The application of high temperature damping technology in aerospace industry is increasing day by day, and some of its applications are very successful. The problems related to the stability of large spacecraft, engine vibration, noise control and noise control in aircraft cabin are the application of high temperature damping technology. In view of the fact that the vibration and noise inside the cockpit are too large under special circumstances, airlines and aircraft manufacturers pay more and more attention to the acoustic environment inside the cockpit. How to reduce the noise in the cockpit and improve the ride comfort of the aircraft has become one of the hot issues in aircraft research. Noise in aircraft cabin mainly comes from structural sound and air sound. In the control of noise in aircraft cabin, the medium and high frequency air noise can be effectively isolated by laying sound insulation cotton and other sound insulation materials to improve airtightness of the fuselage. However, the medium and low frequency noise caused by engine vibration decreases little with distance in the structure and is difficult to suppress. System. Especially for aircraft design, the weight and space are strictly controlled. Low and medium frequency noise has always been a difficult problem in aircraft cabin noise control.

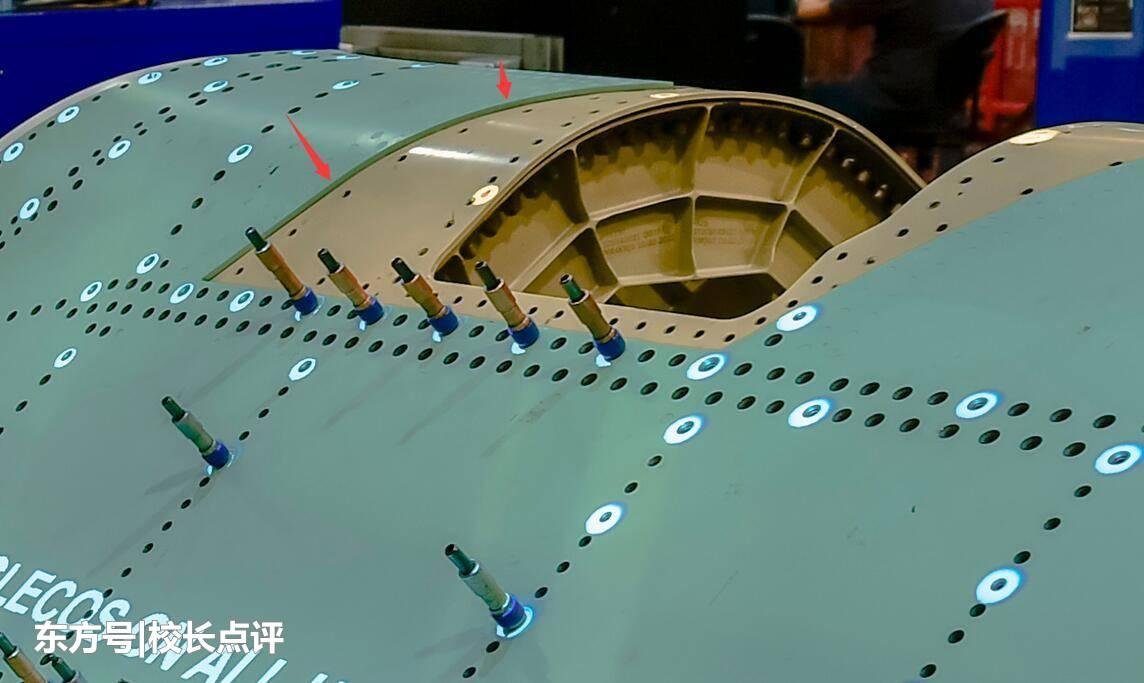

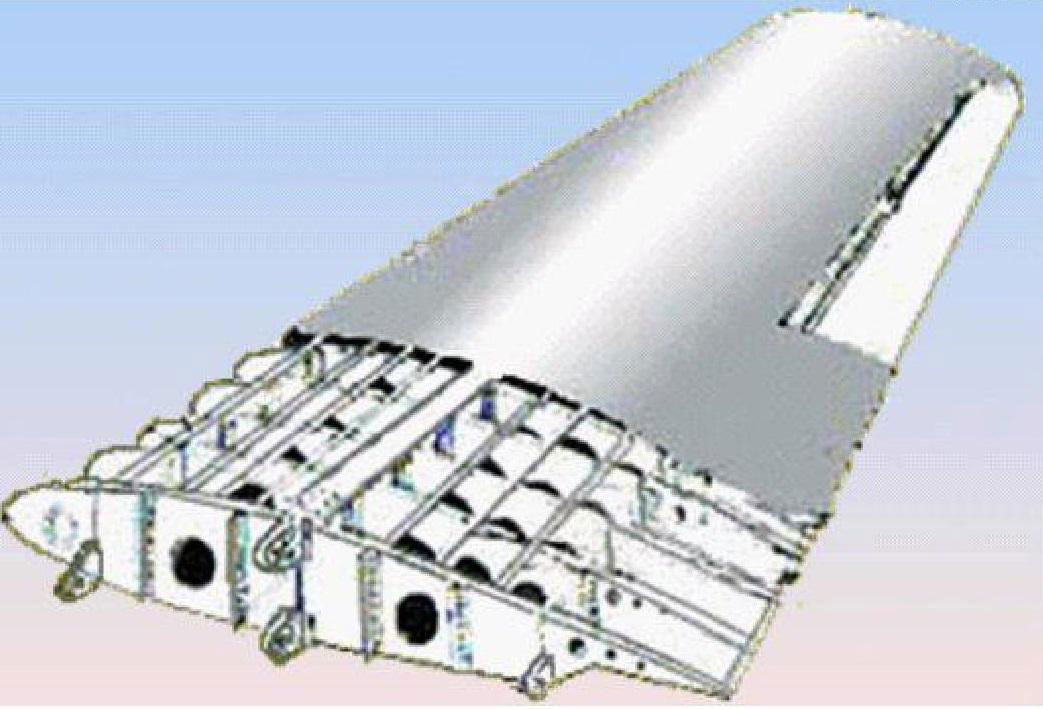

Polymer restrained damper (high temperature and low temperature strengthening patch) material is an effective measure to reduce vibration and noise of thin-walled structures. The restrained damper layer is laid on the vibration-sounding thin-walled plates, which can improve the noise reduction ability and reduce radiated noise by restraining the amplitude of bending vibration. Constrained Damping Layer (High Temperature and Low Temperature Reinforcement Patch) has broad prospects and applications in automotive, subway, ship and aerospace industries.