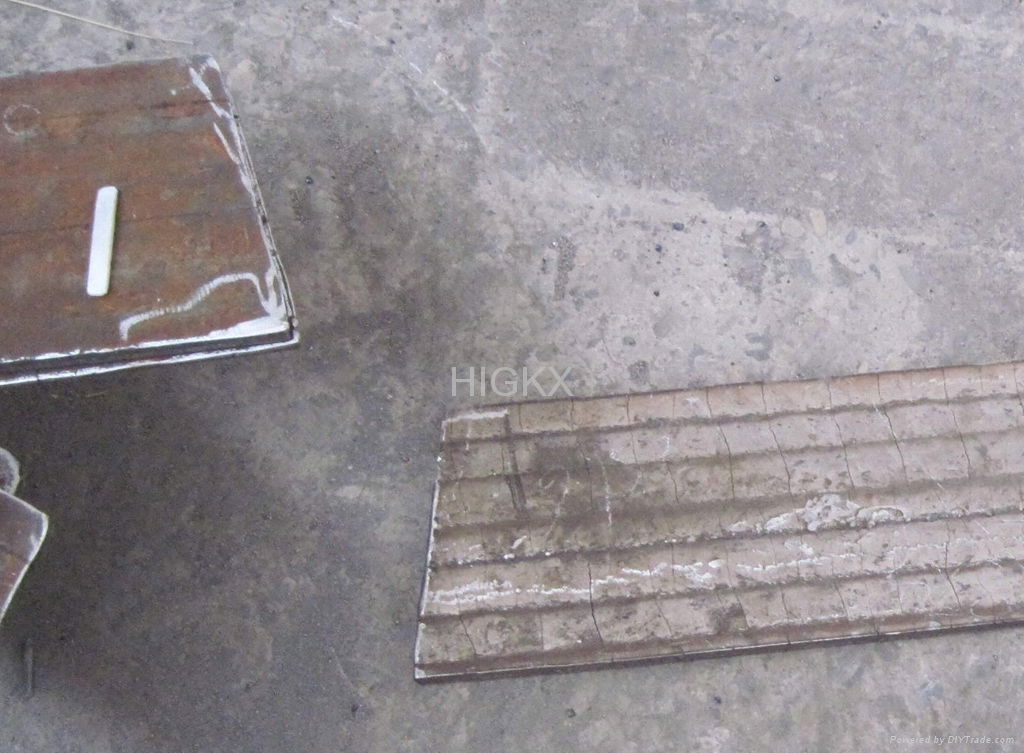

High Wear Resistant steel plate

High abrasion resistant steel plate

We main produce the wear resistant steel plate which is made from alloy materials and welding materials hard-facing on the low carbon steel. The thickness of weld deposit is up to 4 mm ~15mm including the Carbon, Chromium and other alloys composition. The wear resistant layer has the excellent metallurgic bonding between the weld metal and the base plate.

As the abrasion resistant materials, The WR plate have good wear resistance property and it is better than other steel plate including the high manganese steel and wear resistant cast iron and cast steel. The steel plate is used in the field of high impact abrasion workshop as the wear liner and the wear plate. The Wear Resistant plate is widely used for the Mining equipments, Cement industry, Power plant, Crusher parts, coal crusher and Port handling system. The welding metal have good machining property for the cold forming and rebuilding the Wear parts, Mixer parts, transfer Chute, Hopper, Bucket, Loader, wear plate. Also, the WR plate is easy to cutting and welding processing in the common work shop.

Specification of Wear Resistant steel plate:

Product Brand: KX / HG

Thickness of base steel plate: 6mm ~ 15mm;

Thickness of wear resistant Layer (Weld Deposit ): 4mm ~ 15mm;

Surface Hardness (HRC): 54 ~ 62 HRC;

Wear resistant plate dimension (W*L): 1500mm * 2000 / 6000mm;

We can design the special wear resistant steel plate according to the customer’s requirements and engineering drawing. Our products will help you to make different shape wear resistant parts easily through the cold forming processing, cutting and welding in your workshop.

Usage advantage of Wear resistant steel plate:

----- Decreasing the maintenance cost of equipments.

----- Improve the equipment operation rate.

---- Reduce the energy consumption of mill equipments.

---- Decreasing the environmental pollution for the leakage scrap from the worn out plate and reduce the cost of labor for keeping the clean in the plant. .

Application:

Cement industry:

Feeder equipment, Wind blade and lining, Crusher lining, excavator grab, Mill lining, Body of pump, Worm conveyer, Bunker, Chute, powder concentrator blade.

Power plant: Coal Mill Lining, Clinker, coal crusher, Charging Bucket,

Coal mining: Chute lining plate, Bunker, Chute, Lining for coal crusher,

Other application: Mixer parts, Mould of brick, Coke transfer chute, Port Handling system, Mining machine ceiling, Grab, fitting and Elbow.

Member Information

| HIGENERAL NEW MATERIALS CO., LTD | |

|---|---|

| Country/Region: | Gui Zhou - China |

| Business Nature: | Trading Company |

| Phone: | 13595120059 |

| Contact: | Yang Ronghai (salesman) |

| Last Online: | 02 Jun, 2019 |