| Model: | H-TC4060LPN |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | hot stamping machine , gilding machine , bronzing machine |

| Price: |

US $8970

/ pic

|

| Min. Order: | 1 pic |

Product Description

There will be huge pressure when the hot plate and the worktable are in contact, which is a potential safety hazard for all hot stamping machines. In order to improve the safety of the hot stamping machine, you can install a safety door, install a safety grating, and use a two-button operation mode. Another important practice is to set the workbench to enter and exit automatically. The workbench enters and exits automatically, which can facilitate the pick-and-place of the product and avoid the safety failure of the operator.

The automatic entry and exit of the workbench is also convenient for the operator to observe the product placement, which is more conducive to product positioning. The complete solution to the safety problem of the semi-automatic plane hot stamping machine is to use a fully automatic hot stamping machine, that is, automatic feeding, automatic hot stamping, and automatic unloading, which completely eliminates the possibility of the operator touching the hot plate and the workbench. However, during the deb ing process of the machine, this kind of contact is still unavoidable, and it is necessary to carry out the necessary safety training for the operator.

|

H-TC4060LPN Pneumatic move-table hot stamping Machine//Structure |

||

|

Working table |

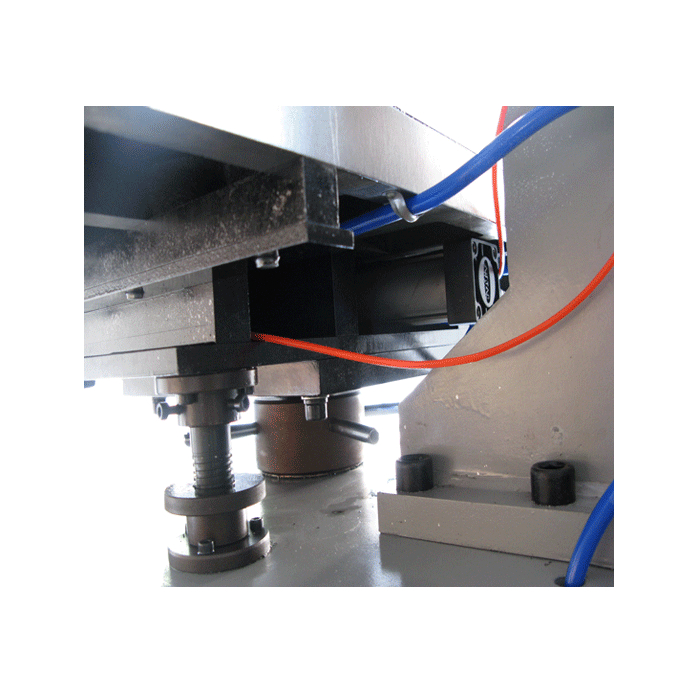

High strength Steel plate , size: 520*800mm. automatically in-out |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Stamping plate size |

400*600mm. |

|

|

H-TC4060LPN Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-TC4060LPN Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC4050LPN Pneumatic hot stamping Machine with movement table

|

H-TC4060LPN Pneumatic hot stamping Machine with movement table

1. Hot plate area:400×600 mm 2. Working table area:800 ×520mm 3. Max printing pressure:15,000 Kg 4. Up and down distance:70mm 5. Heat wattage: 6×800W 6. Foil in feed: Motor Drive 7. Temperature adjustment:0-300oC 。 |

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-TC4060LPN Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|

| Updated : | 220V/110V/50HZ/60HZ/1-Phase |

|---|---|

| Application: | There will be huge pressure when the hot plate and the worktable are in contact, which is a potential safety hazard for all hot stamping machines. In order to improve the safety of the hot stamping machine, you can install a safety door, install a safety grating, and use a two-button operation mode. Another important practice is to set the workbench to enter and exit automatically. The workbench enters and exits automatically, which can facilitate the pick-and-place of the product and avoid the safety failure of the operator. The automatic entry and exit of the workbench is also convenient for the operator to observe the product placement, which is more conducive to product positioning. The complete solution to the safety problem of the semi-automatic plane hot stamping machine is to use a fully automatic hot stamping machine, that is, automatic feeding, automatic hot stamping, and automatic unloading, which completely eliminates the possibility of the operator touching the hot plate and the workbench. However, during the deb ing process of the machine, this kind of contact is still unavoidable, and it is necessary to carry out the necessary safety training for the operator. |

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 14 Nov, 2024 |

Related Products of this Company

-

Mask UV disfection machine

US $2073

-

Tabletop UV Curing Unit

US $1250

-

Cylinder hot stamping machine(H-TC1636K)

US $4382

-

UV& IR screen printing machine

US $14118

-

Auto trademark Hot stamping

US $2588

-

Cost-effective hot selling Paper hot

US $2441

-

Hot stamping machine with two sets foil

US $9200

-

TV frame Hot stamping machine(H-TC1520N)

US $2147

-

Spot UV Flat UV Curing Machine for paper

US $2129

-

Manual large size Hot stamping machine

US $1618