| Model: | XF-002 |

|---|---|

| Brand: | Xinfei |

| Origin: | Made In China |

| Category: | Industrial Supplies / Chemical Machinery |

| Label: | multi-function wood , wood powder machine , wood flour machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

1, multi-function wood powder machine Description:

Multi-function wood flour machine is accompanied by cabinet at one end bearing spindle, the motor through the belt transmission, drive shaft and fastening the spindle rotation speed rotary knife. To rotate with the ring gear on the knife sharp teeth grinding blocks and reasonable, compact vice, so that material flow in the rotating friction and a strong close to the impact of grinding, and grinding the blade and the gaps between the blocks, make the grind again , by adjusting the material can be crushed between the head 40 mesh -325. The device is compact and reasonable structure, small size, low energy consumption, high efficiency, smooth rotation, low noise, reliable seal, no dust pollution, since the cooling function was good, easy to install, easy to dismantle easy to repair, exchange loss of convenience items. Mainly applied to saw wood flour, poplar powder, ceramics, green body black, pigments, tobacco, chemicals, pharmaceuticals, dyes, paints, pesticides, metallurgy, food, feed, plastic, plant fiber, cellulose, wood flour , reclaimed rubber and other industries to smash a low to medium hardness materials. Multi-function machine is a shell flour, corn, rice, chemicals, pharmaceutical intermediates, dyes, paints, pesticides, metallurgy, ceramics, food, fodder, non-metallic mining and scientific research enterprises, ultra-fine powder as fine powder up processing the best, most effective and most economical equipment.

Multi-function wood flour machine is accompanied by cabinet at one end bearing spindle, the motor through the belt transmission, drive shaft and fastening the spindle rotation speed rotary knife. To rotate with the ring gear on the knife sharp teeth grinding blocks and reasonable, compact vice, so that material flow in the rotating friction and a strong close to the impact of grinding, and grinding the blade and the gaps between the blocks, make the grind again , by adjusting the material can be crushed between the head 40 mesh -325. The device is compact and reasonable structure, small size, low energy consumption, high efficiency, smooth rotation, low noise, reliable seal, no dust pollution, since the cooling function was good, easy to install, easy to dismantle easy to repair, exchange loss of convenience items. Mainly applied to saw wood flour, poplar powder, ceramics, green body black, pigments, tobacco, chemicals, pharmaceuticals, dyes, paints, pesticides, metallurgy, food, feed, plastic, plant fiber, cellulose, wood flour , reclaimed rubber and other industries to smash a low to medium hardness materials. Multi-function machine is a shell flour, corn, rice, chemicals, pharmaceutical intermediates, dyes, paints, pesticides, metallurgy, ceramics, food, fodder, non-metallic mining and scientific research enterprises, ultra-fine powder as fine powder up processing the best, most effective and most economical equipment.

Second the application of multi-functional wood flour machine:

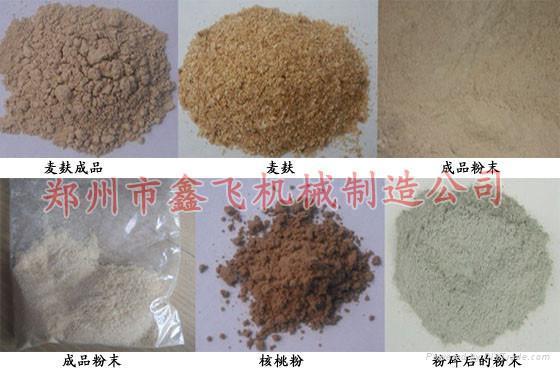

Multi-function wood flour machine is suitable for grinding the following materials: bamboo and wood powder, shell, herbs, bark, leaves, wheat bran, konjac, Ma Xuan, rice husk, corn cob, straw, starch, food type, shrimp , fish meal, shellfish, seaweed, dehydrated vegetables, hawthorn, ginger, garlic, pumpkin powder, spices, jujube, paper, circuit boards, plastic, chemical raw material, water products, spices, feed, mica, graphite, swelling soil, perlite, lees, furfural, cake, charcoal, active carbon, cellulose, potato residue, tea, hair, soybean, cotton, refined cotton, cowhide, sheepskin, plant root, stem, leaf, flower, fruit, various difficult features of hundreds of edible materials processing, chemical, building materials, medicine, health, culture, food, mosquito coils, etc. in good grinder.

Third multi-functional properties of wood powder machine features:

1, wear-resistant alloy cutting tools sharp, reliable, advanced, improve life

- Unique grinding system design, greatly enhance the service life of equipment. Crush room with multi-level process and the crushing principle of broken equipment, the impact of its work force is characterized by large, high efficiency, fine and strong.

