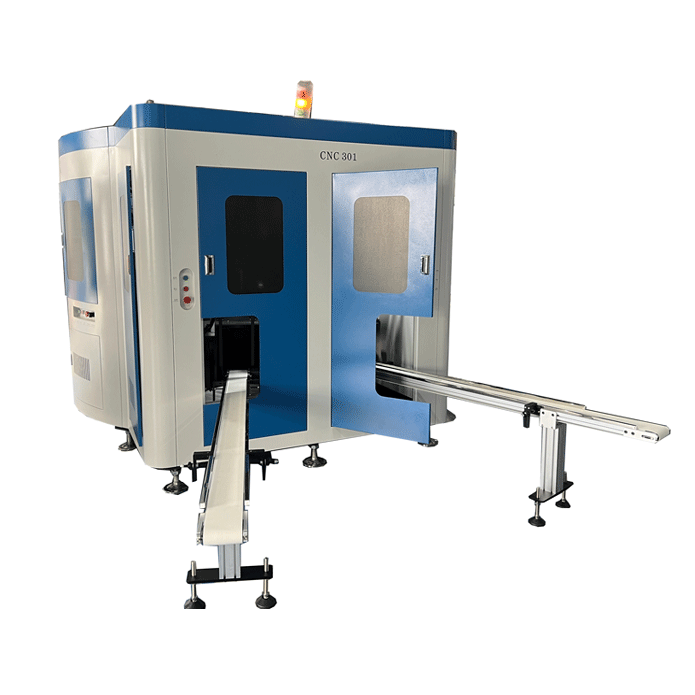

| Model: | CNC301 |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | auto screen printer , auto wine printer , auto silk printer |

| Price: |

US $66000

/ pic

|

| Min. Order: | 1 pic |

Product Description

Full servo rotating wine bottles screen printing machine

Principle

The substrate is transported to the turntable through the conveyor belt, and then positioned by CCD camera to enter the turntable clamping mechanism to ensure that the wine bottle enters the printing position correctly, and then undergoes pre-press processing, three-color screen printing and UVLED curing, and finally completes the high-precision wine bottle decoration technology.

Structure

• Conveyor belt feeding system: The glass wine bottle and other substrates are automatically transported to the printing position through the conveyor belt to improve feeding efficiency and accuracy.

• CCD positioning system: The CCD optical camera is used to capture the substrate image, and the position relationship between the screen frame and the substrate is automatically calculated and analyzed and adjusted through the industrial computer image processing technology to ensure accurate alignment of the printed pattern, such as the overprint accuracy can reach plus or minus 0.02 mm.

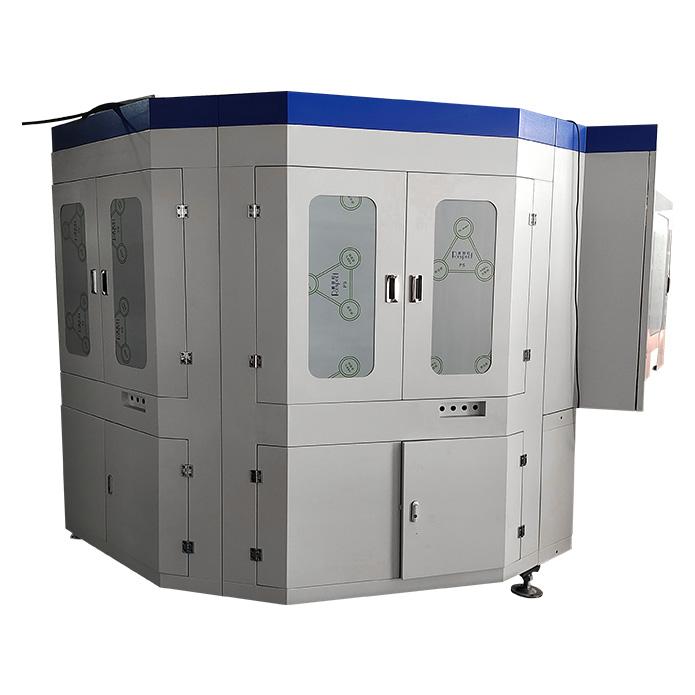

• Three-color flat turntable: It can carry and rotate the substrate to achieve multi-color printing and improve printing efficiency and quality.

• Fully automatic screen printing system: including screen printing plate, squeegee, ink supply device, etc., to complete ink transfer and pattern printing.

UVLED curing device: UVLED curing device can quickly cure UV ink, realize timely overprinting and fast delivery of multi-color printing

• Screen servo system: accurately control the position and movement of the screen, ensure the distance and angle between the screen and the substrate, and improve printing accuracy and stability.

• Automatic servo positioning system: accurately control the position of the printing table, substrate, etc., to ensure the relative position of each component during the printing process, improve printing accuracy and consistency.

Advantages

• High precision: CCD positioning, screen servo system and automatic servo positioning system work together to make the printed pattern high in alignment accuracy and accurate in size, meeting the needs of high-precision printing.

• High efficiency: conveyor belt feeding and three-color flat turntable and other devices realize automatic feeding and multi-color printing, improve production efficiency and reduce labor costs.

• Good stability: precise control and stable operation of each system, as well as advanced mechanical structure design, make the printing quality stable, the pattern clear, full, and the color uniform.

• Strong adaptability: It can be applied to glass bottles, red wine bottles, beer bottles of different shapes and sizes, and can also print various types of inks to meet the printing needs of different products.

