| Model: | GS 1680 |

|---|---|

| Brand: | Goldensign |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Engraving & Etching Machine |

| Label: | laser engraver , Engraving Machine , cutting Machine |

| Price: |

US $4500

/ set

|

| Min. Order: | 1 set |

Product Description

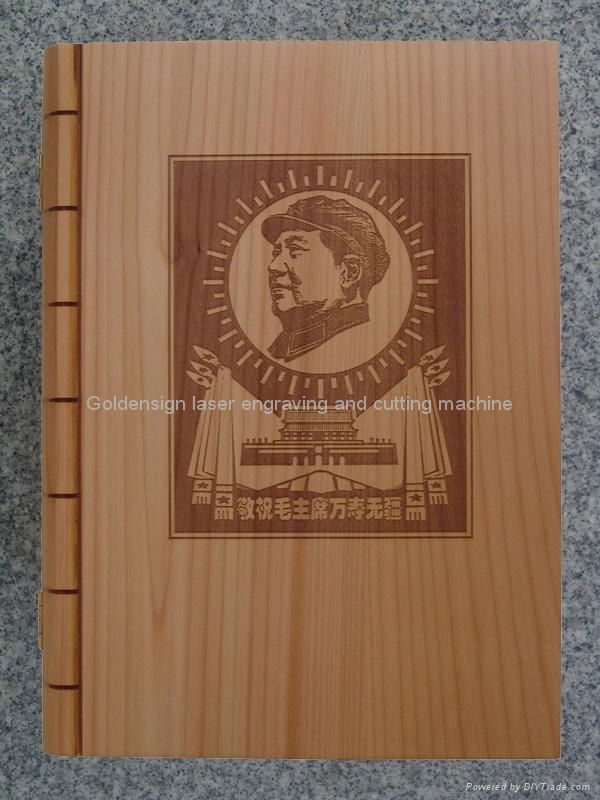

Description:

There are many materials can be engraved, such as wood block, bamboo product, acrylic sheet, glass, pvc sheet, double-color sheet, ceramic tile, rubber, plastic, marble, bowlder, crystal, leather and cloth. Etc. Nonferrous materials.

Good Features:

1.64-bit processor: It adopts the internationally advanced 64 digits, high speed DSP for control system of the GS laser engraving machine. The processing Capability and stability is highly improved.

2. Optimization of Arc: Stable S-style speed control software, quick and stable motion, which go very well with the automatic laser compensation, all these help the machine do a good job when cutting different parts, like straight lines, angles.

3. USB Interface: It supports the USB interface, with the GS series laser engraving machine, it's not necessary to connect to the computer, in this case, it not only enjoys high anti-interference, but also you can use only one computer to control many laser engraving machines.

4. Storage function: The mainboard has EMS Memory which enables the user to store more than 100 files.

5. Automatic Protection: There's automatic smoke/dust-ejecting system, water cooling system, if there's no water or the water flows in opposite direction, there'll be no laser, which protects the laser tube in an effective way.

Engraving size:900*600mm 1200*800mm 1600*1200mm 1200*600mm 1600*1200mm

Machine feature

1. This trademark laser cutting machine is largely used for cutting all kinds of labels, trade mark, embroidery samples

2. The machine is adoption of leading technology in this industry, seek cutting edge according to different colors of brim or positioning characteristic point of trademark.Realize automatically positioning cutting and punching. Copletely solve inevitable error caused by the manual position during the traditional laser cutting process.

3. It signs that laser technology and automatic technology as well as man-made visual intellectual technology combined harmony, according to using of pickup positioning system. There is no question that it can do a good help for getting, continuous and positive productivity and improving productivitiy as well.

4. Time is profit the software design with the shortest cutting path key point of automatic positioning cutter. It can save working time about 10-20% in average that is to say increasing the profit about 10-20%, comparing with software without the shortest cutting path design.

5. The achievement of high-speed and continuous curve cutting function is based on powerful data treatment capacity of top DSP technology, special design of software in computer and the perfect makeup of precise machinery system. It will neither change for cutting line nor distorting for curve cutting, in the case of high-speed running.

Technical parameter

Laser type:Hermetic and detached CO2 laser tube

Laser-wavelength:10600nm

Laser power: 30-150W

Working area: According to machine working size

Engraving speed ≤1200mms

Cutting speed: 0-4000mm/min

Repeat accuracy ≤0.05mm

Location precision <0.01mm

Shooting mode: CCD camera

Moving system: CNC controlling units

Working table: Thicker honeycomb working table

Graphic format: HPGL\PLT\BMP\JPEG\TIFF\TGA\DST\DXP\DXF\DWG\COK

Power supply: 220V/50HZ

whole power <1250W

Cooling system: Water-cooling and protection system

Auxiliary equipments: Exhaust-fans, air-exhaust pipe

Machine dimension: According to different model

Member Information

| Goldensign International Technology Co.,Ltd. | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 50318415 |

| Contact: | Harry Zhang (Manager) |

| Last Online: | 20 Jan, 2015 |

Related Products of this Company

-

Laser Engraver

US $3800