2, the vulnerability of low consumption, low running costs

- Reasonable structure, advanced crushing principle and technical parameters, operational reliability, low operating costs; mill all the parts have wear protection, will reduce maintenance costs to a minimum, the general life can be increased by 30% and more.

Multi-function wood flour machine is suitable for grinding the following materials: bamboo and wood powder, shell, herbs, bark, leaves, wheat bran, konjac, Ma Xuan, rice husk, corn cob, straw, starch, food type, shrimp , fish meal, shellfish, seaweed, dehydrated vegetables, hawthorn, ginger, garlic, pumpkin powder, spices, jujube, paper, circuit boards, plastic, chemical raw material, water products, spices, feed, mica, graphite, swelling soil, perlite, lees, furfural, cake, charcoal, active carbon, cellulose, potato residue, tea, hair, soybean, cotton, refined cotton, cowhide, sheepskin, plant root, stem, leaf, flower, fruit, various difficult features of hundreds of edible materials processing, chemical, building materials, medicine, health, culture, food, mosquito coils, etc. in good grinder.

Third multi-functional properties of wood powder machine features:

1, wear-resistant alloy cutting tools sharp, reliable, advanced, improve life

- Unique grinding system design, greatly enhance the service life of equipment. Crush room with multi-level process and the crushing principle of broken equipment, the impact of its work force is characterized by large, high efficiency, fine and strong.

2, the vulnerability of low consumption, low running costs

- Reasonable structure, advanced crushing principle and technical parameters, operational reliability, low operating costs; mill all the parts have wear protection, will reduce maintenance costs to a minimum, the general life can be increased by 30% and more.

Fourth multi-function wood flour machine technical parameters:

|

Model

|

450

|

500

|

600

|

700

|

1000

|

|

Smashing fineness (mesh)

|

40 - 100

|

40 - 120

|

40 - 200

|

40 - 250

|

40 - 350

|

|

Production hour (kg / h)

|

30 - 150

|

40 - 200

|

50 - 220

|

70-700

|

80 - 1000

|

|

Host speed (r / min)

|

2970

|

2970

|

2970

|

2970

|

3790

|

|

Host Power (kw)

|

18.5 / 2

|

22 / 2

|

30 / 2

|

30 / 2

|

55 / 2

|

|

Fan power (kw)

|

3 / 2

|

3 / 2

|

4 / 2

|

4 / 2

|

5.5 / 2

|

|

The whole machine weight (kg)

|

1500

|

2100

|

2500

|

3100

|

3800

|

5 multi-functional wood powder machineUse and care instructions:

1.A strict test to check the machine before starting the installation meets requirements of all parts, screw bolt is loose, may try to switch hands with a light face lift, whether touching shells and so on. Also check the direction of rotation, is strictly prohibited smash flammable, explosive materials, to prevent accidents.

2.production should be maintained even under the crush material to ensure quality and normal production, while non-motor overload, in order to ensure normal operation of the machine.

3. In addition to checking the site regularly pay attention to tighten loose, the same time, it should be noted that the wear check wearing parts, such as badly worn should be replaced to avoid damage to the main components. And take the necessary fire prevention measures.

4. As the speed is higher, in addition to install correctly and securely, the same should be kept well lubricated in order to maintain the normal operation of the machine. Under normal circumstances bearing temperature does not exceed 70 degrees as normal. Once a week, plus the host bearing butter, molybdenum disulfide, high-speed butter better.

1.A strict test to check the machine before starting the installation meets requirements of all parts, screw bolt is loose, may try to switch hands with a light face lift, whether touching shells and so on. Also check the direction of rotation, is strictly prohibited smash flammable, explosive materials, to prevent accidents.

2.production should be maintained even under the crush material to ensure quality and normal production, while non-motor overload, in order to ensure normal operation of the machine.

3. In addition to checking the site regularly pay attention to tighten loose, the same time, it should be noted that the wear check wearing parts, such as badly worn should be replaced to avoid damage to the main components. And take the necessary fire prevention measures.

4. As the speed is higher, in addition to install correctly and securely, the same should be kept well lubricated in order to maintain the normal operation of the machine. Under normal circumstances bearing temperature does not exceed 70 degrees as normal. Once a week, plus the host bearing butter, molybdenum disulfide, high-speed butter better.

Member Information

| Zhengzhou xinfei machinery plant | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15938736887 |

| Contact: | zheng shiyin (manager) |

| Last Online: | 28 Feb, 2012 |