• Easy operation: It is usually equipped with an intelligent control system, touch screen operation, and easy parameter setting, which reduces the technical requirements for operators.

Application

• Wine packaging industry: Print trademarks, patterns, texts, etc. on glass bottles, red wine bottles, and beer bottles to enhance the appearance and brand recognition of products.

• Cosmetics industry: Used for surface printing of cosmetic glass bottles and plastic bottles to increase the beauty and attractiveness of products.

• Food and beverage industry: Labels, instructions and other information can be printed on packaging containers such as beverage bottles and food cans.

• Electronics and electrical industry: Printing logos, patterns and characters on electronic product housings, circuit boards, etc.

• Household products industry: Surface decoration printing on glassware, ceramic products, furniture and other household products to meet personalized customization and diversified decoration needs.

Structure

|

Item |

Description |

STANDARD ITEMS |

Q |

|

1 |

Feeding system |

In-feeding conveyor with motor-driven |

1 |

|

|

|

Feeding robot |

1 |

|

2 |

Pre-treatment |

Flame treatment device |

1 |

|

3 |

Workbench |

1.5M rotating workbench with high accurate splitter |

1 |

|

4 |

Print system |

High accurate screen printing system |

3 |

|

|

|

Servo screen plate system |

3 |

|

|

|

Servo rotating positioning system |

3 |

|

|

|

CCD positioning system |

3 |

|

|

|

Safety cover |

1 |

|

|

|

PLC Control system |

1 |

|

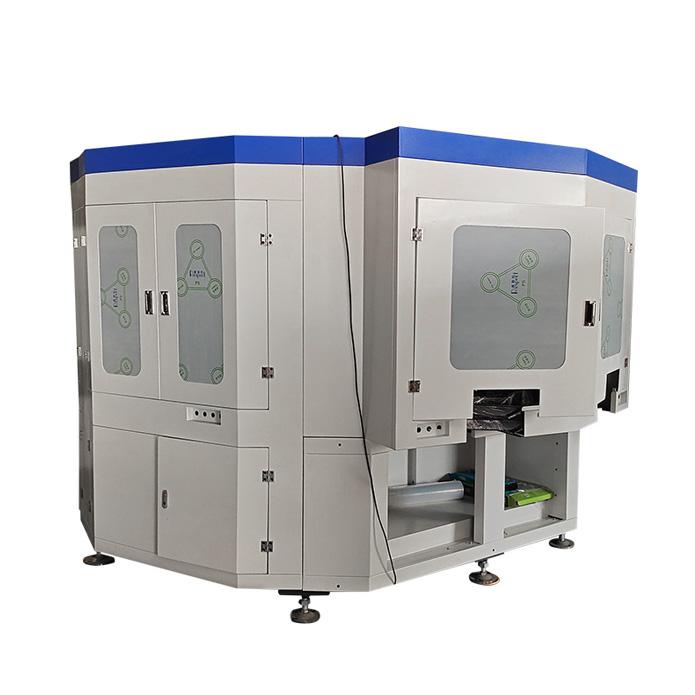

5 |

UV LED system |

UV curing system |

3 |

|

6 |

Downloading |

Downloading robot + 1.5M downloading conveyor |

1 |

Technical parameter:

|

Item |

Description |

Parameters |

|

1 |

Feeding system |

Speed : 0-10M/ |

|

|

|

Conveyor width: 50mm |

|

2 |

Pre-treatment |

Fire width: 250mm |

|

3 |

Workbench |

Rotating plate diameter : 1.5M |

|

4 |

Print system |

Max print diameter: 100mm |

|

|

|

Max print length: 300mm |

|

|

|

Screen plate up-down adjustment : 150mm |

|

|

|

Overprint accurate: 0.05-0.1mm |

|

|

|

Max print speed: 3000pcs/H |

|

|

|

Air : 5-7 bar |

|

|

|

Print color number: 3 colors |

|

|

|

Materials: plastics, glass, ceramic,. |

|

|

|

PLC Control system |

|

5 |

UV system |

UV Wattage: 4KW |

|

6 |

Downloading |

Conveyor width : 0.5M |

|

|

|

Conveyor speed: 0-10M/min |

|

7 |

Power supply |

3 P380V |

System Configuration

|

Items |

Description |

Brand |

Note |

|

1 |

Pneumatic components |

SMC , AIRTAC |

Japan. Taiwan |

|

2 |

PLC |

Beckhoff |

Germany |

|

3 |

Light sensor |

Omron/KEYENCE/SICK |

Japan |

|

4 |

Electrical components |

Schneider/Omron |

Germany/Japan |

|

5 |

Splitter |

GOIZPER |

Spanish |

|

6 |

Servo system |

INOVANCE |

China |

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 28 Nov, 2024 |

Related Products of this Company

-

Cylinder hot stamping machine(H-TC300K)

US $10500

-

Hot selling easy operation low cost

US $1250

-

Stalility hot stamping machine

US $8970

-

Greeting card hot stamping

US $2765

-

Hot selling IR Drying tunnel

US $2280

-

Easy operation hot selling Manual Hot

US $1397

-

Heightened Pneumatic hot stamping

US $3644

-

Spot UV Flat UV Curing Machine for paper

US $2129

-

Sublimation paper screen printing

US $5300

-

Manual 10 color garment screen printer

US $3529