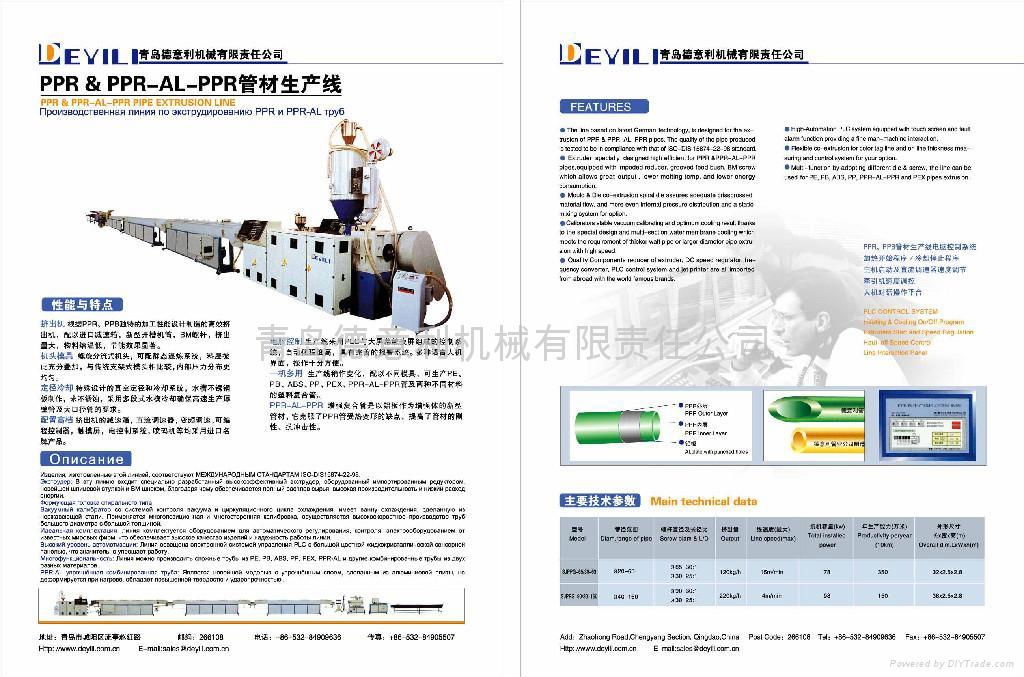

PPR/PERT/PB Pipe Extrusion line

|

Main Technical Parameter

|

|

Model

|

Pipe range

(mm)

|

Extruder

model

|

Max output

(kg/h)

|

Max hauling speed (m/min)

|

Total installed power(Kw)

|

Line length

(m)

|

|

DPPR-63

|

20-63

|

DS-65-34

|

180

|

15

|

120

|

37

|

|

DPPR-110

|

20-110

|

DS-80-34

|

280

|

8

|

220

|

39

|

|

DPPR-160

|

63-110

|

DS-80-34

|

280

|

8

|

230

|

39

|

|

Features of PPR pipe production line

1.Extruder of PPR pipe machine: specially designed for PPR pipe, equipped with imported reducer, grooved feed bush and BM screw2.Mould& Die of PPR pipe extruder: co-extrusion spiral die assures adequate crisscrossed material flow, and more even international pressure distribution with a static mixing system for option3. Calibrators of PPR tube machinery: stable vacuum calibrating and optimum cooling result thanks to the special design and multi-section water membrane cooling4.High quality components:Reducer, DC speed regulator, frequency converter, PLC control system and jet printer are all imported5.Multi-functions, a little change for the line and following with the different moulds, this line may produce PE、PB、ABS、PP、PEX、PPR-AL-PPR composite pips and so on.