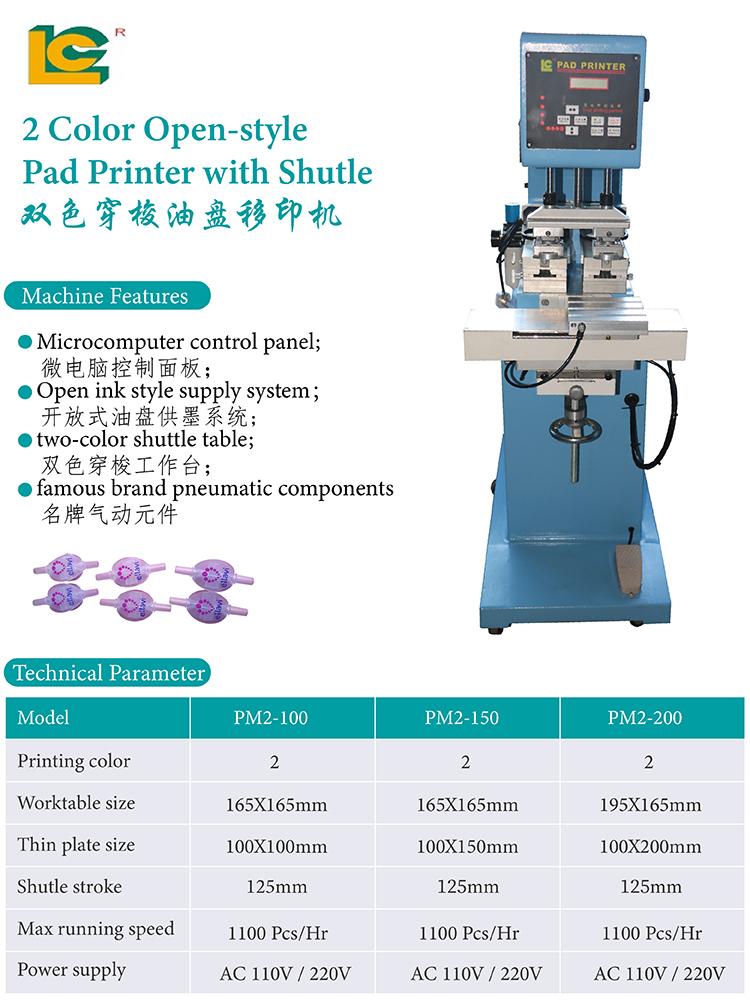

| Model: | PM2-100 |

|---|---|

| Brand: | LC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | pad press , pad printer , pad printing machine |

| Price: |

US $1750

/ pc

|

| Min. Order: | 1 pc |

Product Description

Pad printers are divided into open pad printers and closed pad printers. The open type pad printing machine first entered the market. Since the ink is exposed to the air, the volatilization of the solvent in the ink will cause discomfort to the operator's respiratory tract. Therefore, the closed type pad printing machine came into being. The oil cup placed upside down on the steel plate greatly reduces the volatilization of solvents.

Although there are certain disadvantages in open pad printers, the market for open pad printers has not shrunk by choosing harmless and low-volatile solvents. The price of open pad printers is lower, and large-size pad printers It is still difficult to replace it with closed pad printing machines. In the Asian and African markets, the sales of open pad printing machines are still considerable.

|

Two colors pad printer with shuttle//Structure |

|

|

Initial position |

Limited switch |

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Open-type inkwell system |

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

Ink drying |

Heat air |

|

Blanking |

Manual |

|

Two colors pad printer// Usage and Characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

PM2-100 |

|

|

| PM2-150 | |

|

|

| PM2-200 | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

| Summary: | Pad printers are divided into open pad printers and closed pad printers. The open type pad printing machine first entered the market. Since the ink is exposed to the air, the volatilization of the solvent in the ink will cause discomfort to the operator's respiratory tract. Therefore, the closed type pad printing machine came into being. The oil cup placed upside down on the steel plate greatly reduces the volatilization of solvents. Although there are certain disadvantages in open pad printers, the market for open pad printers has not shrunk by choosing harmless and low-volatile solvents. The price of open pad printers is lower, and large-size pad printers It is still difficult to replace it with closed pad printing machines. In the Asian and African markets, the sales of open pad printing machines are still considerable. |

|---|---|

Member Information

| LC industrial company Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Mr kelven bai (Sales Manager) |

| Last Online: | 23 Nov, 2024 |

Related Products of this Company

-

Independent pressing pad printer

US $3353

-

large size Stand pad printer(P1-612)

US $3309

-

12 colors pad printer (SP12-41030C)

US $16360

-

Pad Printing Steel plate

-

PP container Flame treatment machine

US $2235

-

Manual operating Hot stamping machine

US $1200

-

Shuttle pad printer(PM2-250LT)

US $4206

-

Conveyor pad printer SP6-40818

US $7029

-

Cloth-label two colors pad printer

US $4500

-

Film output machine for pad printing and

US $7240