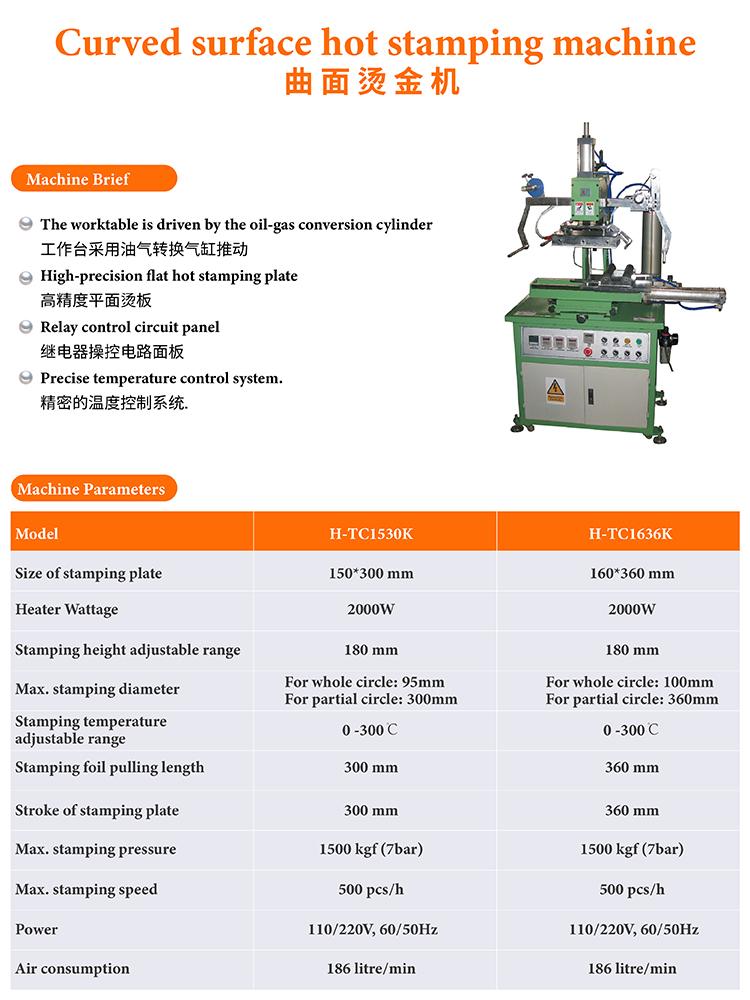

| Model: | H-TC1636K |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | hot stamper , hot stamping machine , hot foil stamping |

| Price: |

US $4382

/ pic

|

| Min. Order: | 1 pic |

Product Description

Hot stamping on cylindrical products such as bottle caps, cups, hoses, bottles and other products requires a curved surface stamping machine. The workbench of the curved surface stamping machine adopts the shuttle movement method to drive the product to rotate at a constant speed. The ironing plate of the curved surface stamping machine adopts a flat ironing plate, which can be installed with copper plates, zinc plates, and silica gel plates. When the ironing plate is pressed down, the stamping paper will be tightened. Pressed tightly on the surface of the product, the rolling process of the product will form a bronzing pattern in the circumferential direction.

There are many types of curved surface hot stamping machines according to the diameter of the hot stamping product. The larger the size of the hot plate, the larger the diameter of the hot stamping product. Most of the curved surface stamping machines are driven by cylinders to move the shuttle table, and hot stamping machines with higher requirements use oil-gas conversion cylinders to drive the movement of the shuttle table. The speed of curved surface stamping machines is generally slow, and the market oil for automated curved surface stamping machines has increased significantly in recent years.

|

H-TC1636K Pneumatic Flat-cylinder hot stamping Machine//Structure |

||

|

Working table |

Shuttle working table, Max stamping diameter: 100mm |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of Stamping head |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Stamping plate size |

160*360mm. |

|

|

H-TC1636K Pneumatic cylinder hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-TC1636K Pneumatic cylinder hot stamping Machine //Parameter |

||

|

Technical parameters |

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-TC1636K Pneumatic cylinder hot stamping machine //Advantage |

||

|

Function |

|

|

| Application: | Hot stamping on cylindrical products such as bottle caps, cups, hoses, bottles and other products requires a curved surface stamping machine. The workbench of the curved surface stamping machine adopts the shuttle movement method to drive the product to rotate at a constant speed. The ironing plate of the curved surface stamping machine adopts a flat ironing plate, which can be installed with copper plates, zinc plates, and silica gel plates. When the ironing plate is pressed down, the stamping paper will be tightened. Pressed tightly on the surface of the product, the rolling process of the product will form a bronzing pattern in the circumferential direction. There are many types of curved surface hot stamping machines according to the diameter of the hot stamping product. The larger the size of the hot plate, the larger the diameter of the hot stamping product. Most of the curved surface stamping machines are driven by cylinders to move the shuttle table, and hot stamping machines with higher requirements use oil-gas conversion cylinders to drive the movement of the shuttle table. The speed of curved surface stamping machines is generally slow, and the market oil for automated curved surface stamping machines has increased significantly in recent years. |

|---|---|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 18 Sep, 2024 |

Related Products of this Company

-

Servo Cylinder hot stamping

US $12880

-

Plastics components hot stamping

US $3594

-

Leather paper plastics 4 tons pressure

US $1300

-

light fittings Hot stamping

US $2441

-

Cost-effective hot selling Paper hot

US $2441

-

Package case hot stamping

US $2912

-

Easy operation safety style Plastics

US $2294

-

large format Book cover hot stamping

US $3059

-

Bottle cap hot stamping

US $3459

-

Manual Hot stamping machine-HM-TC1927

US $1200