| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Industrial Supplies / Mining Machine |

| Label: | Caustic calcined mag , Calcined magnesia , Magnesite calcinatio |

| Price: |

-

|

| Min. Order: | - |

Product Description

Calcined magnesite Introduction:

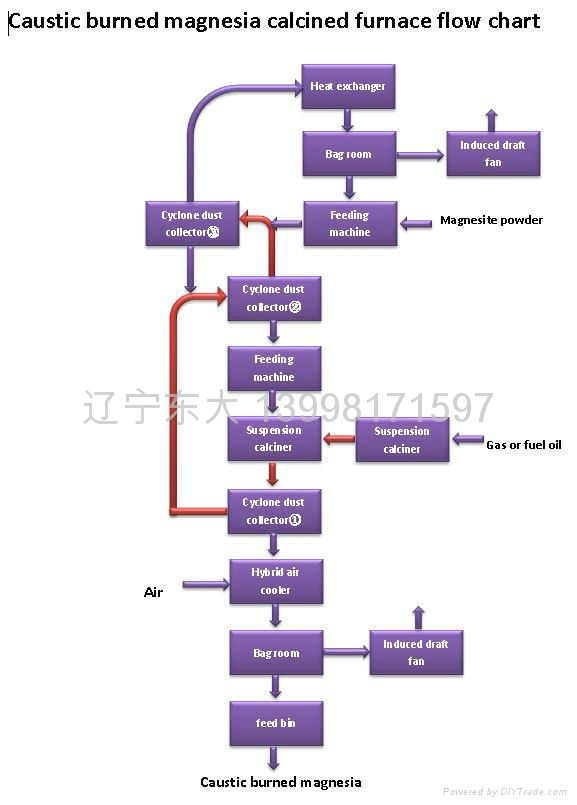

· Calcination of magnesite introduction: · are vertical kiln calcination of magnesite traditional methods or in the rotary kiln. Shaft kiln and is a massive stone of magnesite calcination in rotary kiln, with a long burning time, burning is not homogeneity, influence product activity, as well as environmental pollution and wastage of resources. Powder dynamic calcination furnaces to resolve the current problems in burning. Name: dynamic calcining furnace is hot air through crushing of calcined magnesite powder on a furnace. Mainly consists of preheating and drying, heat exchangers, calcined decomposing furnace, catcher, heat and so on. Material into the furnace after a short time you can achieve rapid decomposition. Since it is a powdered calcined magnesite materials, stone of magnesite powder float in the calciner, each tiny dust quickly heated, calcined materials evenly, there is no burning and burning, burning temperature can be accurately controlled. Work principle: mill good of magnesite fine powder (or filter pie of magnesite), by sent feeder into, drying machine preparatory heating magnesite fine powder, (uses calcined decomposition furnace decomposition magnesite production of more heat air to joined magnesite fine powder), after heating Hou of magnesite fine powder, into calcined furnace within calcined, decomposition Hou of MgO (light burn magnesium) entered collection manager. Features: 1. the calcined material uniform, full, production of activated magnesium oxide. 2. equipment systems and pollution-free, in line with the requirements of environmental protection. 3. thermal energy consumption compared with shaft kiln 20~30%4 savings. Easy to operate, high degree of automation. Technical specifications: series specifications within sets of production: 10,000 tons, 20,000, 50,000 tons, 100,000 tons, 150,000 tons, 200,000 tons.

· Calcination of magnesite introduction: · are vertical kiln calcination of magnesite traditional methods or in the rotary kiln. Shaft kiln and is a massive stone of magnesite calcination in rotary kiln, with a long burning time, burning is not homogeneity, influence product activity, as well as environmental pollution and wastage of resources. Powder dynamic calcination furnaces to resolve the current problems in burning. Name: dynamic calcining furnace is hot air through crushing of calcined magnesite powder on a furnace. Mainly consists of preheating and drying, heat exchangers, calcined decomposing furnace, catcher, heat and so on. Material into the furnace after a short time you can achieve rapid decomposition. Since it is a powdered calcined magnesite materials, stone of magnesite powder float in the calciner, each tiny dust quickly heated, calcined materials evenly, there is no burning and burning, burning temperature can be accurately controlled. Work principle: mill good of magnesite fine powder (or filter pie of magnesite), by sent feeder into, drying machine preparatory heating magnesite fine powder, (uses calcined decomposition furnace decomposition magnesite production of more heat air to joined magnesite fine powder), after heating Hou of magnesite fine powder, into calcined furnace within calcined, decomposition Hou of MgO (light burn magnesium) entered collection manager. Features: 1. the calcined material uniform, full, production of activated magnesium oxide. 2. equipment systems and pollution-free, in line with the requirements of environmental protection. 3. thermal energy consumption compared with shaft kiln 20~30%4 savings. Easy to operate, high degree of automation. Technical specifications: series specifications within sets of production: 10,000 tons, 20,000, 50,000 tons, 100,000 tons, 150,000 tons, 200,000 tons.

| Advantages: | Caustic calcined magnesia |

|---|---|

Member Information

| LIAONING DONGDA DRYING & CALCINATING EQUIPMENT CO., LTD. | |

|---|---|

| Country/Region: | Liao Ning - China |

| Business Nature: | Manufacturer |

| Phone: | 13998171597 |

| Contact: | Guan Yanguang (Manager) |

| Last Online: | 03 Oct, 2019 |

Related Products of this Company

-

Magnesia powder flash calcined magnesia

-

V2O5 productor de las nuevas tecnologías

-

Çinko oksit Kalsinatörlü

-

V2O5 Melting Furnace

-

V2O5 technologie nouveau producteur

-

Vanadium melting furnace

-

V2O5 Gamybos procesas

-

Vanadium powder production process

-

V2O5 tuottaja uusi teknologia

-

V2O5 المنتجة التكنولوجيا الجديدة