| Model: | PVC/PE film |

|---|---|

| Brand: | SUNHANG |

| Origin: | Made In China |

| Category: | Packaging , Printing & Paper / Packaging Materials / Composite Packaging Materials |

| Label: | Packaging material , composite material , PVC/PE Material |

| Price: |

US $2.8

/ kg

|

| Min. Order: | 3000 kg |

Product Description

|

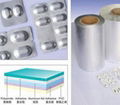

Pharma-grade PVC/PE film product and function introduction

|

Because of the PE has good heat seal ability, it can’t obstruct the gas but it can obstruct the fluid very well. It is good for packing fluid medicine.

Some factories used old glass bottles before, it has two fatal defects:

Some factories used old glass bottles before, it has two fatal defects:

1.It is easy broken when you are opening.

2.The fluid in it is easy to expanded and crash the bottle when it has fermented. So it will damage the product packaging.

Officinal PVC/PE coated film has taken away from the two defects above. It is mainly produced by officinal PVC film, then heat seal the PE film. During the producing, the temperature, coated quantity and solid time are measured strictly to make sure that the product can meet the standard of the same product in the international. The heat seal ability is 4 times higher than common PVC film. It also has good rigidty, flexility, compression resistance and dilatability. It is suit for packing all kinds of fluid medicine.

PS: If there is any volatile, please consult to use PVC/PVDC/PE coated film. This product has high obstruct ability. It can complete avoid the volatilization of the shortage quantity or other effect that affected the capability of the medicine.

Officinal PVC/PE coated film has taken away from the two defects above. It is mainly produced by officinal PVC film, then heat seal the PE film. During the producing, the temperature, coated quantity and solid time are measured strictly to make sure that the product can meet the standard of the same product in the international. The heat seal ability is 4 times higher than common PVC film. It also has good rigidty, flexility, compression resistance and dilatability. It is suit for packing all kinds of fluid medicine.

PS: If there is any volatile, please consult to use PVC/PVDC/PE coated film. This product has high obstruct ability. It can complete avoid the volatilization of the shortage quantity or other effect that affected the capability of the medicine.

Use parameter (our product is different from other supplier’s)

Blister temperature: 110℃ — 150℃, normally 5℃ higher than PVC , Sealing temperature 170℃ — 180℃

Negative pressure: 2.4 — 4 kg

Member Information

| Sunhang Pharmaceutical Machinery Co., Limited | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 13917598598 |

| Contact: | Tony Zhu (Manager of export) |

| Last Online: | 08 Jan, 2025 |

Related Products of this Company

-

Cold Forming Alu Alu Foils

US $4.8

-

PVC/PE FOR ORAL LIQUID

US $2.5

-

Pharma Grade PVC RIGID FILM

US $1.85

-

PVC/PE/PVDC Laminated Film

US $3.55

-

PET/AL/PE Laminated Film

US $4.8

-

PVC/PE FOR SUPPOSITORY

US $2.55

-

PVC/PE Laminated Film

US $2.85

-

Pharma-grade PVC/PE/PVDC coated film

US $3.5

-

PTP Lidding Foil for Blister Packing

US $4.8