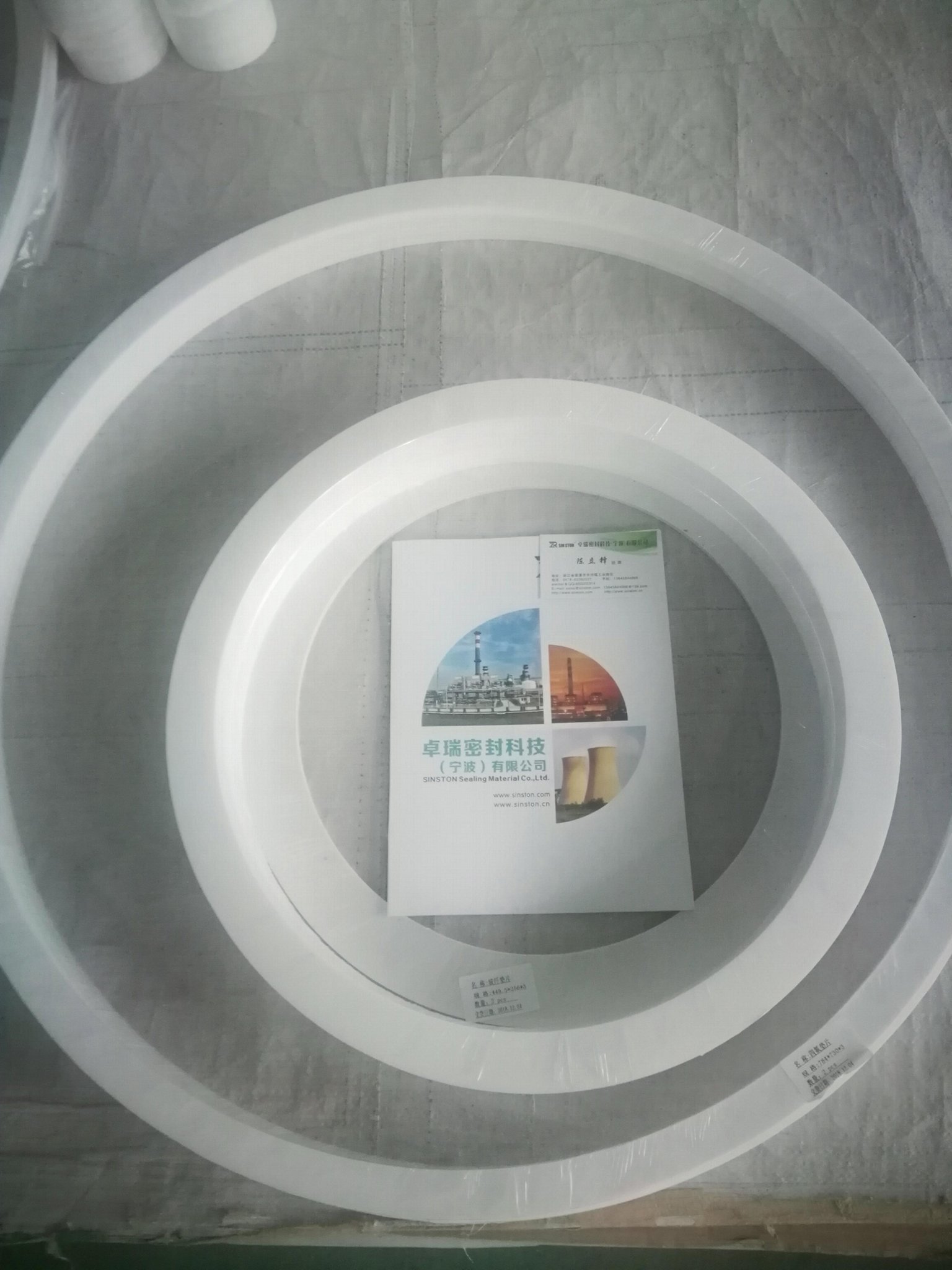

Description:PTFE Gasket is molded or skived or cut from virgin PTFE powder or compounds, sheets, rods, tube etc. It has the best chemical corrosion resistance among known plastics. Without being aging, lowest friction coefficient, wear resistance. The unloaded operating temperature range is -180~+260C.

CONSTRUCTION:

SINSTON PTFE gasket used filler materials such as glass fiber, carbon fiber and graphite etc. The filled PTFE has improved compression strength, better abrasion resistance, high thermal conductivity and lower thermal expansion compared with pure PTFE products.

Several types of PTFE gaskets are produced to meet the most demanding application.

APPLICATION:

SINSTON PTFE offers a wide range of compounded products with good mechanical properties, electrical properties, thermal properties, chemical resistance, low friction coefficient and good resistance to wear. They can be mostly used in valve seats, bearings, requested to resin sliding and chemicals, elastic band for unlubricated compressors. An extended range of improved mechanical and processing properties can be additionally reached by combination of virgin PTFE and different fillers.

Different combination offers a variety of different properties described in the following table.

|

Filler

|

Improved properties

|

|

Glass

|

Enhance wear resistance

Chemical resistance

|

|

Graphite

|

Extremely low coefficient of friction

Fairly good compressive strength

Good wear resistance

|

|

Carbon

|

Good thermal resistance

Resistance to deformation

|

|

Bronze

|

Enhanced compressive strength

Good wear resistance

High thermal conductivity

|

|